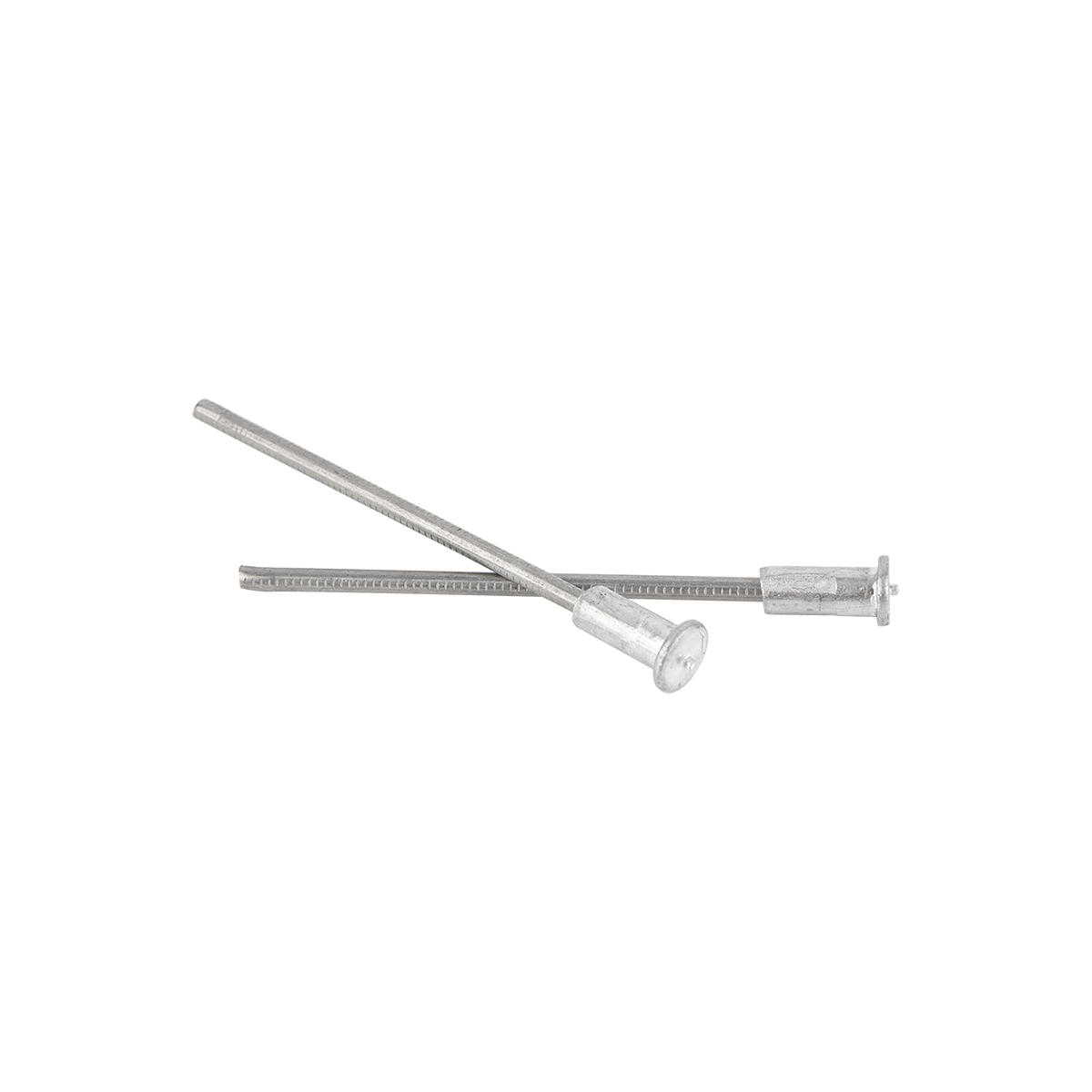

Insulation Pins and Self-Locking Washers

Insulation pins and self-locking washers are essential components in many insulation installation projects. These small but crucial elements play a significant role in ensuring the stability and effectiveness of insulation materials. In this in-depth exploration, we will examine insulation pins and self-locking washers in detail, covering their characteristics, functions, applications, and more.

Contact

Product Detail

I. Introduction to Insulation Pins and Self-Locking Washers

Insulation pins are designed to hold insulation materials in place by penetrating through the insulation and into the underlying substrate. They provide a secure attachment point that helps prevent the insulation from sagging, shifting, or being dislodged. Self-locking washers, on the other hand, are used in conjunction with insulation pins to enhance their holding power and prevent loosening over time.

The combination of insulation pins and self-locking washers offers a reliable and durable solution for insulation installation. By working together, these components ensure that the insulation remains firmly in place, providing effective thermal and acoustic insulation.

II. Characteristics of Insulation Pins

A. Material Options

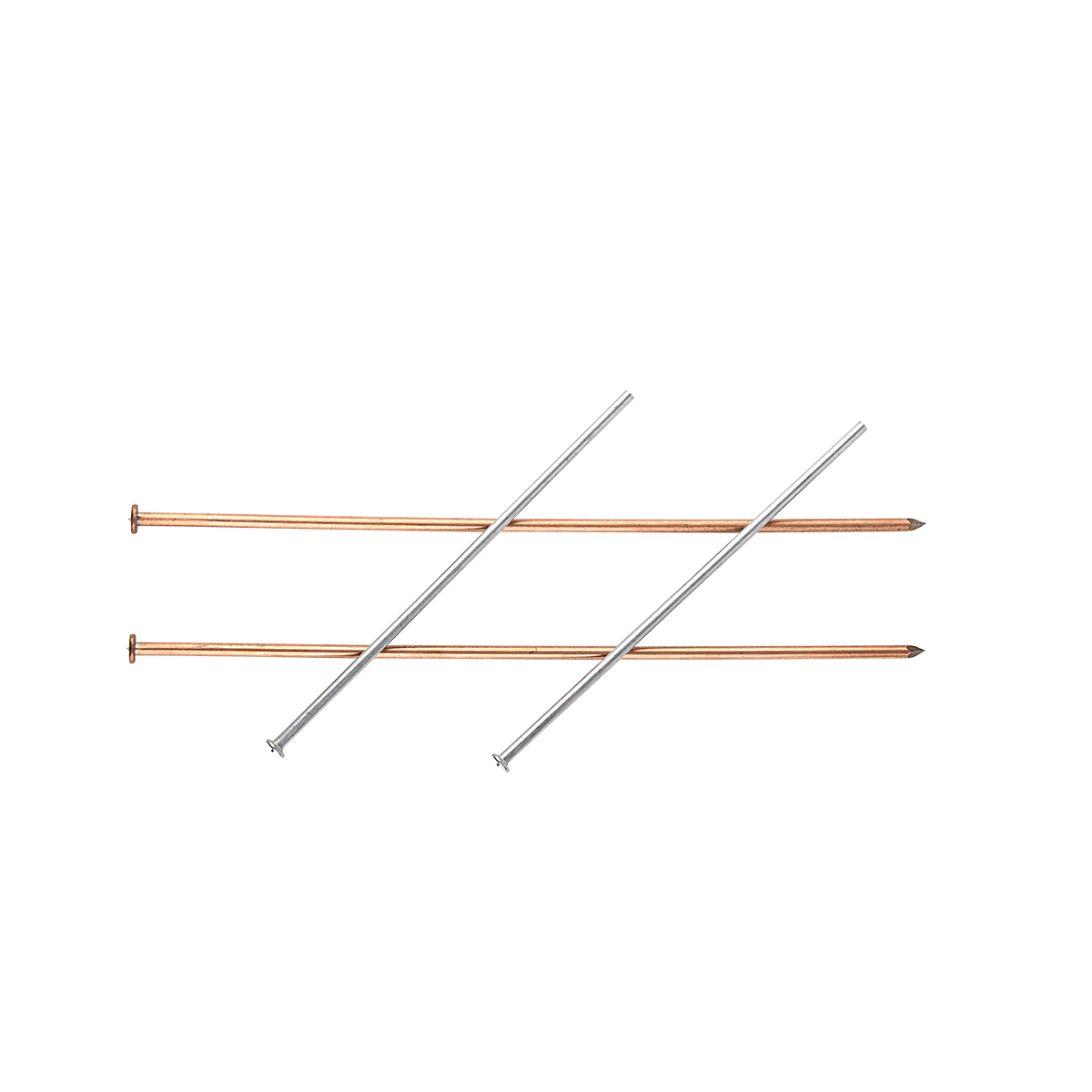

Stainless Steel: Stainless steel insulation pins are highly durable and resistant to corrosion. They can withstand harsh environmental conditions and are suitable for use in both indoor and outdoor applications. Stainless steel pins are also strong and can support heavy insulation materials, making them ideal for large-scale projects.

Galvanized Steel: Galvanized steel insulation pins offer good strength and corrosion resistance. They are coated with a layer of zinc, which provides protection against rust and corrosion. Galvanized steel pins are a cost-effective option and are commonly used in many insulation installations.

Plastic: Plastic insulation pins are lightweight and easy to install. They are available in different colors, which can be useful for aesthetic purposes or for identifying different types of insulation. Plastic pins are also resistant to moisture and chemicals, making them suitable for use in damp or corrosive environments.

B. Design Features

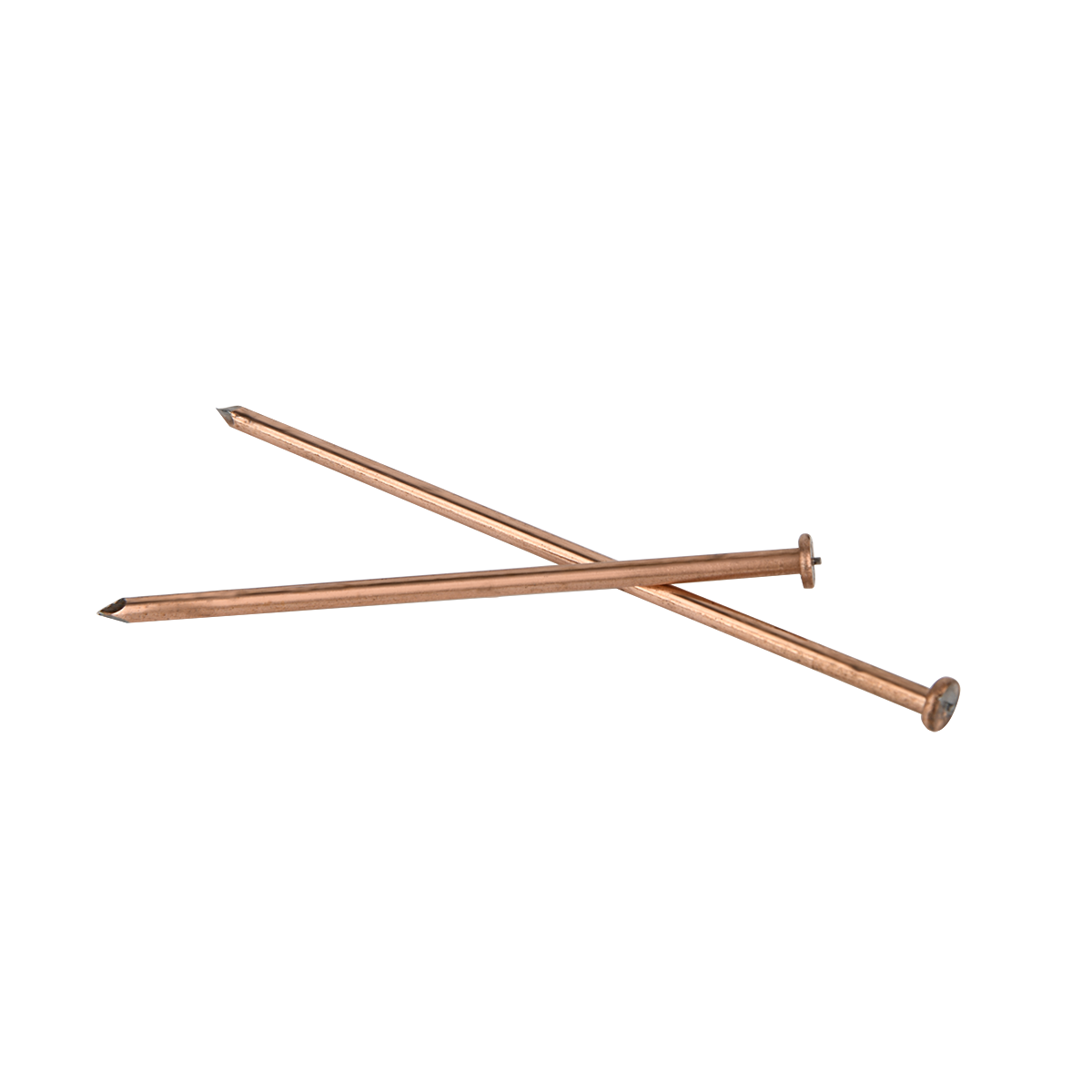

Sharp Point: The sharp point of an insulation pin allows it to easily penetrate through the insulation material and into the substrate. This ensures a secure attachment and minimizes the risk of damage to the insulation during installation.

Head Design: The head of an insulation pin is designed to hold the insulation in place and prevent it from slipping off. Some pins have a flat head, while others may have a domed or rounded head for added stability.

Length and Diameter: Insulation pins come in a variety of lengths and diameters to accommodate different insulation thicknesses and installation requirements. Longer pins may be needed for thicker insulation or when attaching insulation to deeper substrates. The diameter of the pin should be appropriate for the insulation material and the substrate to ensure a secure fit.

C. Insulation Compatibility

Insulation pins are designed to be compatible with a wide range of insulation materials, including fiberglass, mineral wool, foam board, and more. They can be used with different types of insulation depending on the specific application and requirements.

III. Characteristics of Self-Locking Washers

A. Material Options

Stainless Steel: Stainless steel self-locking washers are highly durable and resistant to corrosion. They offer excellent strength and can withstand high levels of stress. Stainless steel washers are suitable for use in harsh environments and are often preferred for long-term installations.

Galvanized Steel: Galvanized steel self-locking washers provide good corrosion resistance and strength. They are a cost-effective option and are commonly used in many applications. Galvanized steel washers are suitable for both indoor and outdoor use.

Nylon: Nylon self-locking washers are lightweight and resistant to chemicals and moisture. They are often used in applications where corrosion resistance is important or where a non-metallic option is preferred. Nylon washers are available in different colors and can be used for aesthetic purposes.

B. Design Features

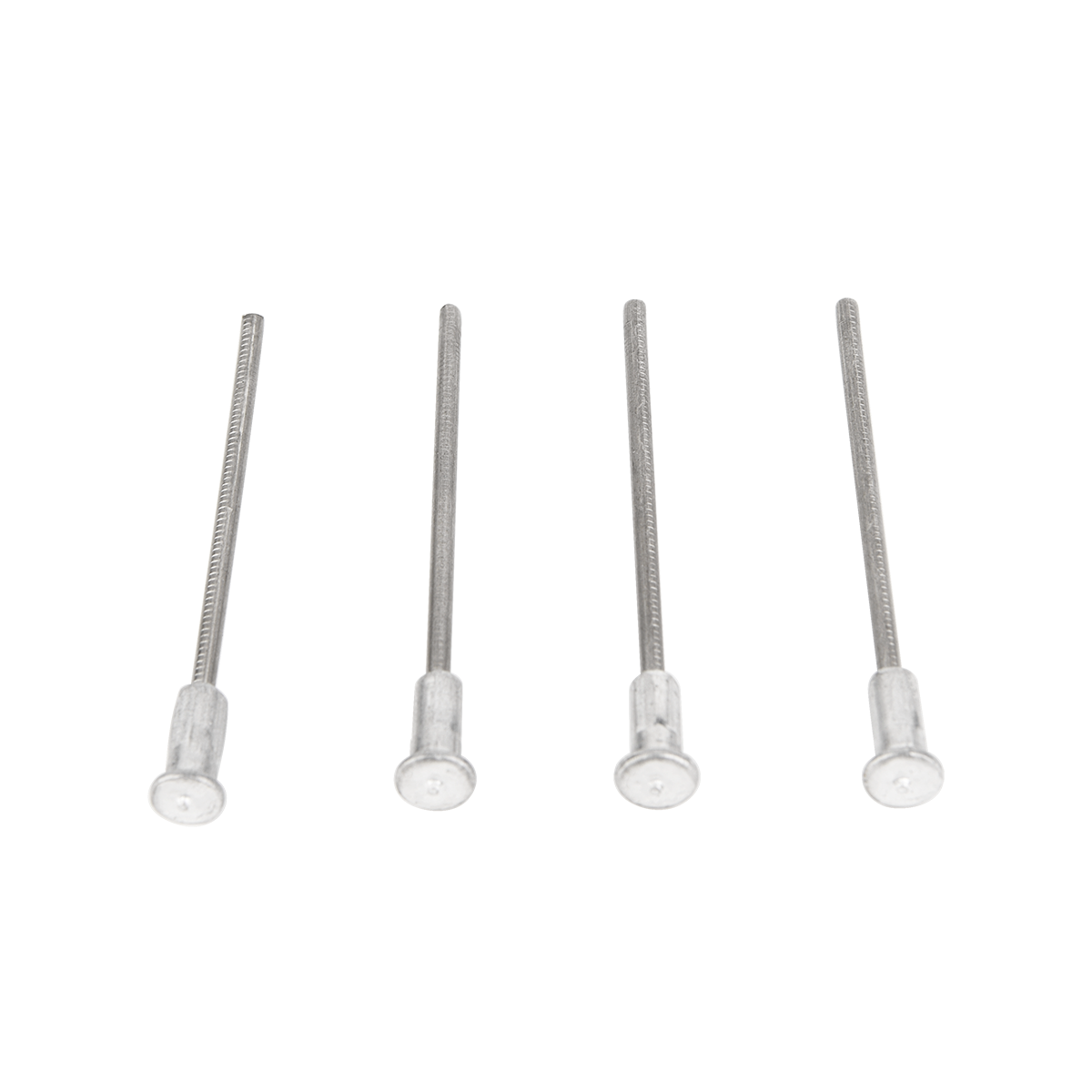

Locking Mechanism: Self-locking washers have a unique design that provides a locking function. This mechanism helps prevent the nut or bolt from loosening over time, ensuring a secure connection. The locking mechanism can be in the form of serrations, teeth, or other features that grip the mating surface and prevent movement.

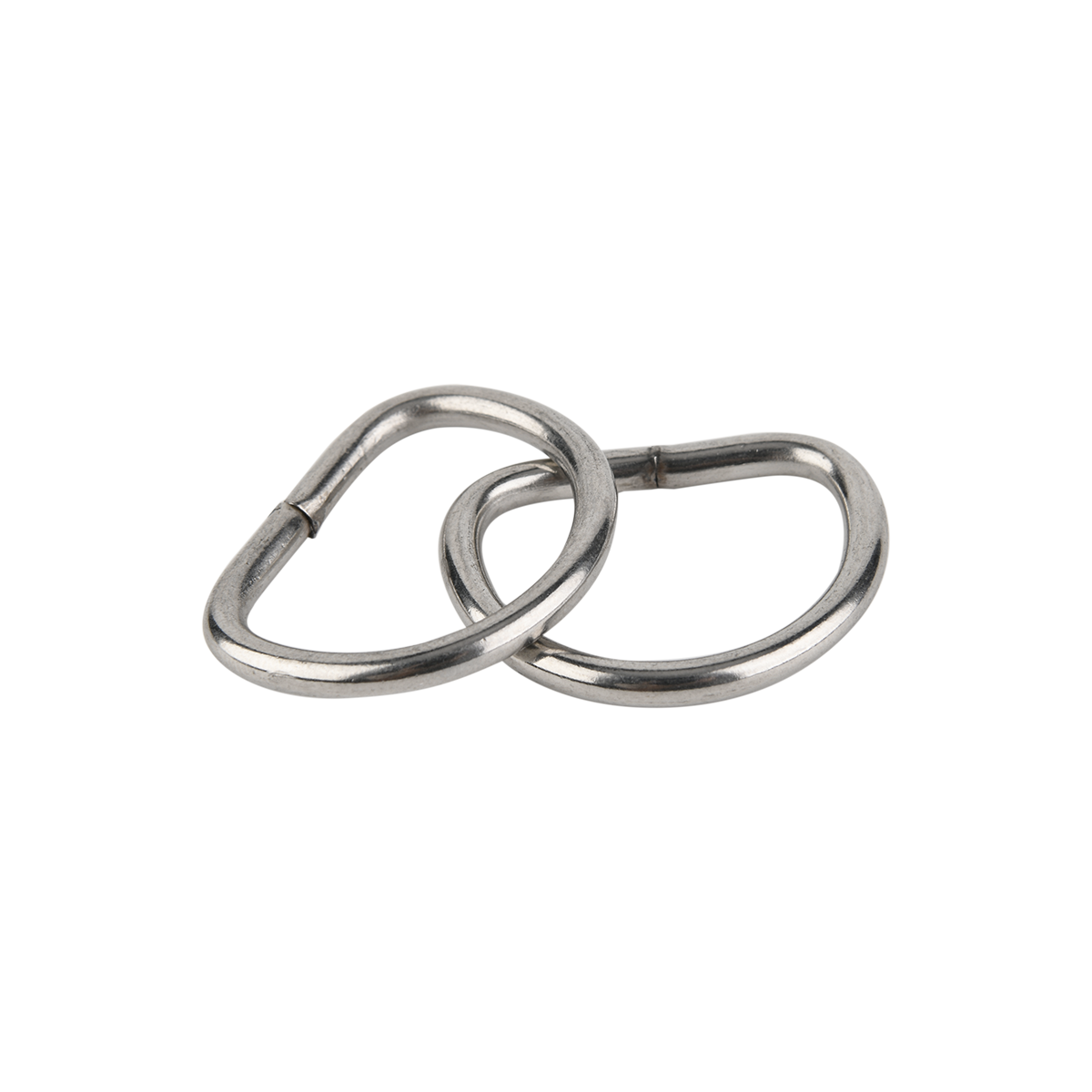

Washer Shape: Self-locking washers come in different shapes, such as flat washers, conical washers, or split washers. The shape of the washer is chosen based on the specific application and requirements. Flat washers are the most common type and are suitable for most applications. Conical washers are used when a tapered surface is required, while split washers are used for applications where vibration or movement is a concern.

Size and Thickness: Self-locking washers are available in a range of sizes and thicknesses to accommodate different bolt or nut sizes and installation requirements. The size and thickness of the washer should be selected based on the load and stress requirements of the application.

IV. Functions of Insulation Pins and Self-Locking Washers

A. Securing Insulation

The primary function of insulation pins is to hold insulation materials in place. By penetrating through the insulation and into the substrate, the pins create a mechanical bond that resists the forces of gravity, wind, and vibration. Self-locking washers enhance this holding power by providing additional resistance against loosening. Together, they ensure that the insulation remains firmly attached and provides effective thermal and acoustic insulation.

B. Preventing Air Leakage

In addition to securing the insulation, insulation pins and self-locking washers can also help prevent air leakage. When the insulation is properly installed and secured with pins and washers, there are fewer gaps and openings through which air can pass. This helps improve the energy efficiency of a building or structure by reducing heat loss or gain through air infiltration.

C. Enhancing Durability

Insulation pins and self-locking washers can enhance the durability of the insulation system. By providing a secure attachment point, they help distribute the load evenly across the insulation, reducing stress and wear. This can extend the lifespan of the insulation and reduce the need for frequent maintenance or replacement.

D. Facilitating Installation

Insulation pins and self-locking washers can make the installation process easier and more efficient. They provide a quick and convenient way to secure the insulation, eliminating the need for complex fastening systems or adhesives. This can save time and labor costs, especially in large-scale installations.

V. Applications of Insulation Pins and Self-Locking Washers

A. Residential Construction

In residential construction, insulation pins and self-locking washers are commonly used to install insulation in attics, walls, and floors. They help ensure that the insulation remains in place and provides effective thermal and acoustic insulation, reducing energy consumption and improving indoor comfort.

For attic insulation, the pins can be used to secure blown-in insulation or batt insulation to the ceiling joists. In wall insulation applications, the pins can be used to attach insulation boards to the studs or sheathing. And for floor insulation, the pins can be used to hold insulation mats or boards in place.

B. Commercial Construction

In commercial construction, insulation pins and self-locking washers are used in a variety of applications, including office buildings, hospitals, schools, and retail stores. They are often used to install insulation in ceilings, walls, and ductwork, helping to improve energy efficiency and reduce noise levels.

For example, in a commercial office building, the pins can be used to secure insulation to the metal decking of the ceiling. In a hospital, the pins can be used to install insulation around ductwork to reduce noise transmission. And in a school, the pins can be used to attach insulation boards to the walls to improve thermal comfort.

C. Industrial Construction

In industrial construction, insulation pins and self-locking washers are used to insulate pipes, ducts, vessels, and other equipment. They help maintain process temperatures and reduce heat loss or gain, improving the efficiency of industrial processes and reducing energy consumption.

For example, in a chemical plant, the pins can be used to install insulation around pipes and vessels to prevent heat loss and ensure the safety of workers. In a food processing facility, the pins can be used to insulate ductwork to maintain air quality and prevent condensation.

D. HVAC Systems

Insulation pins and self-locking washers are an essential component in the installation of HVAC (heating, ventilation, and air conditioning) systems. They are used to secure insulation around ducts and pipes, helping to prevent heat loss or gain and improve the efficiency of the HVAC system.

For example, in an HVAC ductwork installation, the pins can be used to attach insulation blankets or boards to the ducts. The self-locking washers provide additional holding power to ensure that the insulation remains in place even under the vibration and movement of the HVAC system.

E. Other Applications

Insulation pins and self-locking washers can also be used in a variety of other applications, such as marine construction, aerospace engineering, and automotive manufacturing. They are often used to install insulation in areas where space is limited or where traditional fastening methods are not feasible.

For example, in marine construction, the pins can be used to install insulation in ship hulls or engine rooms. In aerospace engineering, the pins can be used to insulate aircraft cabins or engine nacelles. And in automotive manufacturing, the pins can be used to install insulation in vehicle interiors to reduce noise and improve thermal comfort.

VI. Choosing the Right Insulation Pins and Self-Locking Washers

A. Consideration of Insulation Type

When choosing insulation pins and self-locking washers, it is important to consider the type of insulation being used. Different insulation materials have different densities, thicknesses, and installation requirements, so it is important to select pins and washers that are compatible with the specific insulation being installed.

For example, fiberglass insulation may require pins with a different diameter or length than mineral wool insulation. Blown-in insulation may require pins with a special design to ensure proper penetration and holding power. The self-locking washers should also be selected based on the size and type of pin being used.

B. Load Capacity

The load capacity of the insulation pins and self-locking washers is another important consideration. Depending on the application, the insulation may be subjected to different loads, such as gravity, wind pressure, or vibration. It is important to select pins and washers that have a sufficient load capacity to handle the expected loads and ensure a secure installation.

For example, in areas where the insulation may be subjected to high winds or heavy loads, it may be necessary to use pins with a larger diameter or stronger material and self-locking washers with a higher locking force.

C. Environmental Conditions

The environmental conditions in which the insulation pins and self-locking washers will be installed should also be considered. If the pins and washers will be exposed to moisture, chemicals, or extreme temperatures, it is important to select materials that are resistant to these conditions.

For example, in a marine environment, stainless steel pins and washers may be a better choice than galvanized steel due to their superior corrosion resistance. In an industrial setting where the insulation may be exposed to chemicals, pins and washers made from a chemical-resistant material may be required.

D. Installation Method

The installation method for the insulation pins and self-locking washers will also affect the selection process. Different installation methods may require different types of pins and washers or installation tools.

For example, if the insulation will be installed using a pneumatic gun, it is important to select pins and washers that are compatible with the gun and have the appropriate length and diameter for the application. If the insulation will be installed manually, pins and washers with a sharp point and easy-to-use head may be preferred.

E. Cost

Finally, cost is always a consideration when choosing insulation pins and self-locking washers. While it is important to select high-quality components that will provide a reliable installation, it is also important to consider the cost and ensure that it fits within the budget for the project.

Insulation pins and self-locking washers are available in a range of prices, depending on the material, size, and features. It is possible to find cost-effective options that still meet the requirements of the project without sacrificing quality.

VII. Installation Process of Insulation Pins and Self-Locking Washers

A. Preparation

Before installing insulation pins and self-locking washers, it is important to prepare the installation area. This may involve cleaning the substrate to remove any dirt, debris, or loose materials. The insulation should also be cut to the appropriate size and shape to fit the area being insulated.

If the substrate is metal, it may be necessary to drill pilot holes to ensure proper penetration of the pins. For wood substrates, the pins can usually be driven directly into the surface without the need for pilot holes.

B. Insertion of Pins

To install the insulation pins, start by positioning the insulation material on the substrate. Then, using a hammer or other suitable tool, drive the pin through the insulation and into the substrate. Make sure to insert the pin at a perpendicular angle to ensure a secure attachment.

The depth of insertion should be sufficient to provide a strong hold, but not so deep that it damages the substrate or compromises the integrity of the insulation. Refer to the manufacturer's instructions for specific recommendations on insertion depth.

C. Installation of Self-Locking Washers

Once the pins are inserted, place a self-locking washer over the pin head. The washer should be positioned so that the locking mechanism engages with the pin head and provides additional holding power. Tighten the nut or bolt if necessary to secure the washer in place.

D. Spacing and Layout

The spacing and layout of the insulation pins and self-locking washers will depend on the type and thickness of the insulation, as well as the installation requirements. Generally, pins and washers should be spaced evenly across the surface of the insulation to ensure a uniform distribution of load.

Refer to the manufacturer's instructions or consult a professional for specific recommendations on spacing and layout. In some cases, it may be necessary to use additional pins or washers or install them in a specific pattern to ensure a secure installation.

E. Finishing Touches

Once the pins and washers are installed, check to make sure that the insulation is firmly in place and there are no gaps or loose areas. If necessary, add additional pins or washers or adjust the spacing to ensure a proper installation.

Finally, finish the installation by covering the pins and washers with a suitable finishing material, such as tape or caulking, to protect them from moisture and other environmental factors. This can also help improve the aesthetic appearance of the installation.

VIII. Maintenance and Care of Insulation Pins and Self-Locking Washers

A. Inspection

Regular inspection of insulation pins and self-locking washers is important to ensure their continued effectiveness. Check for any signs of damage, such as bent or broken pins, loose washers, or corrosion. If any issues are found, they should be addressed promptly to prevent further damage or loss of insulation performance.

Inspect the pins and washers at least once a year, or more frequently if the installation is subjected to harsh environmental conditions or heavy loads. During the inspection, also check for any signs of wear or deterioration of the insulation material and take appropriate action if necessary.

B. Cleaning

If the insulation pins and self-locking washers become dirty or contaminated, they can be cleaned using a mild detergent and water. Avoid using harsh chemicals or abrasives, as these can damage the pins and washers or the insulation material.

After cleaning, make sure to dry the pins and washers thoroughly before reinstalling the insulation. This can help prevent corrosion and ensure the pins and washers remain in good condition.

C. Replacement

If insulation pins or self-locking washers become damaged or worn out, they should be replaced promptly. This will ensure that the insulation remains securely in place and continues to provide the desired level of thermal and acoustic insulation.

When replacing pins and washers, make sure to use the same type and size as the original components to ensure a proper fit. Follow the installation instructions carefully to ensure a secure installation.

IX. Conclusion

Insulation pins and self-locking washers are essential components in many insulation installation projects. They provide a reliable and durable solution for securing insulation materials and ensuring effective thermal and acoustic insulation. By understanding the characteristics, functions, applications, and selection criteria for insulation pins and self-locking wash...