Insulation Pins for Metal

Insulation pins for metal play a crucial role in ensuring effective insulation in applications where metal surfaces are involved. These pins are specifically designed to secure insulation materials to metal substrates, providing a reliable and durable solution for thermal and acoustic insulation. In this extensive introduction, we will explore the various aspects of insulation pins for metal, including their design, features, applications, benefits, and installation methods.

Contact

Product Detail

Design and Features:

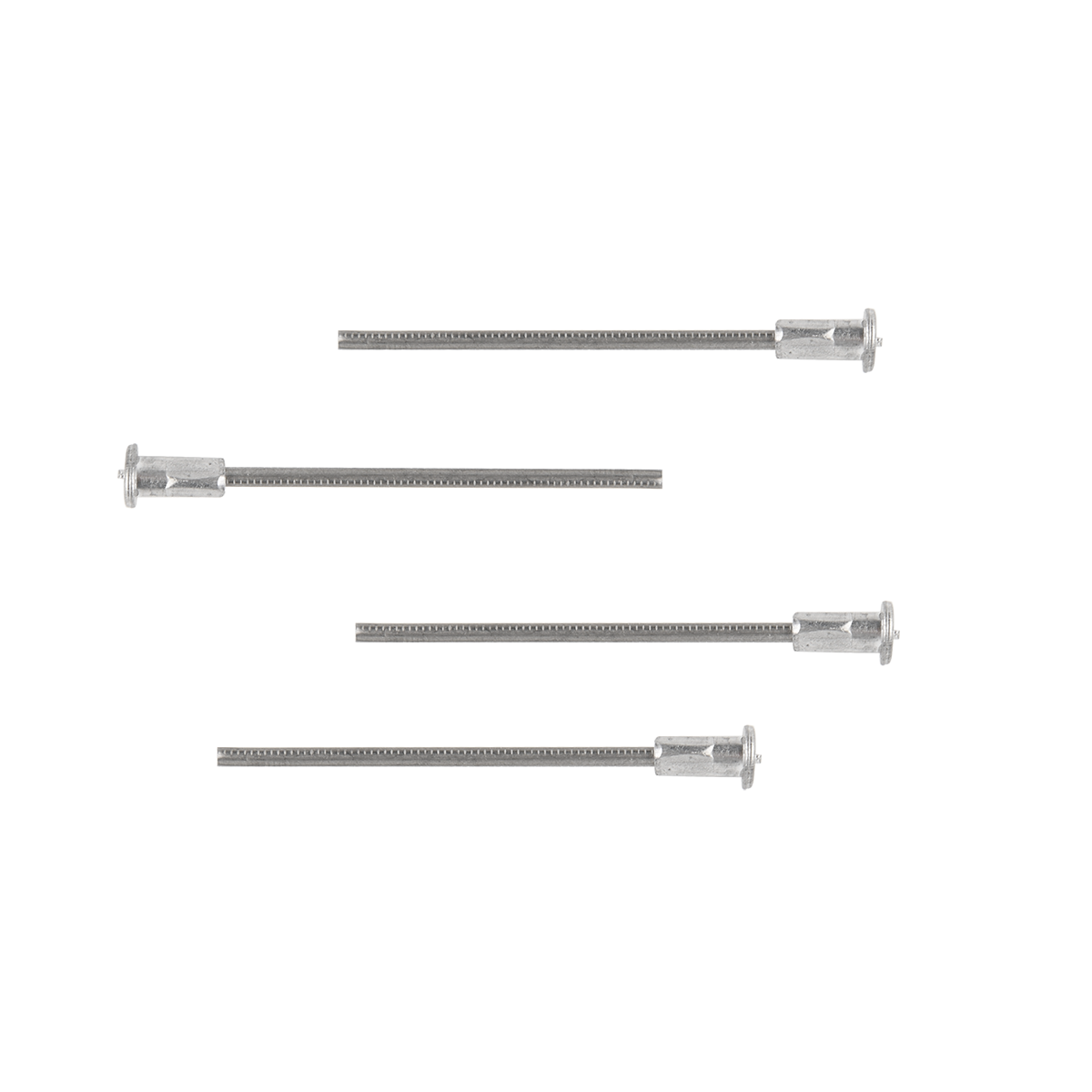

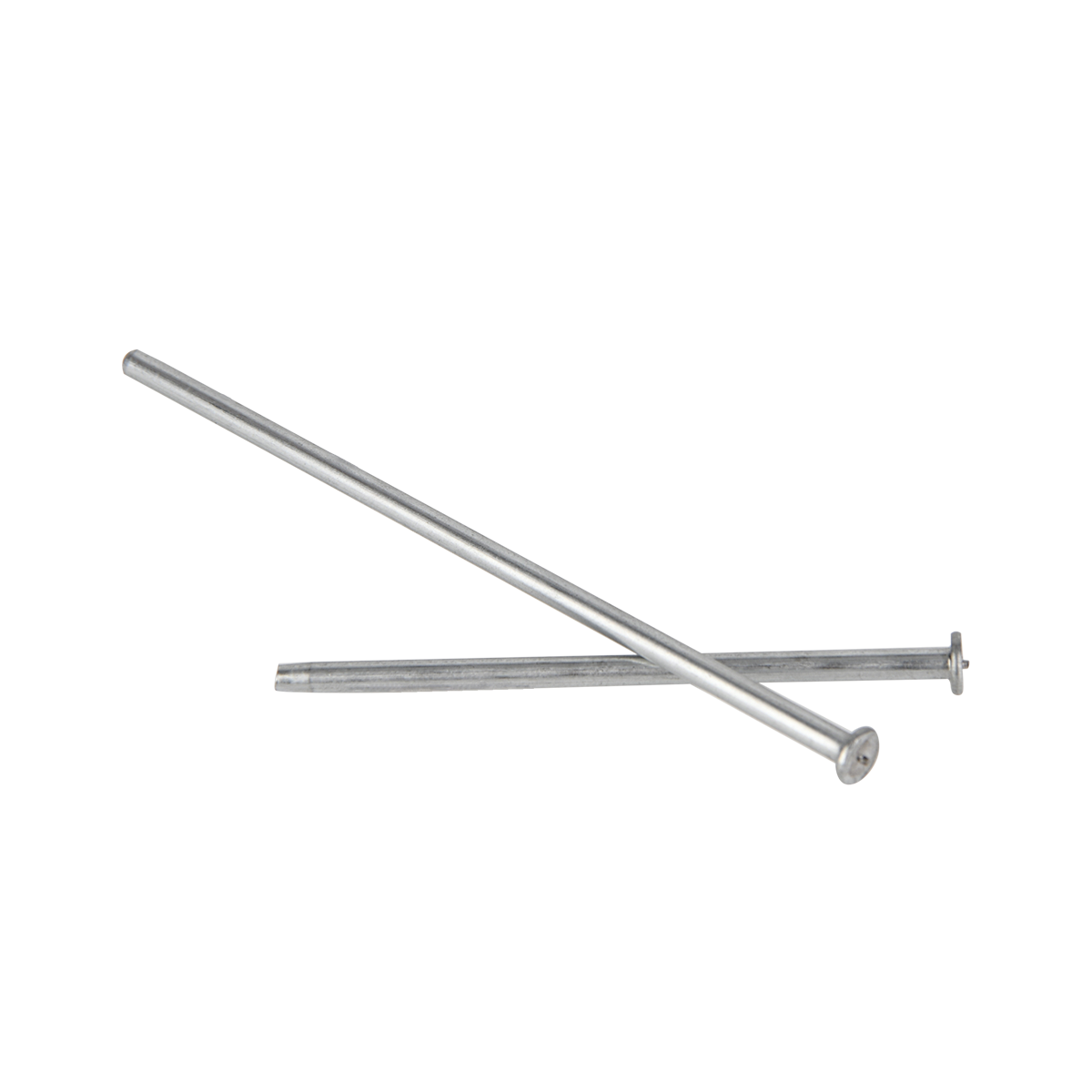

Insulation pins for metal are typically made of materials that are compatible with metal surfaces and can withstand the rigors of different environments. Common materials used for these pins include stainless steel, galvanized steel, and plastic. The choice of material depends on factors such as the specific application, environmental conditions, and durability requirements.

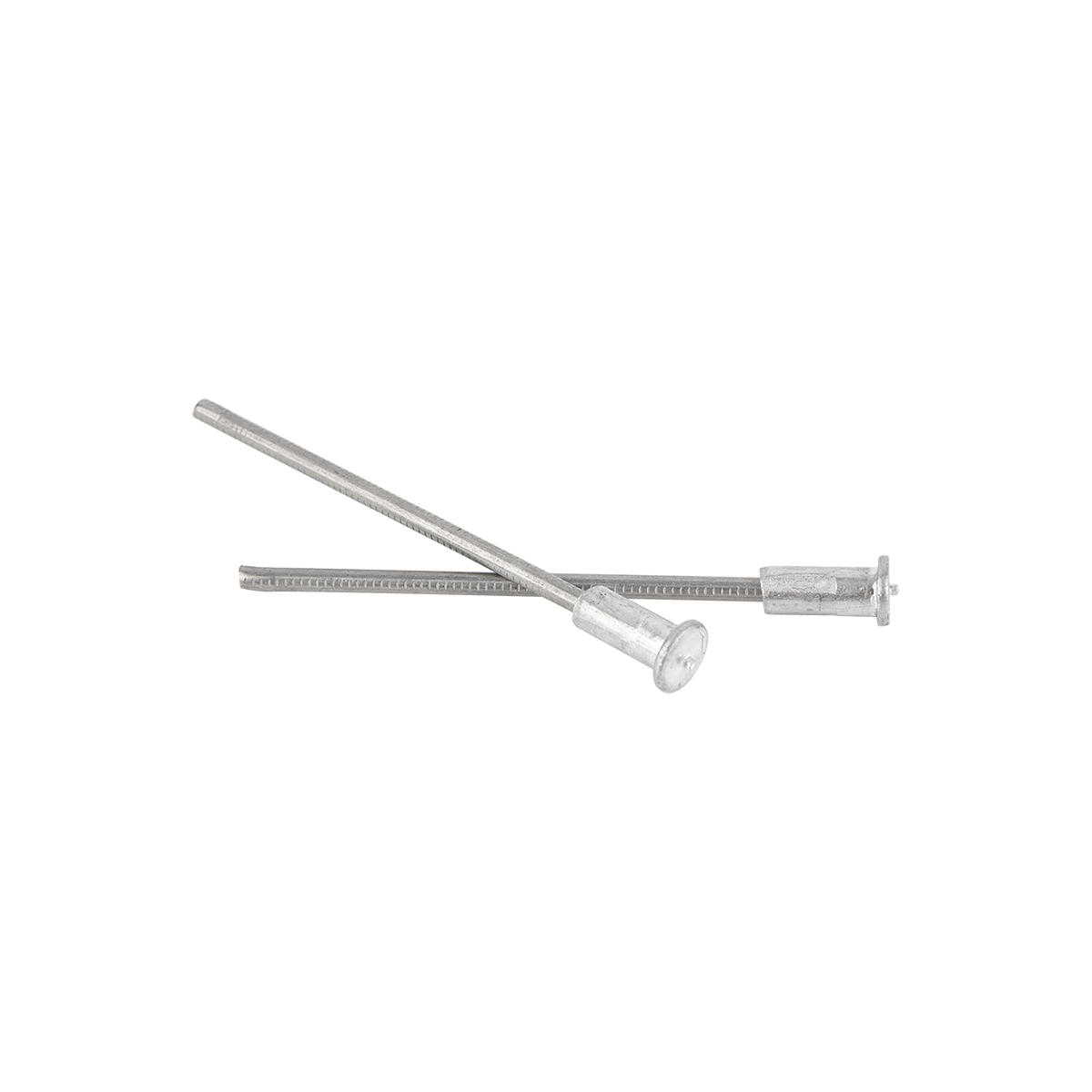

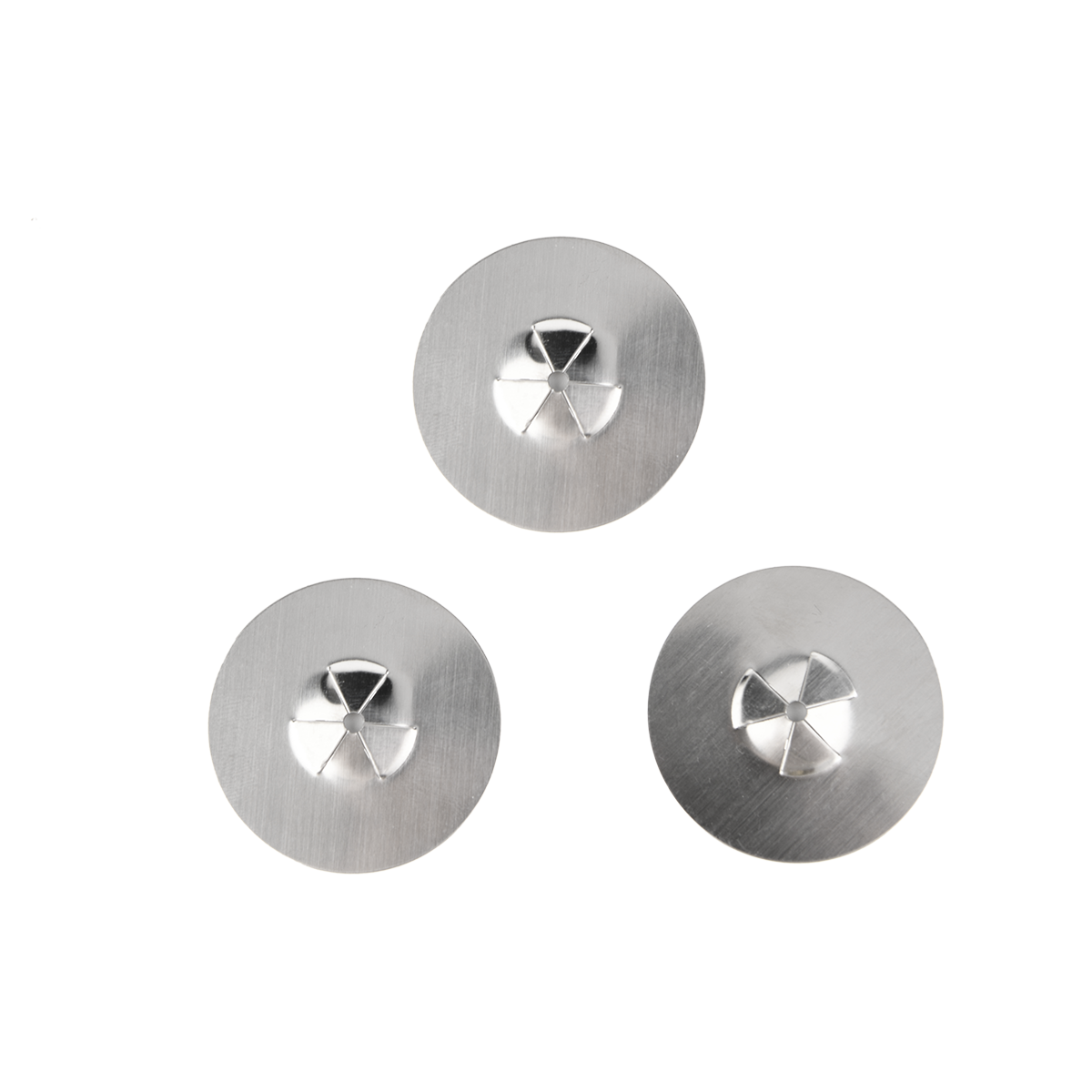

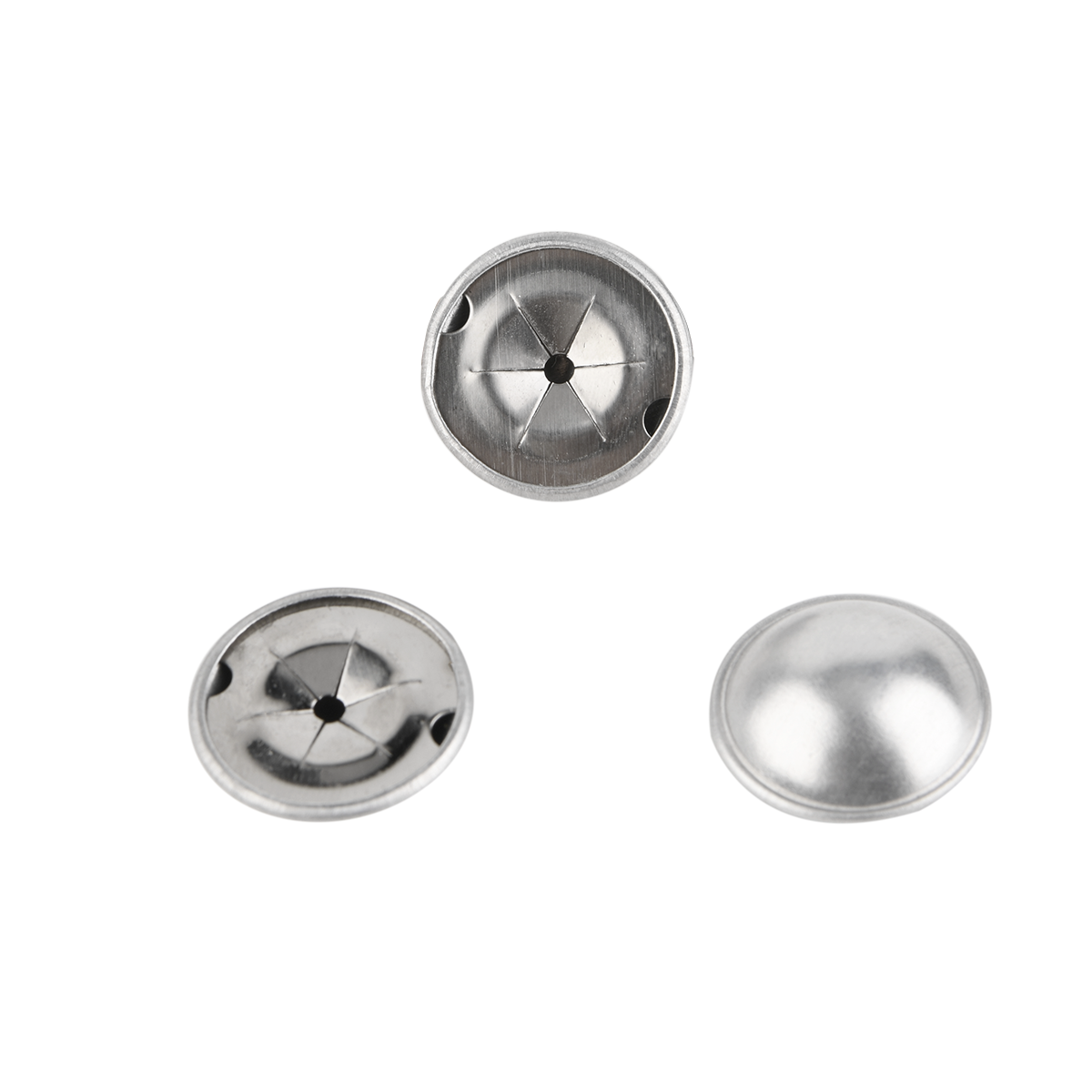

The design of insulation pins for metal is engineered to provide a secure hold on the insulation material while also being easy to install. These pins usually have a sharp point or tip that can easily penetrate the insulation and the metal substrate. The head of the pin is designed to distribute the load evenly and prevent the insulation from pulling away or sagging.

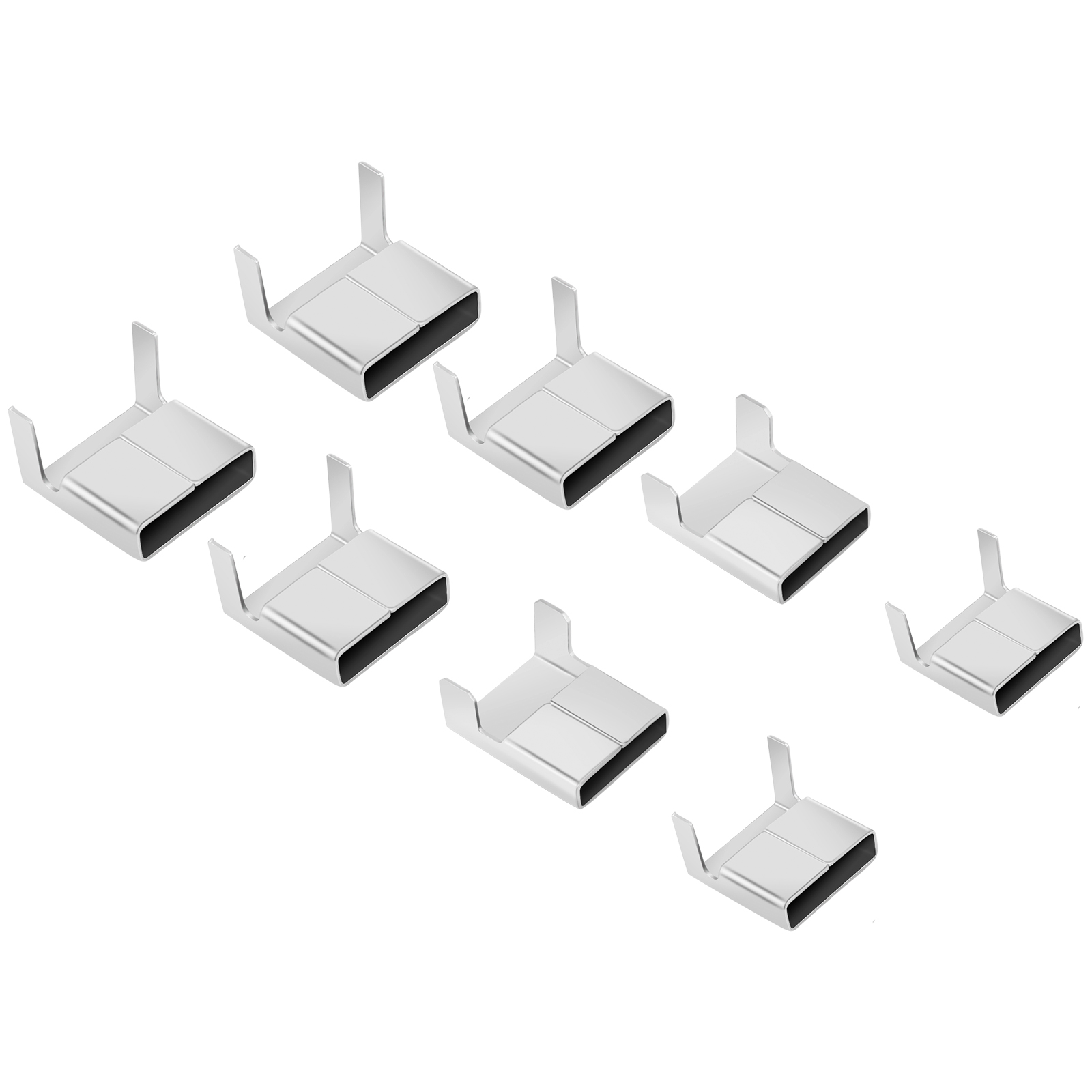

Some insulation pins for metal may also feature additional features such as a locking mechanism or a washer to enhance their holding power. These features can be particularly useful in applications where there is vibration or movement, ensuring that the insulation remains firmly in place.

Another important feature of insulation pins for metal is their resistance to corrosion. Since metal surfaces are often exposed to moisture, chemicals, and other corrosive elements, the pins need to be made of materials that can withstand these conditions without deteriorating. This helps to ensure the long-term performance and durability of the insulation system.

Applications:

Insulation pins for metal find wide applications in various industries and sectors. Some of the common areas where these pins are used include:

Industrial Facilities: In industrial settings, insulation pins for metal are used to insulate pipes, ducts, tanks, and other metal equipment. This helps to reduce heat loss or gain, improve energy efficiency, and protect workers from extreme temperatures. Insulation pins for metal are also used in fireproofing applications to prevent the spread of fire and protect valuable assets.

Construction: In the construction industry, insulation pins for metal are used to insulate metal framing, roofs, and walls. They help to improve the thermal performance of buildings, reduce noise transmission, and enhance indoor comfort. Insulation pins for metal are also used in exterior cladding systems to provide a stable and secure attachment for insulation materials.

Automotive Industry: The automotive industry uses insulation pins for metal to insulate engine compartments, exhaust systems, and other metal parts. This helps to reduce noise and heat transfer, improving the driving experience and protecting sensitive components. Insulation pins for metal are also used in the manufacturing of vehicles to ensure proper insulation and soundproofing.

Aerospace Industry: In the aerospace industry, insulation pins for metal are used to insulate aircraft components, such as fuel tanks, engines, and fuselages. They help to reduce heat transfer and noise, improving the performance and safety of aircraft. Insulation pins for metal are also used in space applications to protect sensitive equipment from extreme temperatures and radiation.

Benefits:

Using insulation pins for metal offers several benefits, including:

Effective Insulation: Insulation pins for metal provide a reliable and secure way to attach insulation materials to metal surfaces, ensuring effective thermal and acoustic insulation. This helps to reduce energy consumption, improve indoor comfort, and protect equipment and structures from damage caused by extreme temperatures.

Durability: These pins are made of materials that are designed to withstand harsh environments and long-term use. They are resistant to corrosion, wear, and tear, ensuring the longevity of the insulation system. Insulation pins for metal can also withstand vibration and movement, making them suitable for applications where there is mechanical stress.

Easy Installation: Insulation pins for metal are easy to install, requiring only basic tools and techniques. They can be quickly and easily inserted into the insulation and the metal substrate, providing a fast and efficient installation process. This saves time and labor costs compared to other insulation attachment methods.

Versatility: Insulation pins for metal are available in a variety of sizes, shapes, and materials, making them suitable for different applications and insulation requirements. They can be used with different types of insulation materials, including fiberglass, foam, mineral wool, and more. This provides flexibility and versatility in designing insulation systems.

Installation Methods:

The installation of insulation pins for metal typically involves the following steps:

Surface Preparation: Before installing insulation pins for metal, the metal surface should be cleaned and prepared. This may involve removing any dirt, grease, or rust from the surface to ensure a good bond between the pin and the metal. In some cases, a primer or adhesive may be applied to enhance the adhesion.

Measuring and Marking: Measure the insulation thickness and mark the locations where the pins will be installed. This ensures that the pins are evenly spaced and provide proper support for the insulation.

Insertion of Pins: Using a hammer or a power tool, insert the insulation pins into the metal substrate at the marked locations. Make sure that the pins are inserted straight and perpendicular to the surface to ensure a secure hold. If using a power tool, follow the manufacturer's instructions for proper operation and safety.

Attachment of Insulation: Once the pins are in place, attach the insulation material to the pins. This can be done by using adhesives, staples, or other fastening methods depending on the type of insulation and the installation requirements. Make sure that the insulation is tightly secured to the pins to prevent sagging or movement.

Finishing: After attaching the insulation, check for any gaps or voids and fill them with additional insulation or sealant if necessary. Finish the installation by trimming any excess insulation and ensuring a clean and professional appearance.

Conclusion:

Insulation pins for metal are an essential component in achieving effective insulation in applications where metal surfaces are involved. With their specific design, features, applications, benefits, and installation methods, these pins provide a reliable and durable solution for thermal and acoustic insulation. Whether in industrial facilities, construction projects, the automotive industry, or aerospace applications, insulation pins for metal play a crucial role in improving energy efficiency, indoor comfort, and the longevity of equipment and structures. By choosing the right insulation pins for metal and following proper installation procedures, you can ensure a successful insulation installation that meets your specific needs.