Insulation Pin for Curtain Wall Overview

Insulation pins play a crucial role in curtain wall systems, providing effective thermal insulation

Contact

Product Detail

Insulation pins play a crucial role in curtain wall systems, providing effective thermal insulation and ensuring the stability and durability of the structure. In this in-depth exploration, we will examine insulation pins for curtain walls in detail, covering their characteristics, functions, installation methods, and more.

I. Introduction to Insulation Pins for Curtain Wall

Curtain walls are an essential part of modern architecture, providing both aesthetic appeal and functional benefits. However, to achieve optimal performance, curtain walls need to be properly insulated to prevent heat transfer, condensation, and noise transmission. Insulation pins are an important component of curtain wall insulation systems, helping to hold the insulation materials in place and ensure their effectiveness.

Insulation pins for curtain walls are typically made of materials such as stainless steel, nylon, or polypropylene. They are designed to be inserted through the insulation material and into the curtain wall frame or support structure, providing a secure connection and preventing the insulation from shifting or sagging.

The main purpose of insulation pins for curtain walls is to improve the energy efficiency of the building by reducing heat transfer through the curtain wall. By providing a thermal break between the interior and exterior of the building, insulation pins help to maintain a comfortable indoor temperature and reduce heating and cooling costs.

II. Characteristics of Insulation Pins for Curtain Wall

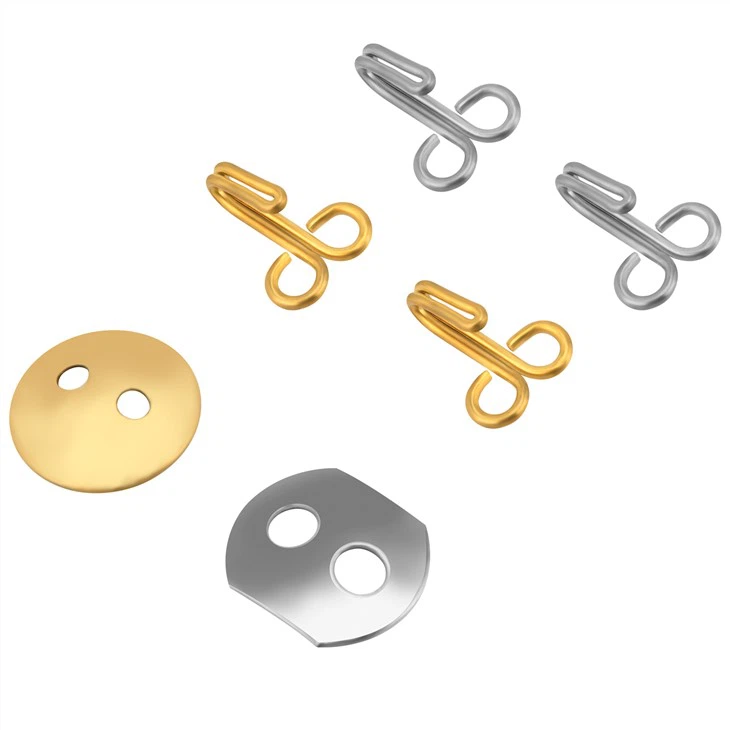

A. Material Options

Stainless Steel: Stainless steel insulation pins are highly durable and resistant to corrosion. They are suitable for use in harsh environments and can withstand exposure to moisture, chemicals, and temperature extremes. Stainless steel pins are also strong and can support heavy insulation materials, making them ideal for large-scale curtain wall projects.

Nylon: Nylon insulation pins are lightweight and easy to install. They are resistant to moisture and chemicals, and offer good insulation properties. Nylon pins are often used in smaller curtain wall projects or where weight is a concern.

Polypropylene: Polypropylene insulation pins are also lightweight and offer good insulation properties. They are resistant to moisture and chemicals, and can be used in a variety of curtain wall applications. Polypropylene pins are often less expensive than stainless steel or nylon pins, making them a cost-effective option for some projects.

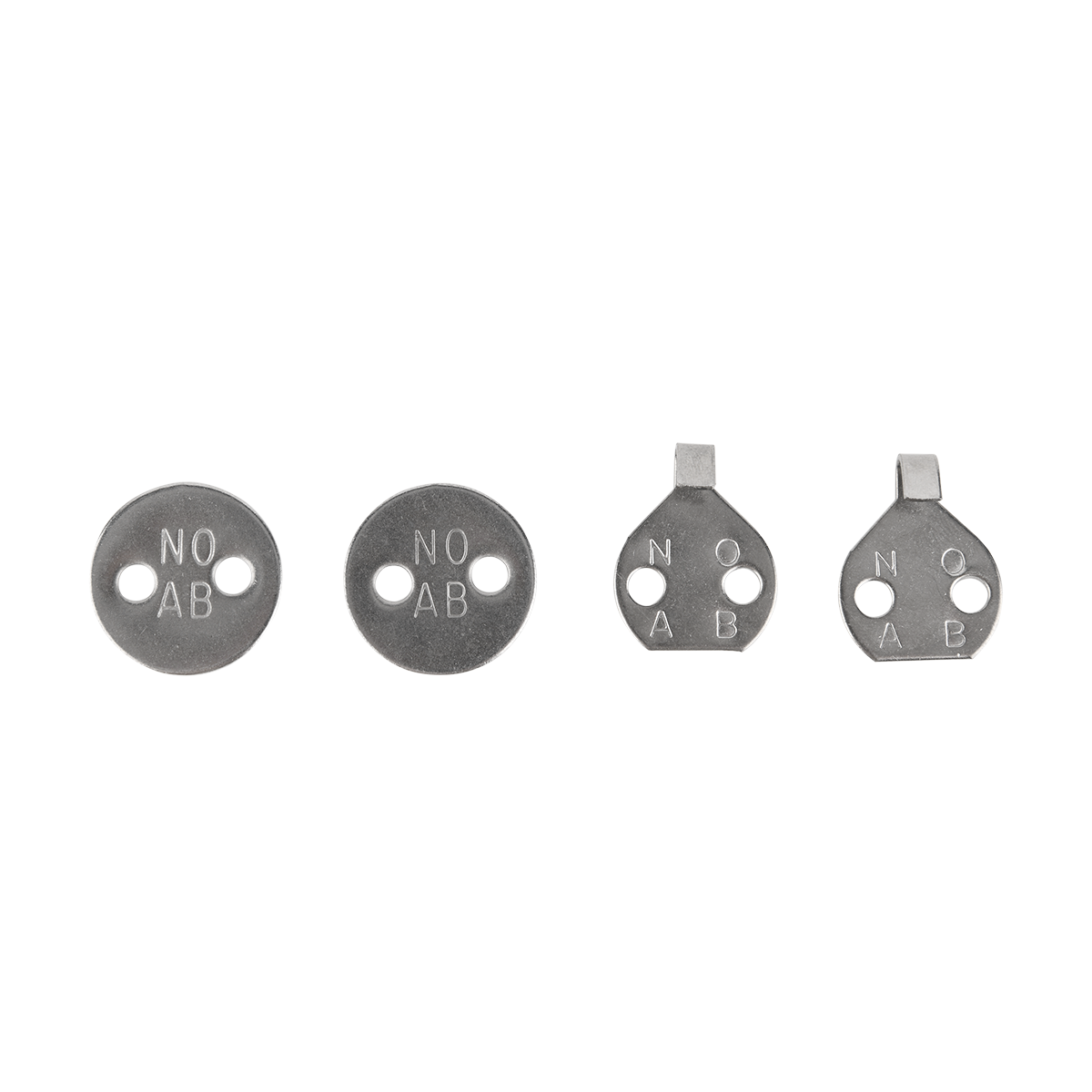

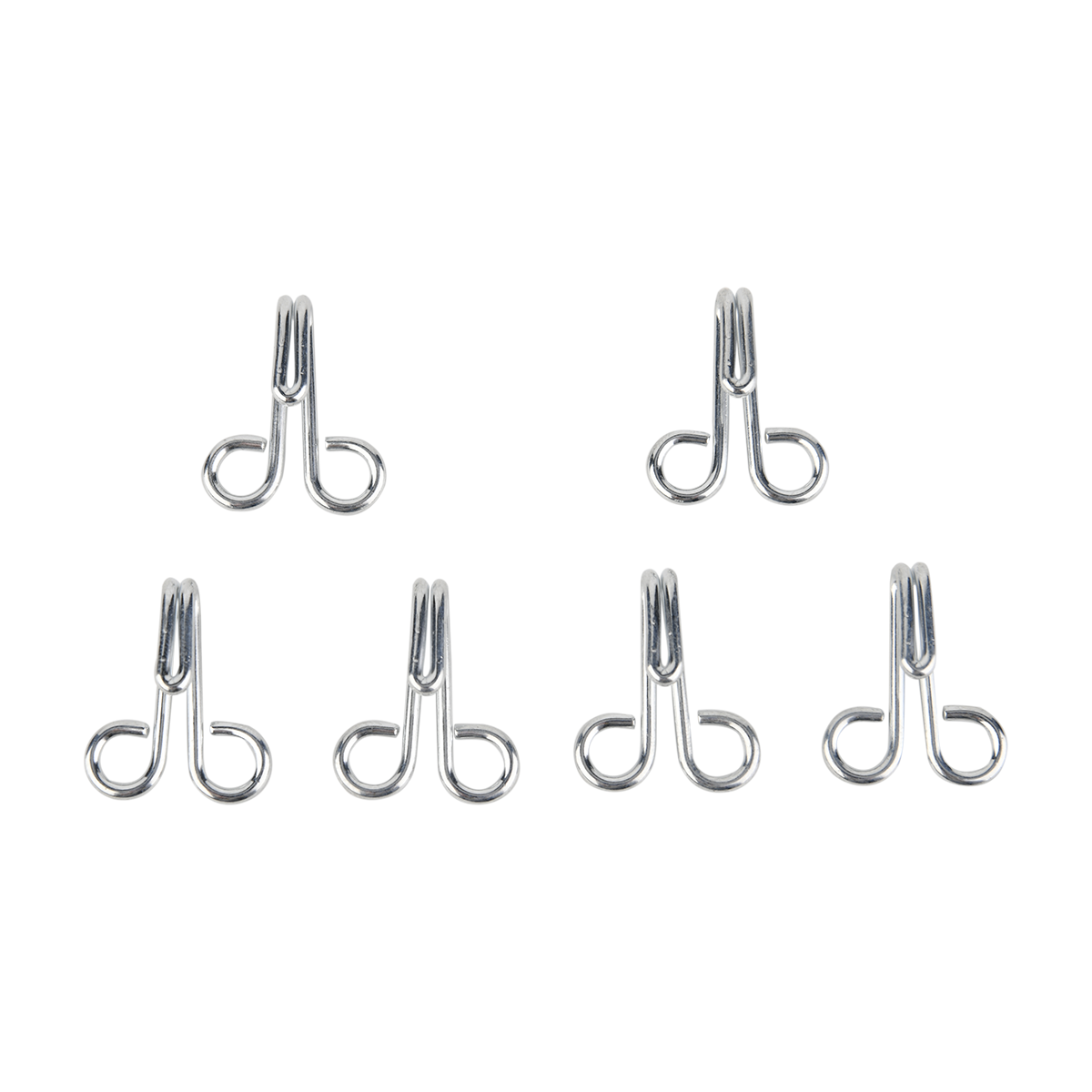

B. Design Features

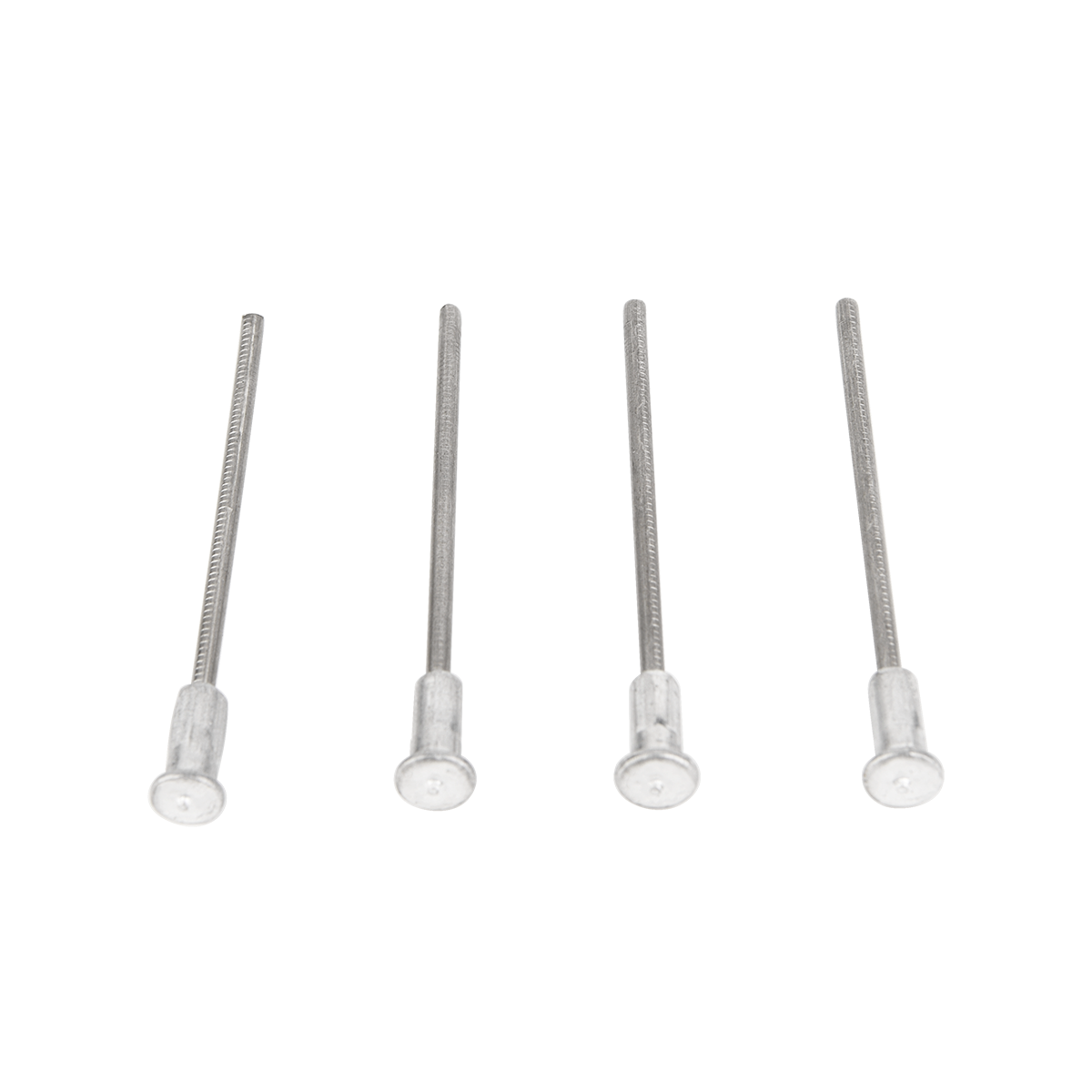

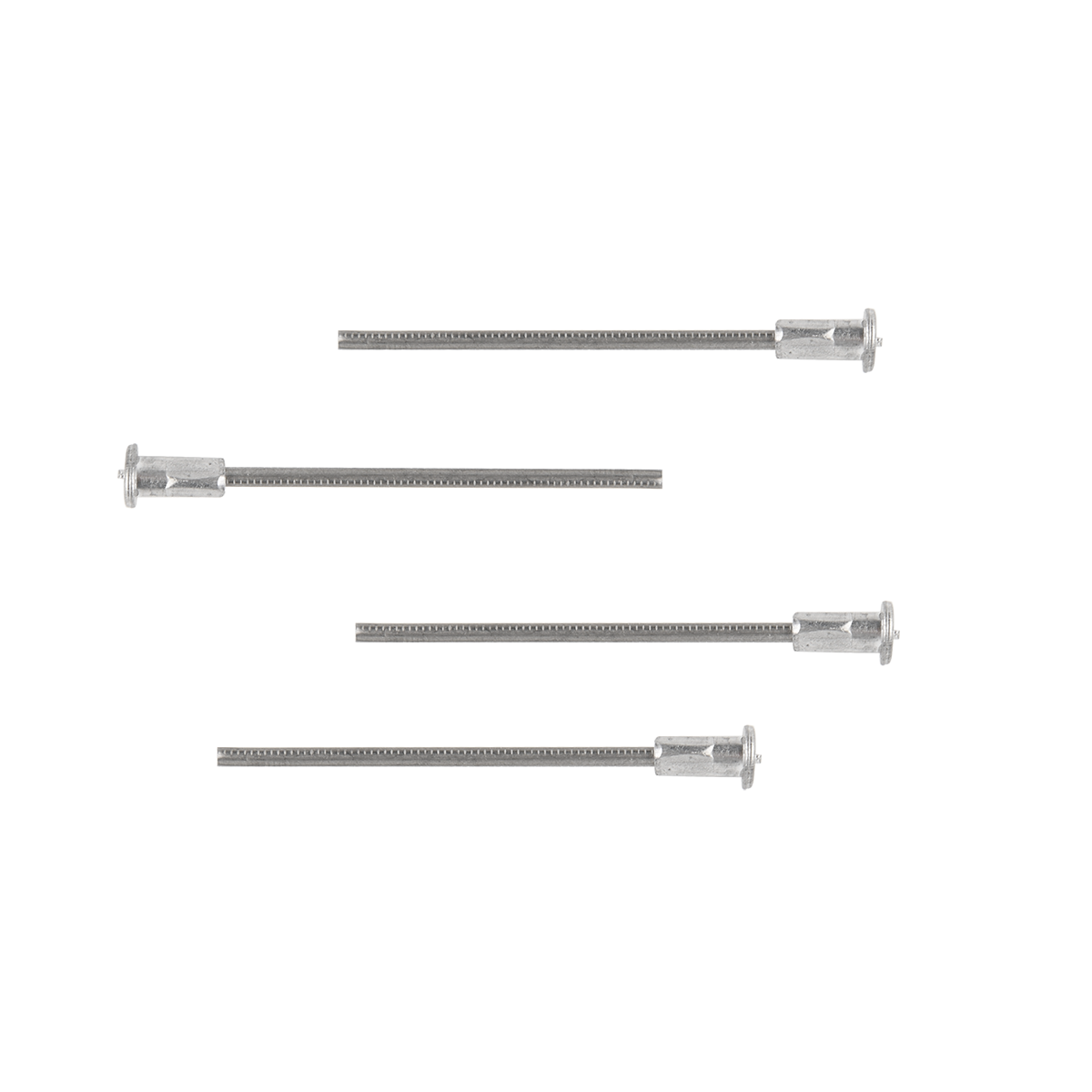

Sharp Point: The sharp point of an insulation pin makes it easy to insert through the insulation material and into the curtain wall frame. This ensures a secure connection and minimizes the risk of damage to the insulation or the frame.

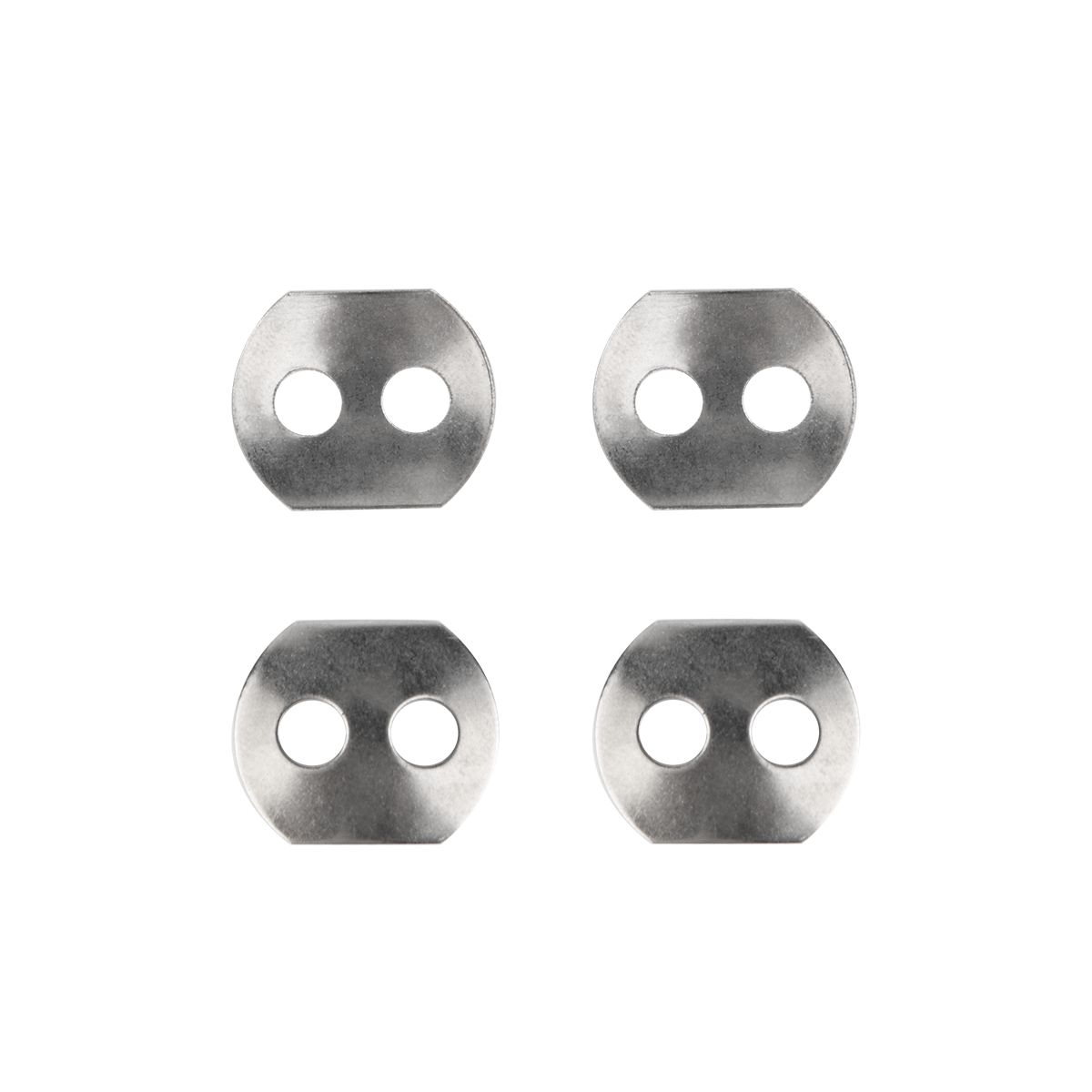

Head Design: The head of an insulation pin is designed to hold the insulation material in place and prevent it from slipping or sagging. Some pins have a flat head, while others may have a domed or rounded head for added stability.

Length and Diameter: Insulation pins for curtain walls come in a variety of lengths and diameters to accommodate different insulation thicknesses and curtain wall designs. The length of the pin should be sufficient to penetrate through the insulation and into the frame by a certain depth to ensure a secure connection. The diameter of the pin should be appropriate for the insulation material and the frame to prevent excessive compression or damage.

C. Insulation Properties

Insulation pins for curtain walls are designed to provide thermal insulation by creating a thermal break between the interior and exterior of the building. The insulation properties of the pins depend on the material they are made of and their design. Some pins are filled with insulating materials such as foam or fiberglass to enhance their insulation performance.

III. Functions of Insulation Pins for Curtain Wall

A. Thermal Insulation

The primary function of insulation pins for curtain walls is to provide thermal insulation. By creating a thermal break between the interior and exterior of the building, insulation pins help to reduce heat transfer and maintain a comfortable indoor temperature. This can result in significant energy savings and reduce the building's carbon footprint.

B. Sound Insulation

In addition to thermal insulation, insulation pins for curtain walls can also provide sound insulation. By reducing the transmission of sound through the curtain wall, insulation pins can help to create a quieter indoor environment and improve the comfort of the building's occupants.

C. Structural Support

Insulation pins for curtain walls also provide structural support by holding the insulation materials in place. This helps to prevent the insulation from sagging or shifting, which can affect the performance and appearance of the curtain wall. Insulation pins can also help to distribute the weight of the insulation evenly across the curtain wall frame, reducing stress on the structure.

D. Waterproofing

Some insulation pins for curtain walls are designed to provide waterproofing by creating a seal between the insulation and the curtain wall frame. This helps to prevent water from penetrating the curtain wall and causing damage to the interior of the building.

IV. Installation Methods for Insulation Pins for Curtain Wall

A. Preparation

Before installing insulation pins for curtain walls, it is important to prepare the installation area. This may involve cleaning the curtain wall frame and ensuring that it is free of debris or contaminants. The insulation material should also be cut to the appropriate size and shape to fit the curtain wall design.

B. Insertion of Pins

To install the insulation pins, start by positioning the insulation material against the curtain wall frame. Then, using a hammer or other suitable tool, insert the pins through the insulation and into the frame. Make sure to insert the pins at a perpendicular angle to ensure a secure connection. The depth of insertion should be sufficient to provide a strong hold, but not so deep that it damages the frame or the insulation.

C. Spacing and Layout

The spacing and layout of insulation pins for curtain walls will depend on the insulation thickness, the curtain wall design, and the installation requirements. Generally, pins should be spaced evenly across the surface of the insulation to ensure a uniform distribution of load. Refer to the manufacturer's instructions or consult a professional for specific recommendations on spacing and layout.

D. Finishing Touches

Once the insulation pins are installed, check to make sure that the insulation is firmly in place and there are no gaps or loose areas. If necessary, add additional pins or adjust the spacing to ensure a proper installation. Finally, finish the installation by covering the pins with a suitable finishing material, such as tape or caulking, to protect them from moisture and other environmental factors.

V. Considerations for Choosing Insulation Pins for Curtain Wall

A. Compatibility with Insulation Material

When choosing insulation pins for curtain walls, it is important to ensure that they are compatible with the insulation material being used. Different insulation materials may have different thicknesses, densities, and mechanical properties, so it is important to select pins that are designed to work with the specific insulation.

B. Load Capacity

The load capacity of the insulation pins is another important consideration. Depending on the size and weight of the curtain wall and the insulation material, the pins may need to support significant loads. Make sure to select pins that have a sufficient load capacity to handle the expected loads and ensure a secure installation.

C. Environmental Conditions

The environmental conditions in which the curtain wall will be installed should also be taken into account. If the curtain wall will be exposed to moisture, chemicals, temperature extremes, or other harsh conditions, it is important to choose insulation pins that are resistant to these conditions. Stainless steel pins are often a good choice for harsh environments, while nylon or polypropylene pins may be more suitable for milder conditions.

D. Aesthetic Considerations

In some cases, aesthetic considerations may also play a role in choosing insulation pins for curtain walls. If the curtain wall will be visible from the interior or exterior of the building, it may be desirable to choose pins that are discreet or have a color that matches the curtain wall frame or surrounding architecture.

E. Cost

Finally, cost is always a consideration when choosing insulation pins for curtain walls. While it is important to select high-quality pins that will provide a reliable installation, it is also important to consider the cost and ensure that it fits within the budget for the project. Compare different options and consider the long-term benefits and durability of the pins when making a decision.

VI. Maintenance and Care of Insulation Pins for Curtain Wall

A. Inspection

Regular inspection of insulation pins for curtain walls is important to ensure their continued effectiveness. Check for any signs of damage, such as bent or broken pins, or loose insulation. If any issues are found, they should be addressed promptly to prevent further damage or loss of insulation performance.

B. Cleaning

If the insulation pins become dirty or contaminated, they can be cleaned using a mild detergent and water. Avoid using harsh chemicals or abrasives, as these can damage the pins or the insulation. After cleaning, make sure to dry the pins thoroughly before reinstalling the insulation.

C. Replacement

If insulation pins for curtain walls become damaged or worn out, they should be replaced promptly. This will ensure that the insulation remains securely in place and continues to provide the desired level of thermal and acoustic insulation. When replacing pins, make sure to use the same type and size as the original pins to ensure a proper fit.

Insulation pins for curtain walls are an important component of curtain wall insulation systems, providing thermal insulation, sound insulation, structural support, and waterproofing. By understanding the characteristics, functions, installation methods, and considerations for choosing insulation pins for curtain walls, you can ensure a high-quality installation that meets your specific needs and requirements. Whether you are working on a new construction project or renovating an existing building, insulation pins for curtain walls can help to improve the energy efficiency, comfort, and durability of your curtain wall system.