Insulation Clip Pins

Insulation pins and insulation clips are essential tools in the field of insulation installation. They play a crucial role in securing insulation materials in place, ensuring proper thermal and acoustic insulation. In this comprehensive exploration, we will take a closer look at insulation pins and insulation clips, their characteristics, functions, applications, and more.

Contact

Product Detail

I. Introduction to Insulation Pins and Insulation Clips

Insulation pins and clips are designed to provide a reliable and durable means of attaching insulation materials to various surfaces. These fastening devices come in different shapes, sizes, and materials to meet the diverse needs of different insulation applications.

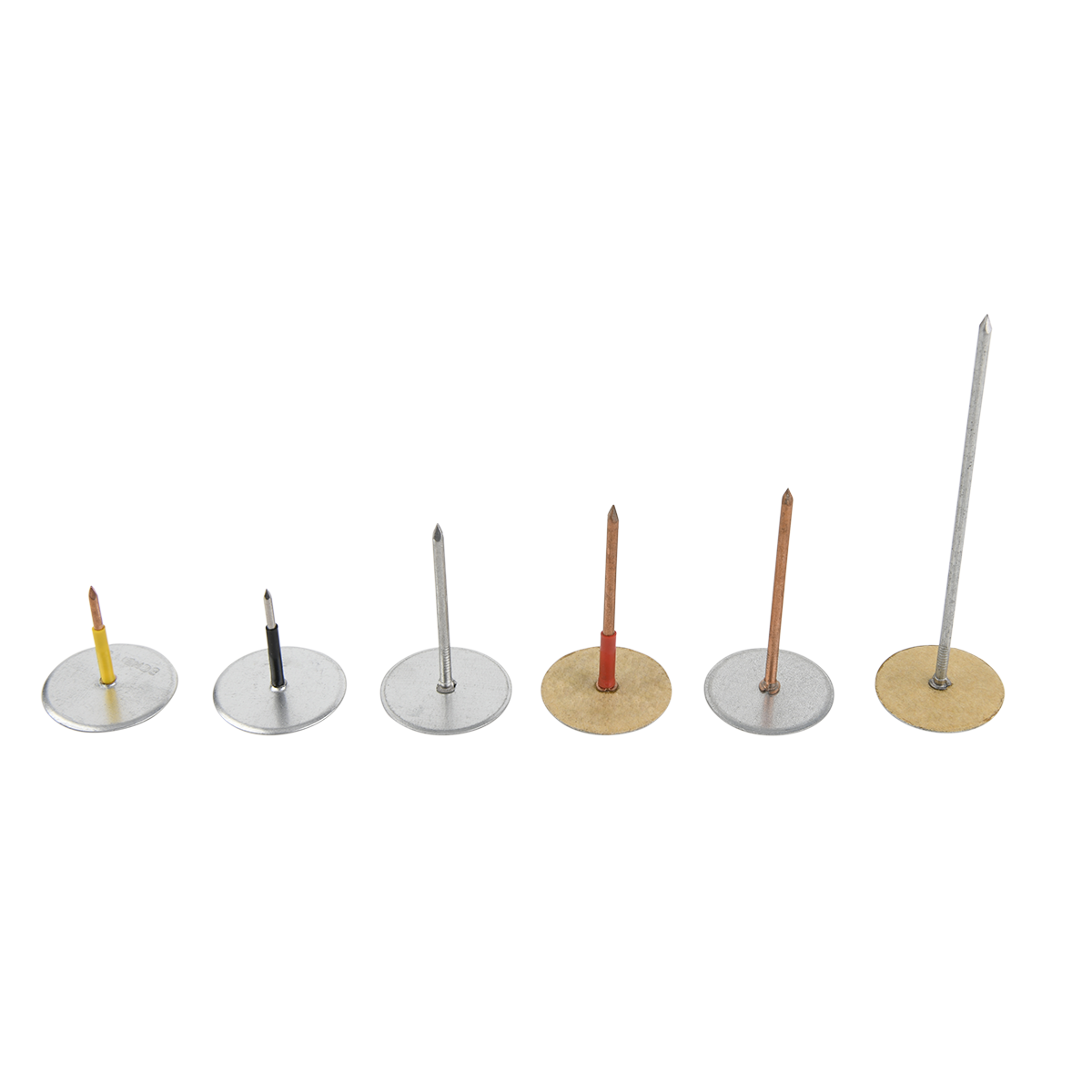

Insulation pins are typically long, slender rods with a sharp point at one end and a head at the other. They are inserted through the insulation material and into the underlying surface to hold the insulation in place. Insulation clips, on the other hand, are usually U-shaped or C-shaped devices that grip the insulation material and attach it to the surface.

Both insulation pins and clips are important for ensuring the effectiveness of insulation systems. They prevent the insulation from shifting or coming loose, which can lead to reduced insulation performance and increased energy consumption.

II. Materials and Construction of Insulation Pins

A. Materials Used

1. Stainless Steel: Stainless steel insulation pins are highly durable and resistant to corrosion. They are suitable for use in harsh environments and can withstand exposure to moisture, chemicals, and extreme temperatures. Stainless steel pins are often used in industrial applications and outdoor installations.

2. Galvanized Steel: Galvanized steel insulation pins offer good strength and corrosion resistance. They are coated with a layer of zinc to protect against rust and are commonly used in construction and building insulation.

3. Plastic: Plastic insulation pins are lightweight and easy to install. They are available in different colors and can be used in applications where aesthetics are important. Plastic pins are often used in residential insulation and interior installations.

B. Construction Features

1. Sharp Point: The sharp point of an insulation pin allows it to easily penetrate through the insulation material and into the underlying surface. This ensures a secure attachment and minimizes the risk of the insulation coming loose.

2. Head Design: The head of an insulation pin is designed to hold the insulation in place. It can be flat, domed, or have other shapes depending on the application. Some heads may also have features such as barbs or serrations to increase the holding power.

3. Length and Diameter: Insulation pins come in different lengths and diameters to accommodate different insulation thicknesses and installation requirements. Longer pins may be needed for thicker insulation or when attaching insulation to deeper surfaces. The diameter of the pin should be appropriate for the insulation material and the surface it is being attached to.

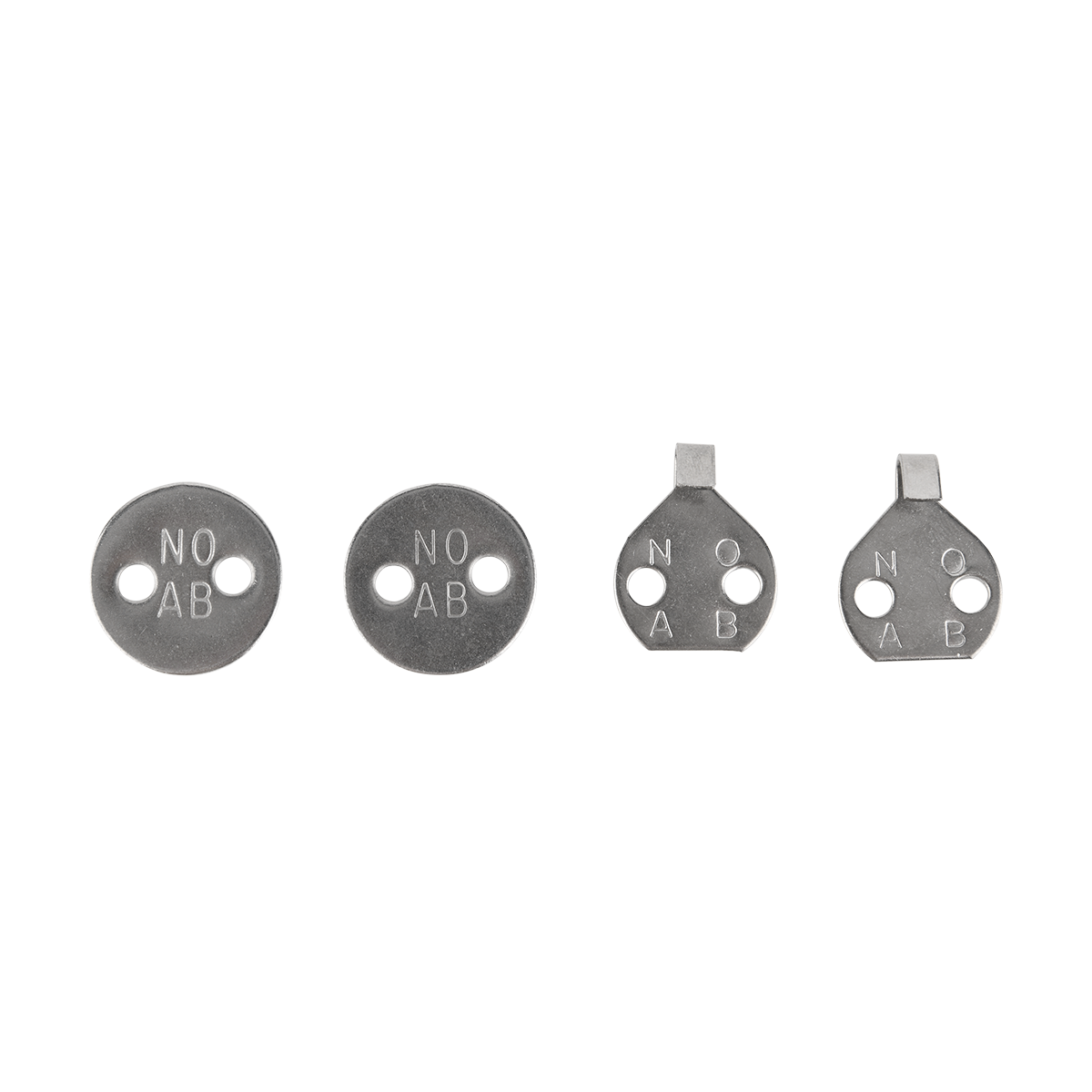

III. Materials and Construction of Insulation Clips

A. Materials Used

1. Metal: Metal insulation clips are typically made of stainless steel or galvanized steel. They offer high strength and durability and are suitable for use in heavy-duty applications. Metal clips can withstand high temperatures and are often used in industrial insulation.

2. Plastic: Plastic insulation clips are lightweight and easy to install. They are available in different colors and can be used in applications where aesthetics are important. Plastic clips are often used in residential insulation and interior installations.

B. Construction Features

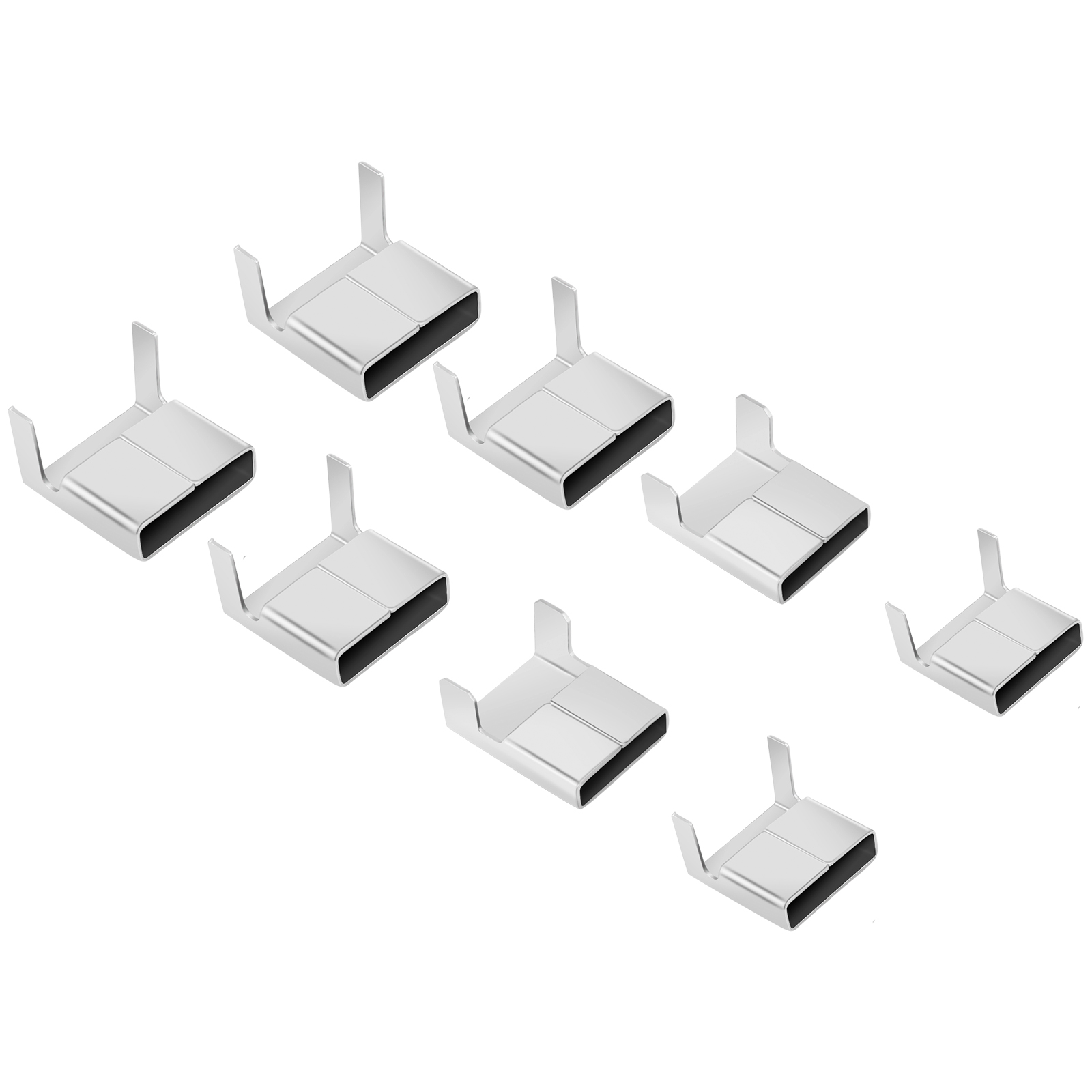

1. Clip Design: Insulation clips come in different designs, such as U-shaped, C-shaped, or J-shaped. The clip design should be appropriate for the insulation material and the surface it is being attached to. The clip should grip the insulation firmly without causing damage.

2. Spring Action: Some insulation clips have a spring action that provides additional holding power. The spring action allows the clip to expand and contract as needed, accommodating different insulation thicknesses.

3. Mounting Options: Insulation clips can be mounted using screws, nails, adhesives, or other fastening methods. The mounting option should be appropriate for the surface and installation requirements.

IV. Functions and Benefits of Insulation Pins

A. Securing Insulation

The primary function of insulation pins is to hold insulation materials in place. By penetrating through the insulation and into the underlying surface, pins create a secure attachment that resists movement and vibration. This helps to ensure that the insulation remains in place and provides the desired level of thermal and acoustic insulation.

B. Preventing Air Leakage

Insulation pins can also help to prevent air leakage. When insulation is properly attached with pins, there are fewer gaps and openings through which air can pass. This helps to improve the energy efficiency of a building or structure by reducing heat transfer through convection.

C. Enhancing Durability

Insulation pins are designed to be durable and long-lasting. They can withstand the rigors of installation and use, as well as exposure to environmental factors such as moisture, temperature changes, and UV radiation. By providing a reliable means of attachment, pins help to extend the lifespan of the insulation and reduce the need for frequent maintenance or replacement.

D. Versatility

Insulation pins are available in different materials, sizes, and lengths, making them suitable for a wide range of insulation applications. They can be used with different types of insulation materials, including fiberglass, mineral wool, foam board, and more. Pins can also be used on different surfaces, such as wood, metal, concrete, and drywall.

E. Easy Installation

Insulation pins are relatively easy to install. They can be inserted through the insulation and into the underlying surface using a hammer, screwdriver, or other hand tools. Some pins may also be installed using power tools, such as a drill or pneumatic gun. The installation process is quick and straightforward, saving time and labor costs.

V. Functions and Benefits of Insulation Clips

A. Secure Attachment

Insulation clips provide a secure and reliable means of attaching insulation materials to surfaces. They grip the insulation firmly without causing damage and hold it in place even under stress and vibration. This helps to ensure that the insulation remains effective and provides the desired level of insulation performance.

B. Easy Installation

Insulation clips are easy to install and can be attached to surfaces using screws, nails, adhesives, or other fastening methods. Some clips may also be designed for snap-on installation, making them even more convenient and quick to install. The installation process is simple and requires minimal tools and expertise.

C. Versatility

Insulation clips are available in different designs and sizes, making them suitable for a wide range of insulation applications. They can be used with different types of insulation materials and on different surfaces, providing flexibility and versatility in insulation installation.

D. Cost-Effective

Insulation clips are a cost-effective solution for insulation installation. They are relatively inexpensive compared to other fastening methods and can help to reduce installation costs. Additionally, clips can be reused if the insulation needs to be replaced or removed, further reducing costs.

E. Aesthetic Appeal

Some insulation clips are designed to be aesthetically pleasing and can enhance the appearance of the insulation installation. They can be available in different colors and finishes to match the decor of the building or structure.

VI. Applications of Insulation Pins and Insulation Clips

A. Building Insulation

Insulation pins and clips are widely used in building insulation applications. They can be used to attach insulation materials to walls, ceilings, floors, and roofs of buildings. Pins and clips help to ensure that the insulation remains in place and provides effective thermal and acoustic insulation, reducing energy consumption and improving indoor comfort.

B. Industrial Insulation

In industrial settings, insulation pins and clips are used to insulate pipes, ducts, vessels, and other equipment. They help to maintain the temperature of process fluids and reduce heat loss or gain, improving the efficiency of industrial processes and reducing energy consumption. Industrial insulation applications often require durable and high-temperature-resistant fastening devices, such as stainless steel pins and clips.

C. Automotive Insulation

Insulation pins and clips are also used in the automotive industry for soundproofing and thermal insulation. They can be used to attach insulation materials to the interior of vehicles, reducing noise and improving passenger comfort. Automotive insulation applications often require lightweight and easy-to-install fastening devices, such as plastic pins and clips.

D. Aerospace Insulation

In the aerospace industry, insulation pins and clips are used to insulate aircraft cabins and other components. They help to maintain a comfortable temperature for passengers and crew and reduce noise levels inside the aircraft. Aerospace insulation applications often require lightweight, high-strength, and fire-resistant fastening devices.

E. Other Applications

Insulation pins and clips can also be used in other applications, such as refrigeration systems, electrical insulation, and packaging. Their versatility and reliability make them suitable for a wide range of insulation needs.

VII. Choosing the Right Insulation Pins and Insulation Clips

A. Consideration of Insulation Type

When choosing insulation pins and clips, it is important to consider the type of insulation material being used. Different insulation materials may require different types of fastening devices based on their thickness, density, and other characteristics. For example, fiberglass insulation may require pins with a different diameter or length than mineral wool insulation.

B. Installation Surface

The surface on which the insulation will be installed is also an important consideration. Different surfaces may require different types of fastening devices based on their texture, strength, and other properties. For example, a smooth metal surface may require clips with a stronger grip than a rough concrete surface.

C. Environmental Conditions

The environmental conditions in which the insulation will be installed should also be taken into account. If the insulation will be exposed to moisture, chemicals, high temperatures, or other harsh conditions, it may be necessary to choose fastening devices that are resistant to these conditions. For example, stainless steel pins and clips may be a better choice for applications where the insulation will be exposed to moisture or corrosive substances.

D. Load Requirements

The load that the insulation will be subjected to is another important factor to consider. If the insulation will be supporting heavy objects or subjected to high winds or other forces, it may be necessary to choose fastening devices with a higher holding power. For example, pins with a larger diameter or clips with a stronger spring action may be needed for applications where the insulation will be subjected to heavy loads.

E. Aesthetic Requirements

In some applications, aesthetic considerations may also play a role in choosing insulation pins and clips. If the insulation will be visible, it may be necessary to choose fastening devices that are aesthetically pleasing and blend in with the surrounding decor. For example, plastic pins and clips in different colors may be a better choice for interior installations where aesthetics are important.

VIII. Installation Tips for Insulation Pins and Insulation Clips

A. Preparation

Before installing insulation pins and clips, it is important to prepare the surface and insulation materials. The surface should be clean, dry, and free of any debris or contaminants. The insulation should be cut to the appropriate size and shape to fit the area being insulated.

B. Spacing and Placement

Insulation pins and clips should be spaced evenly and placed at appropriate intervals to ensure a secure attachment. The spacing and placement will depend on the type of insulation material, the surface being insulated, and the load requirements. Refer to the manufacturer's instructions or consult a professional for specific recommendations on spacing and placement.

C. Installation Tools

The appropriate installation tools should be used to install insulation pins and clips. For pins, a hammer, screwdriver, or other hand tools may be used. For clips, screws, nails, adhesives, or other fastening methods may be used. Power tools may also be used for some applications, but care should be taken to ensure that they are used safely and correctly.

D. Inspection and Maintenance

After installation, it is important to inspect the insulation pins and clips to ensure that they are properly installed and providing a secure attachment. Regular inspection and maintenance can help to detect any problems early and prevent damage to the insulation or the underlying surface. If any problems are detected, they should be addressed promptly to ensure the effectiveness of the insulation system.

IX. Conclusion

Insulation pins and clips are essential tools for insulation installation. They provide a reliable and durable means of attaching insulation materials to surfaces, ensuring proper thermal and acoustic insulation. By understanding the characteristics, functions, applications, and installation tips of insulation pins and clips, you can choose the right fastening devices for your insulation needs and ensure a successful installation. Whether you are working on a building project, industrial installation, or other application, insulation pins and clips can help you achieve effective insulation and energy savings.