Insulation pins accessories

Insulation nail accessories are a series of auxiliary components used in conjunction with insulation nails to enhance the stability of insulation system installation and improve insulation effectiveness. Its main functions include:

Contact

Product Detail

1、 Definition and function of insulation nail accessories

Enhanced fixing effect: Insulation nails are used to fix insulation materials on the surfaces of building walls, roofs, pipelines, etc. However, relying solely on insulation nails may not fully guarantee the firm adhesion of insulation materials under various complex working conditions. Insulation nail accessories, such as gaskets, nuts, etc., work together with insulation nails to greatly enhance the fixing effect of insulation nails on insulation materials by increasing the contact area and providing fastening force, preventing insulation materials from falling off or shifting due to external forces (such as wind loads, vibrations, etc.).

Optimizing insulation performance: Some insulation nail accessories have special design or material characteristics that can reduce the conduction or loss of heat through the insulation nail parts, thereby optimizing the overall insulation performance of the insulation system. For example, gaskets made of insulation materials can reduce the transfer of heat from fixed points, avoid the formation of local thermal bridge effects, and make the insulation effect of the insulation system more uniform and efficient.

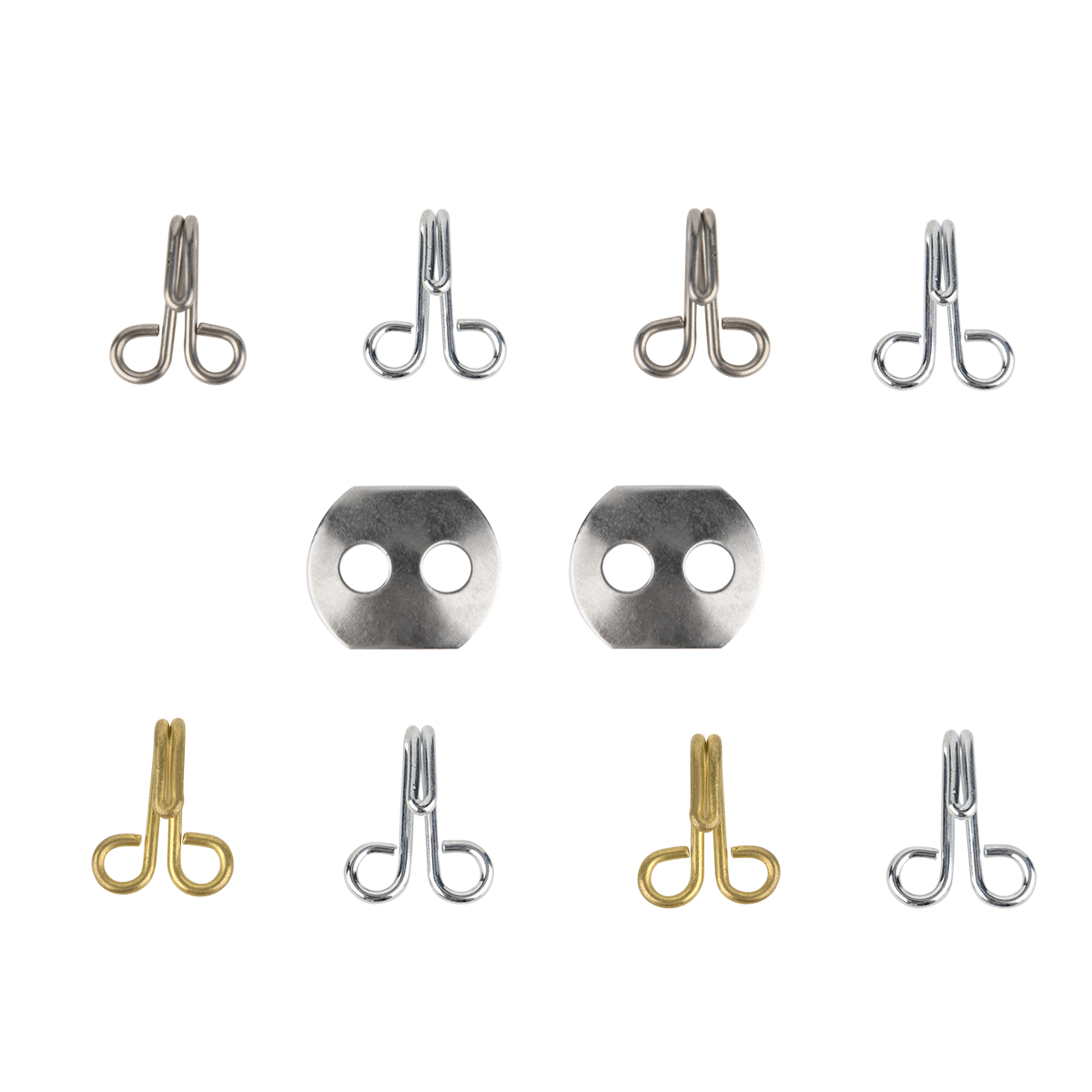

2、 Common types of insulation nail accessories

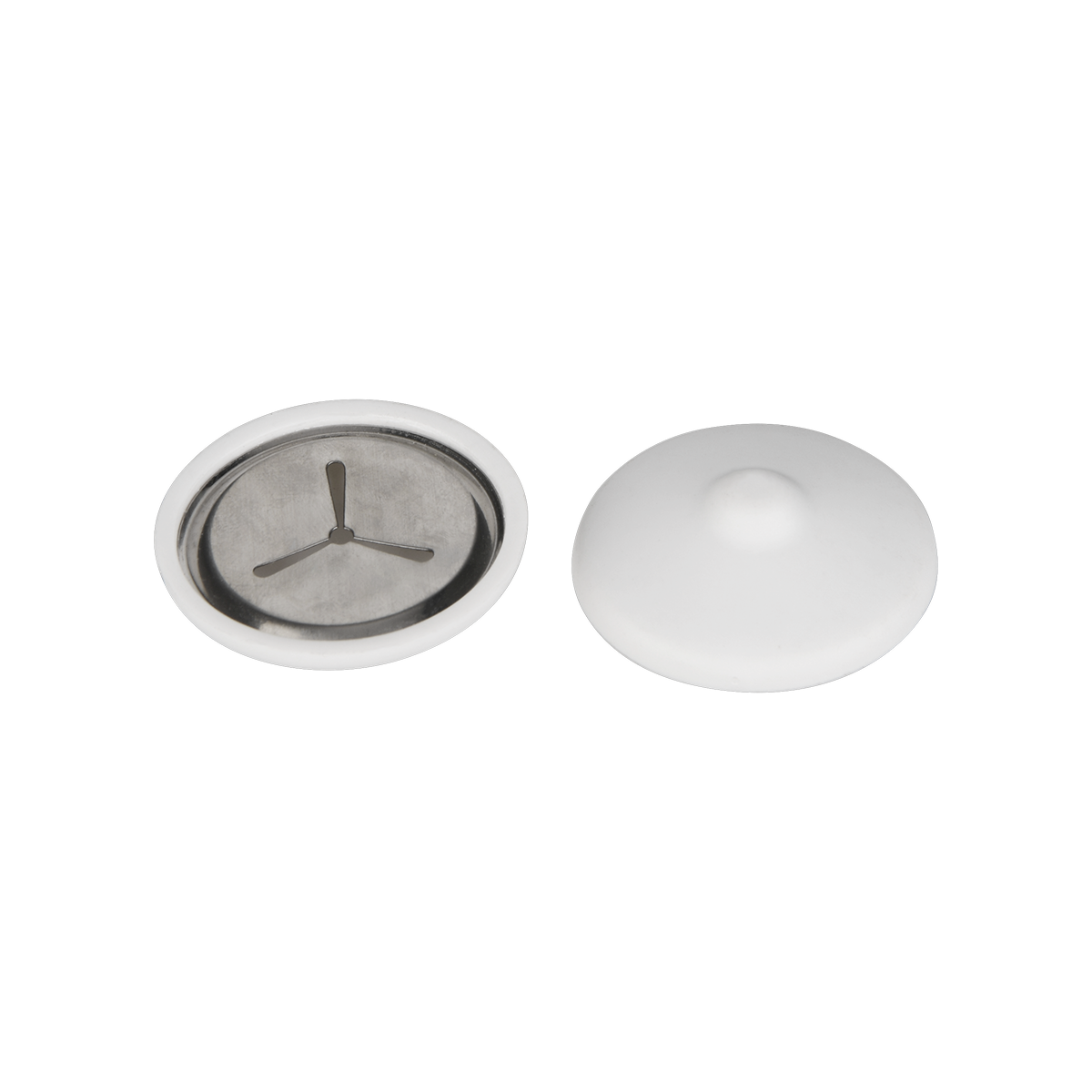

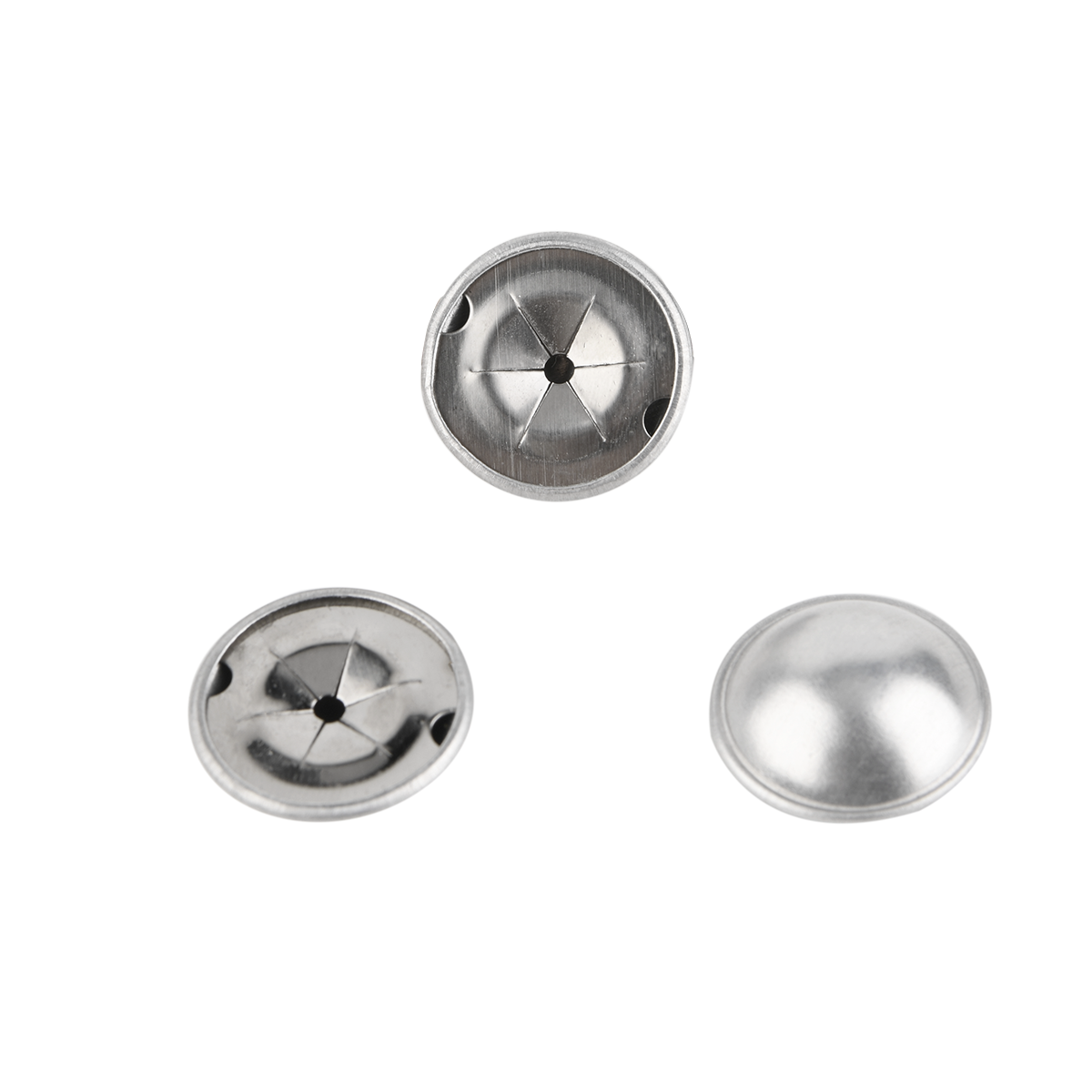

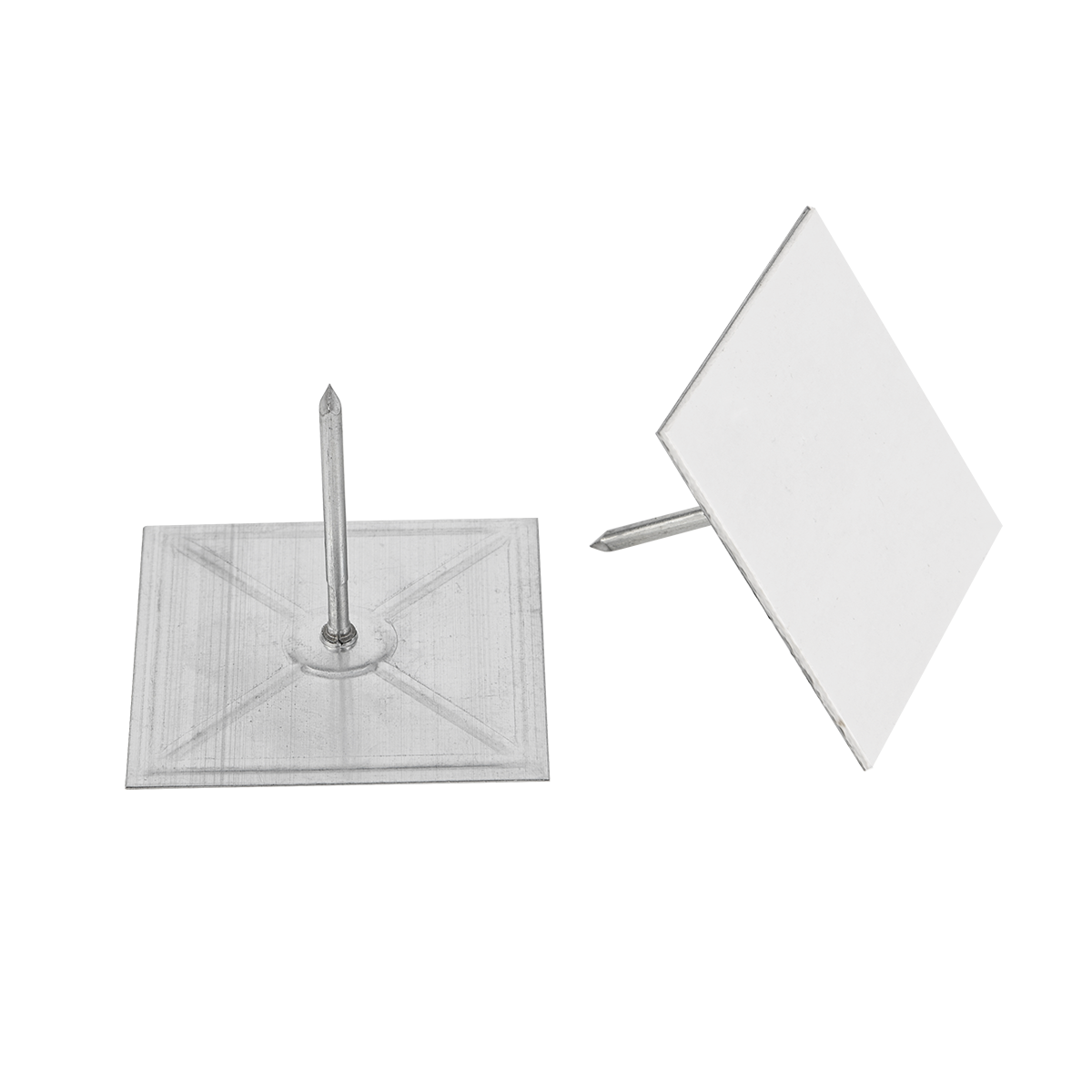

shim

Material: Common gasket materials include rubber, plastic, metal, etc. Rubber gaskets have good elasticity and flexibility, and can adapt to the unevenness of insulation materials and substrate surfaces, providing good sealing and buffering effects; Plastic gaskets usually have certain strength and corrosion resistance, and the cost is relatively low; Metal gaskets are generally made of stainless steel or galvanized materials, which have high strength and durability, and are suitable for occasions with high requirements for fixed strength.

Shape and size: The shape of the gasket includes circular, square, elliptical, etc. Its size should match the insulation nail to ensure complete coverage of the contact area between the insulation nail and the insulation material. For example, for insulation nails with smaller diameters, smaller sized circular washers can be used; For larger areas of insulation material fixation, it may be necessary to use larger square gaskets to provide more uniform support and fixing force.

Functional characteristics: The main function of the gasket is to disperse the pressure of the insulation nail on the insulation material, avoiding damage to the insulation material due to excessive local pressure. At the same time, the gasket can also increase the friction between the insulation nail and the insulation material, improving the stability of the fixation. In addition, some specially designed gaskets, such as those with anti slip patterns or concave convex structures, can further enhance the anti slip effect, ensuring that the insulation material will not slide due to slight external forces during long-term use.

Nut

Material and type: The material of nuts usually includes carbon steel, stainless steel, and alloy steel. Carbon steel nuts have lower cost and higher strength, but may rust easily in some corrosive environments; Stainless steel nuts have good corrosion resistance and are suitable for harsh environments such as humidity, acidity, and alkalinity; Alloy steel nuts have higher strength and special properties, which can meet some situations with extremely high requirements for tightening force and durability. According to the thread type, nuts can be divided into ordinary thread nuts (such as M6, M8 and other common specifications) and fine thread nuts. Fine thread nuts have a smaller pitch and are more tightly fastened, making them suitable for parts that are sensitive to vibration and loosening.

Working principle: The nut is matched with the screw of the insulation nail, and by rotating the nut, it moves on the screw to generate a fastening force, firmly fixing the insulation material on the surface of the base layer. The tightening degree of the nut needs to be adjusted reasonably according to the specific installation requirements and the characteristics of the insulation material. Too loose may cause the insulation material to be not firmly fixed, while too tight may damage the insulation material or cause deformation of the insulation nails. In the actual installation process, tools such as wrenches or screwdrivers are usually used to tighten the nuts to ensure the appropriate tightening force is achieved.

Application scenarios: Nuts are widely used in various insulation nail installation scenarios, whether it is in the insulation engineering of building walls, or in the insulation treatment of pipelines, equipment, etc., they are indispensable. For example, in the insulation of pipelines in industrial plants, due to the possible flow of high or low temperature media inside the pipelines, they may experience certain vibrations and thermal expansion and contraction. At this time, using appropriate nuts and insulation nails can effectively ensure the firm fixation of insulation materials and prevent the insulation effect from decreasing due to vibration or deformation.

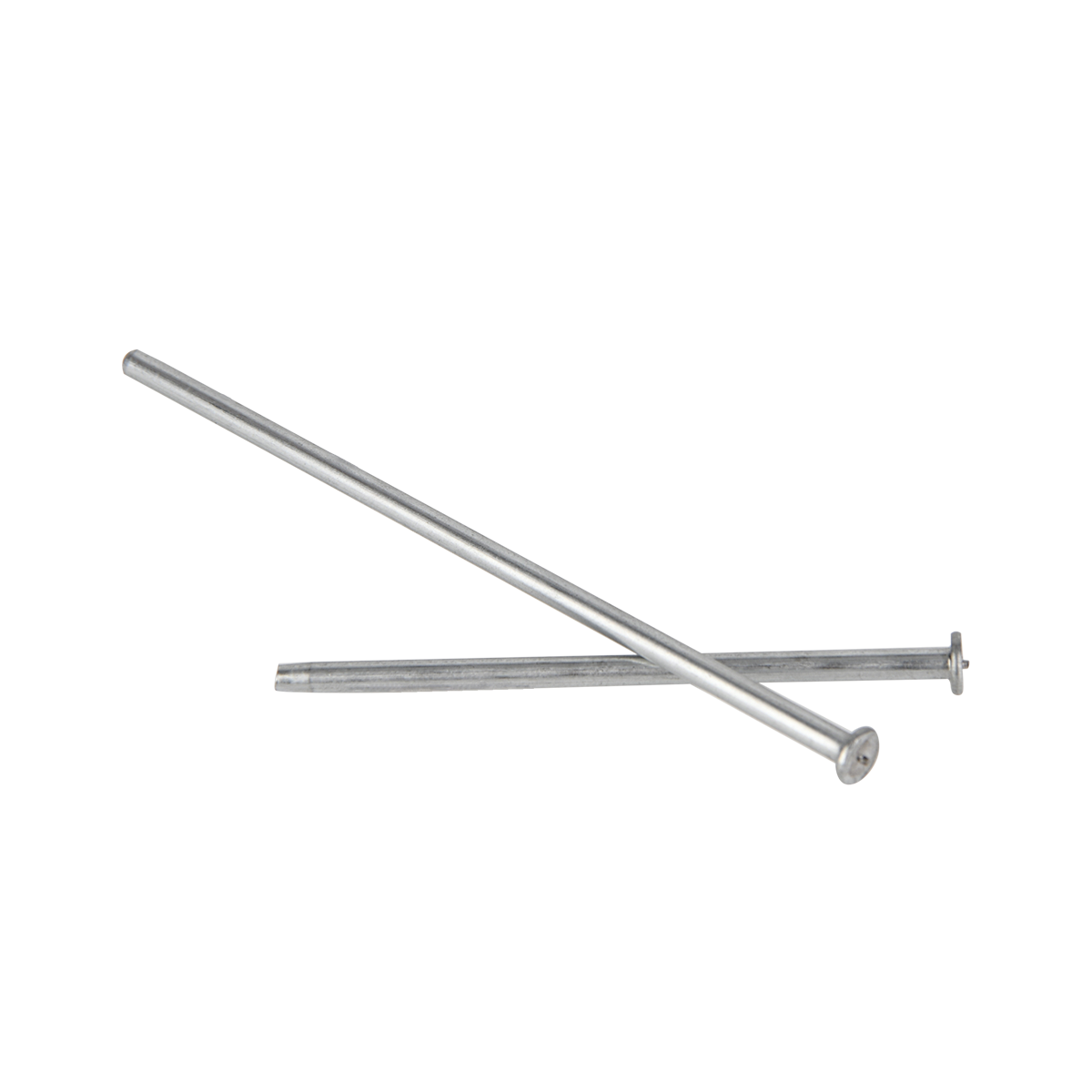

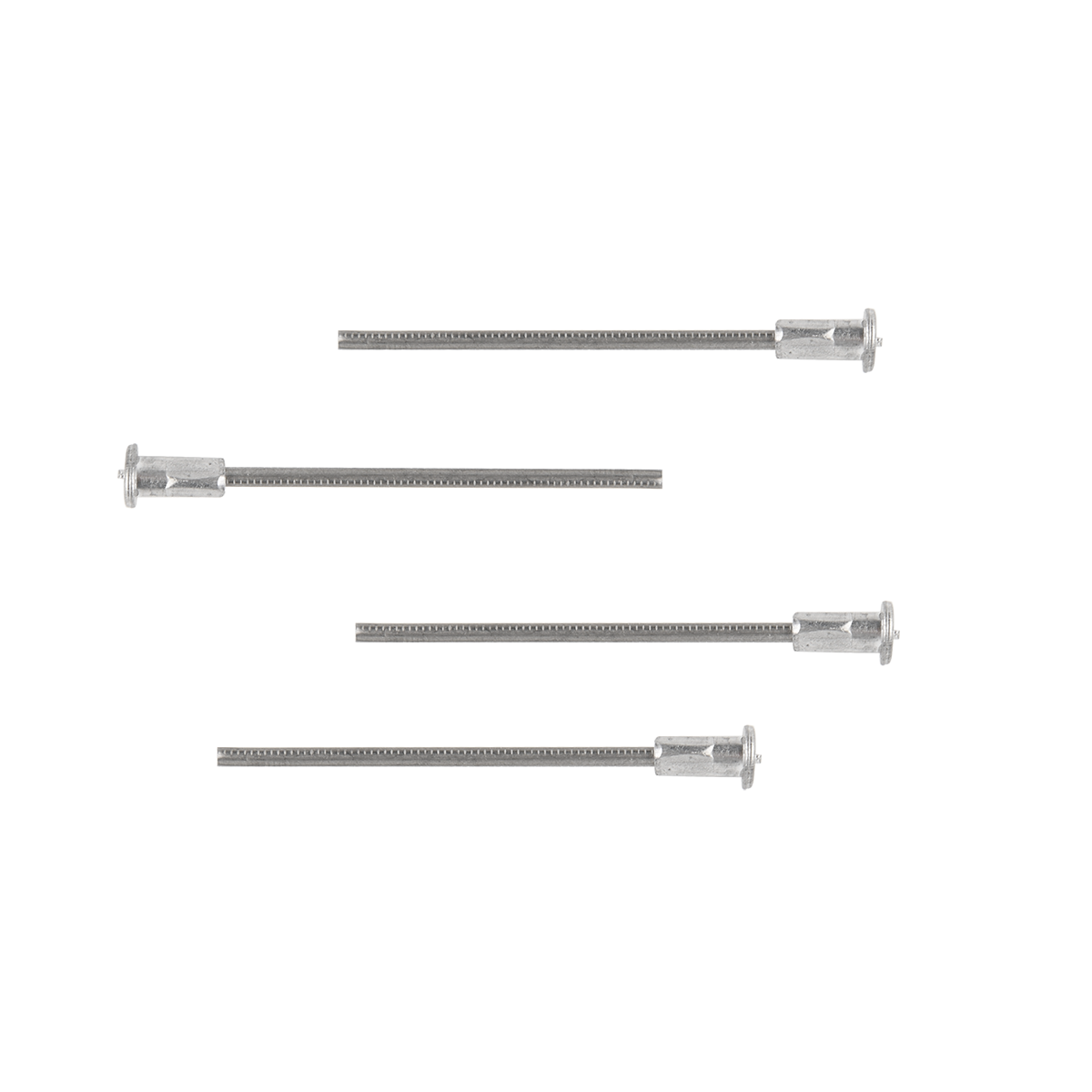

bushing

Material and Structure: The material of the casing generally includes plastic, rubber, and metal. Plastic casing has the advantages of light weight, low cost, corrosion resistance, and is easy to process and install; Rubber sleeves have good elasticity and sealing performance, and can adapt to small displacements of insulation nails during installation; Metal sleeves are usually made of galvanized steel pipes or stainless steel pipes, which have high strength and rigidity and can be used in situations with high protection requirements or the need to withstand large external forces. The structural forms of casing are diverse, commonly including circular straight pipe shape, wing edge shape (which can increase the contact area and friction with insulation materials), variable diameter shape (suitable for insulation nails or pipes of different diameters), etc.

Function and purpose: The main function of the sleeve is to protect the insulation nails, prevent them from being directly exposed to the external environment, and avoid damage such as corrosion, wear, or collision. At the same time, the casing can also improve the overall aesthetics of the insulation system to a certain extent. During the installation process, the sleeve is first placed on the insulation nail, then the insulation nail is fixed on the surface of the base layer, and finally the insulation material is installed outside the sleeve. For example, in the construction of building exterior wall insulation, the use of sleeves can protect insulation nails from erosion by rainwater, ultraviolet rays, etc., extend the service life of insulation nails, and ensure the long-term stability of the insulation system.

Other accessories

Glue: Glue is used to enhance the adhesion between insulation nails and insulation materials or substrate surfaces in some special situations. For example, when the surface of the base layer is relatively smooth and the insulation nails are difficult to directly fix firmly, an appropriate amount of glue can be applied to the surface of the base layer first, and then the insulation nails can be installed to better bond the insulation nails with the base layer. In addition, glue can also be used to bond insulation materials at the joints or edges to improve the overall integrity and sealing of the insulation materials. Common adhesives include epoxy resin adhesive, polyurethane adhesive, etc. They have the characteristics of high bonding strength, good water resistance, and aging resistance.

Labels or labels: Although labels or labels themselves do not directly participate in the fixing and insulation functions of insulation systems, they are of great significance for the construction management and quality traceability of insulation projects. Labels or labels can record information such as the model, specifications, production batch, installation location, etc. of insulation nail accessories, making it convenient for construction personnel to identify and classify them during the installation process, ensuring the use of correct accessories. At the same time, in the later maintenance and repair process, this information also helps to quickly locate the problem area and improve maintenance efficiency.

3、 Key points for selecting and using insulation nail accessories

Select appropriate accessories based on insulation materials and substrate types

Characteristics of thermal insulation materials: different types of thermal insulation materials, such as polystyrene foam board, rock wool board, glass fiber cotton, etc., have different materials, density, thickness and other characteristics, and the requirements for insulation nail accessories will also be different. For example, for the thermal insulation materials with soft texture, such as polystyrene foam board, large area of gaskets should be selected to avoid the penetration of insulation nails into the thermal insulation materials; For rock wool boards with higher density and strength, smaller size gaskets can be used, but it is necessary to ensure that the tightening force of the nuts is sufficient to prevent the insulation material from loosening.

Surface condition of the base layer: The material (such as concrete, brick wall, steel structure, etc.), flatness, roughness, etc. of the base layer surface can also affect the selection of insulation nail accessories. For the surface of the base layer with poor flatness, it is necessary to choose gaskets with certain elasticity and adaptability to compensate for the unevenness of the base layer; For smooth base surfaces, such as steel structure surfaces, special adhesives or accessories with anti slip structures may be required to increase bonding and friction.

Ensure that the quality and performance of the accessories meet the requirements

Quality standards: When selecting insulation nail accessories, it should be ensured that they comply with relevant national or industry quality standards. For example, the material of the gasket should meet the corresponding environmental requirements and must not contain harmful substances; The strength grade of the nut should meet the design requirements, and the thread accuracy should comply with the standard regulations. The quality of accessories can be verified by checking the product's quality inspection report, certification certificate, and other methods.

Performance testing: For some key performance indicators, such as the compression deformation rate of gaskets, the tightening force of nuts, and the corrosion resistance of sleeves, suppliers can be required to provide corresponding performance testing reports or conduct on-site sampling tests. For example, compression testing can be used to test the degree of deformation of gaskets under a certain pressure, to ensure that they can effectively disperse pressure during use; Verify through tightening force testing whether the nut can provide sufficient tightening force to ensure the fixing effect of the insulation material.

Correctly install and use insulation nail accessories

Installation sequence: When installing insulation nail accessories, the correct sequence should be followed. Generally, the sleeve is first placed on the insulation nail (if there is a sleeve), and then the insulation nail is inserted into the hole drilled on the surface of the base layer in advance. Then, the gasket and nut are installed, and the nut is tightened with appropriate tools. During the installation process, attention should be paid to maintaining the verticality and levelness of the insulation nails, ensuring that all accessories are installed in place without any omissions or looseness.

Tightening force: The tightening force of the nut should be moderate, neither too loose to fix the insulation material firmly, nor too tight to damage the insulation nails or insulation material. In practical operation, the appropriate tightening torque can be determined based on factors such as the type, thickness, base condition, and design requirements of the insulation material, referring to relevant installation specifications or technical guidelines. For example, for general building exterior wall insulation systems, the tightening torque of nuts may be within a certain range (such as 30-50 N · m), and the specific value needs to be adjusted according to the actual situation.

Inspection and maintenance: After the installation of the insulation system is completed, the installation of insulation nail accessories should be checked in a timely manner to ensure that all accessories are installed firmly, without looseness or deformation. During the use of the insulation system, regular maintenance and inspection should also be carried out, especially after experiencing severe weather (such as strong wind, rainstorm) or long-term use, check whether the insulation nail accessories are damaged or loose, and if there is any problem, repair or replace them in a timely manner. At the same time, attention should be paid to avoiding random drilling, nailing, and other operations on the insulation system to avoid damaging the insulation nail accessories and the overall performance of the insulation system.

4、 Market status and development trend of insulation nail accessories

Market situation

In terms of demand: With the continuous improvement of building energy-saving requirements and the widespread development of insulation engineering, the market demand for insulation nail accessories continues to grow. Whether it is the insulation construction of new buildings or the energy-saving renovation of existing buildings, a large number of insulation nail accessories are required. In addition, there is a significant demand for insulation nail fittings for equipment and pipeline insulation in industrial sectors such as chemical, power, and petroleum industries.

Supply side: Currently, the market competition for insulation nail accessories is fierce, with numerous suppliers. There are both large professional manufacturers and numerous small workshop style enterprises. Large manufacturers usually have advanced production equipment, strict quality control systems, and strong research and development capabilities, which can provide high-quality and diversified insulation nail accessories products; Small businesses often have a certain price advantage, but product quality and performance may vary.

Price trend: The price of insulation nail accessories is influenced by various factors, such as raw material prices, production processes, product quality, market competition, etc. Overall, due to fierce market competition, the prices of insulation nail accessories are relatively stable, but there are still certain differences in prices among different brands and types of products. When choosing insulation nail accessories, one should not only consider the price, but also take into account factors such as product quality, performance, and after-sales service, and choose products with high cost-effectiveness.

Development Trends

Product Innovation: With the continuous advancement of technology and the continuous development of insulation technology, insulation nail accessories will continue to make breakthroughs in product design, material selection, and functional innovation. For example, developing new high-strength, corrosion-resistant, and high-temperature resistant materials to improve the performance and service life of insulation nail accessories; Develop gaskets with better insulation and anti slip properties to further optimize the effectiveness of the insulation system; Design more convenient and efficient installation methods to reduce construction difficulty and costs.

Green environmental protection: With the increasing awareness of environmental protection, green environmental protection will become an important direction for the development of insulation nail accessories. In the future, insulation nail accessories will pay more attention to using environmentally friendly materials to reduce pollution to the environment; At the same time, more attention will be paid to energy conservation and emission reduction in the production process, reducing energy consumption and pollutant emissions.

Intelligence and informatization: With the application of technologies such as the Internet of Things and big data, insulation nail accessories will also develop towards intelligence and informatization. For example, by installing sensors on insulation nail accessories, the fixed status and temperature changes of the insulation system can be monitored in real time, and this information can be transmitted to the monitoring center to achieve remote monitoring and management of the insulation system. This will help identify problems in a timely manner and take corresponding measures to improve the reliability and safety of the insulation system.

As an important component of the insulation system, insulation nail accessories play a crucial role in the installation quality and insulation effect of the insulation system, although they occupy a small proportion in the entire insulation project. When selecting, using, and developing insulation nail accessories, various factors need to be fully considered, constantly innovated and improved to meet the needs of building energy conservation and insulation technology development