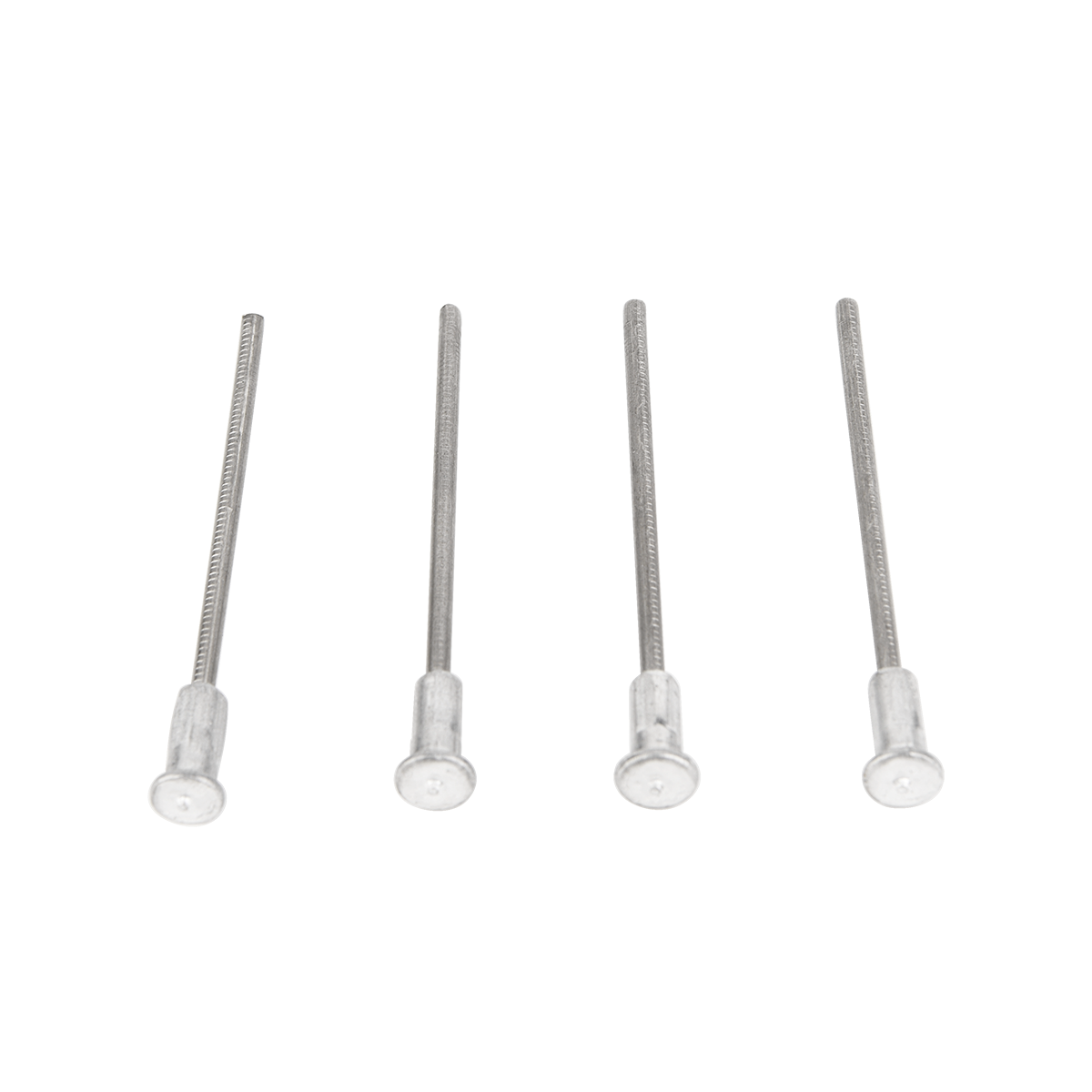

Insulation Fixings Pins

Insulation fixings pins are specialized components that play a crucial role in ensuring the stabilit

Contact

Product Detail

Insulation fixings pins are specialized components that play a crucial role in ensuring the stability and effectiveness of insulation systems in a wide range of applications. These pins are engineered to provide a secure and reliable means of attaching insulation materials to various surfaces.

Insulation fixings pins are typically made from materials that offer a combination of strength, durability, and resistance to environmental factors. Common materials include stainless steel, which provides excellent corrosion resistance, or high-quality plastics that can withstand temperature variations and mechanical stress.

In the construction industry, insulation fixings pins are indispensable for attaching insulation to the exterior or interior of buildings. For example, when insulating the roof of a residential building, these pins are used to secure the insulation boards firmly to the underlying structure. This helps to prevent the insulation from shifting or detaching due to wind, gravity, or other external forces. The pins create a stable connection that ensures the insulation remains in place, providing consistent thermal protection and reducing energy consumption.

In industrial settings, such as factories and processing plants, insulation fixings pins are used to attach insulation to pipes, vessels, and equipment. This is particularly important in applications where high temperatures or corrosive substances are present. The pins help to maintain the integrity of the insulation layer, protecting workers from potential burns and reducing heat loss or gain, which can have a significant impact on process efficiency and energy costs.

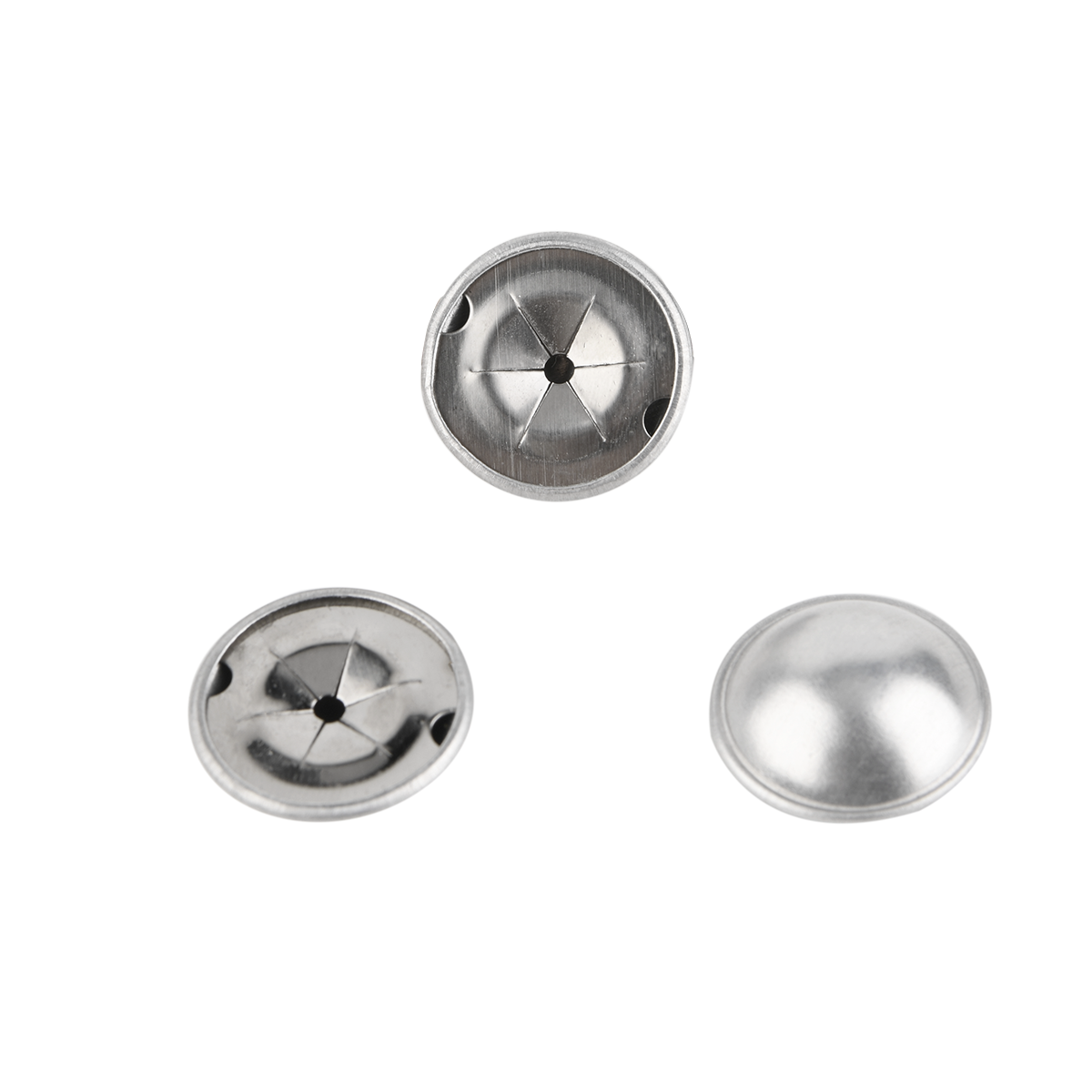

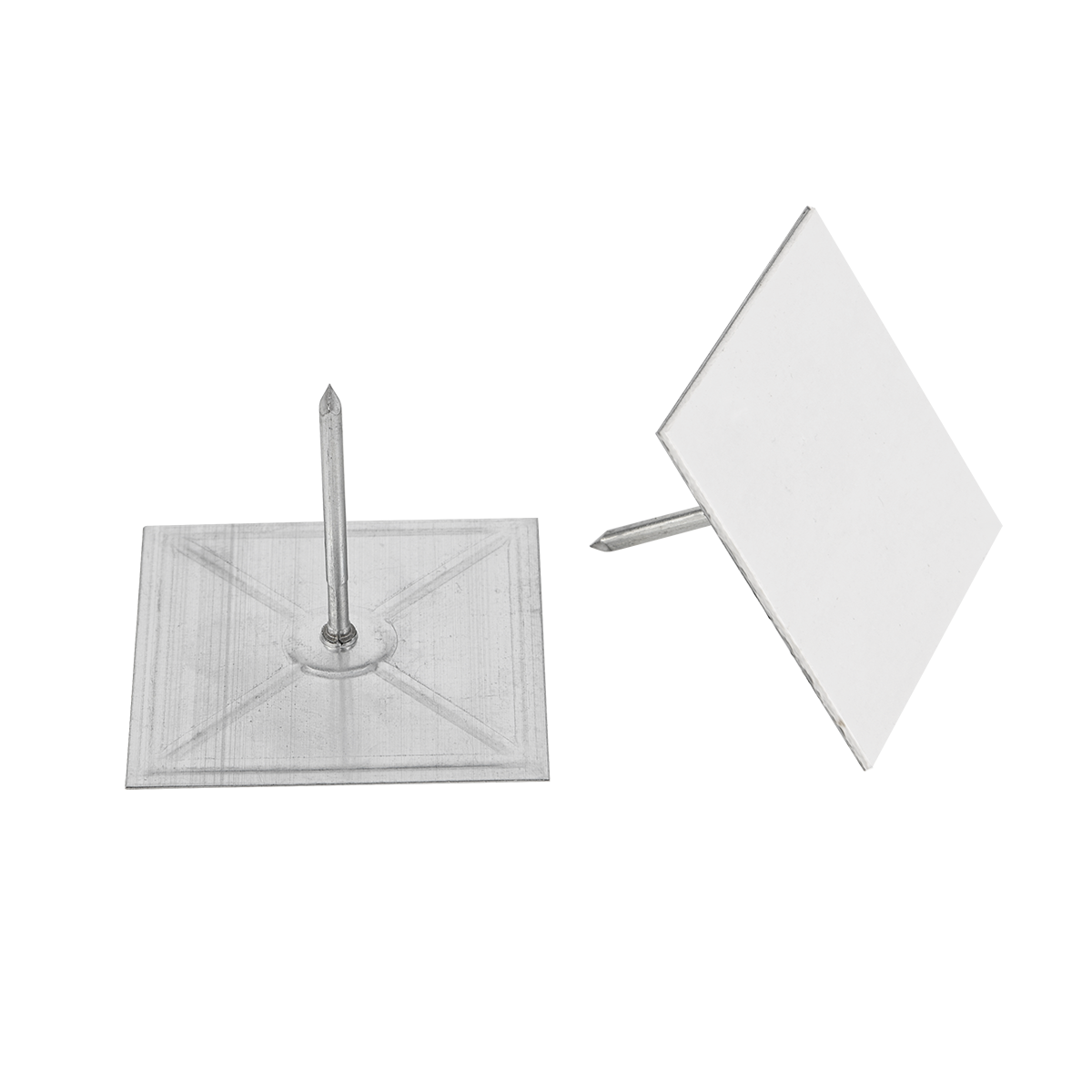

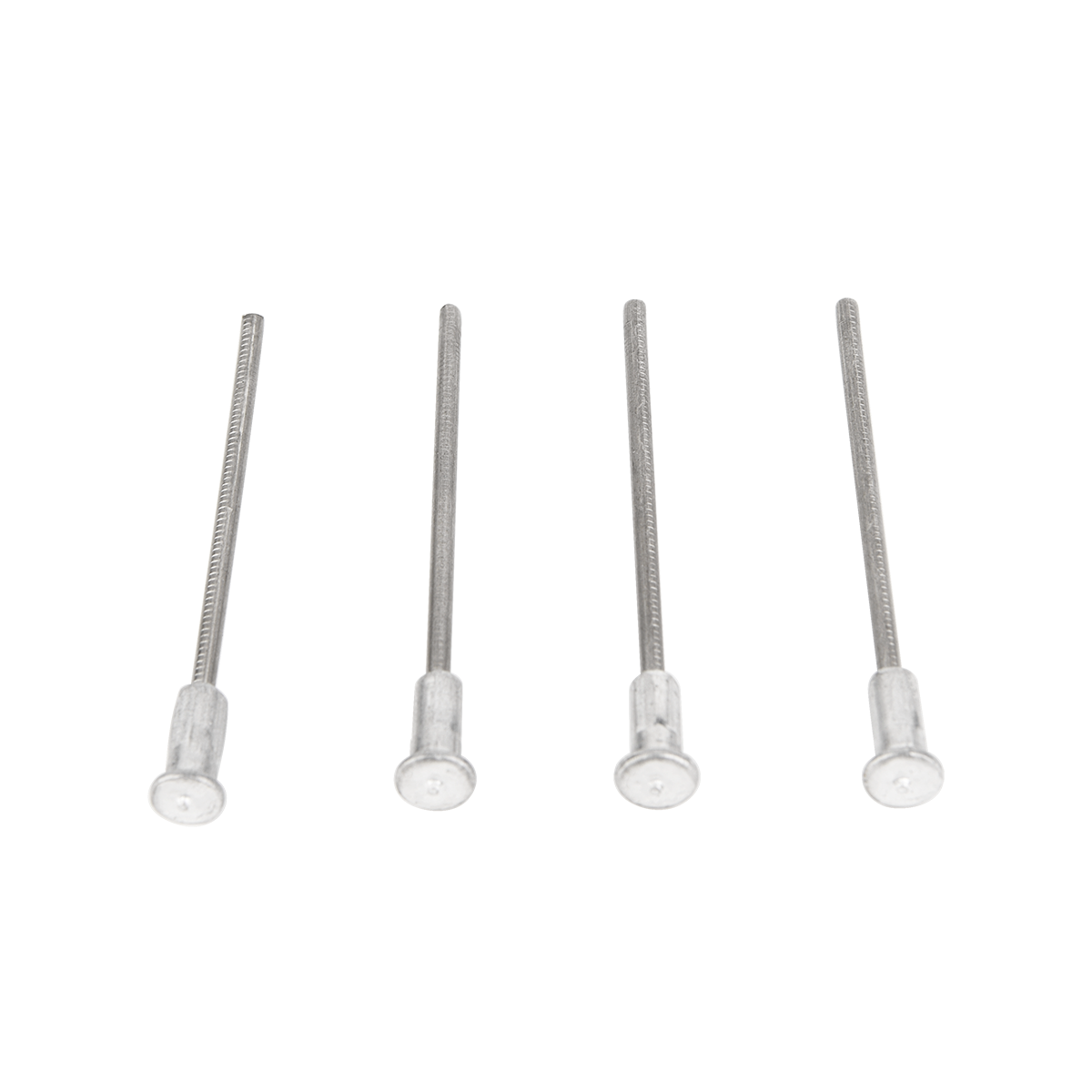

One of the key features of insulation fixings pins is their design. They often have sharp tips to facilitate easy penetration into the substrate, whether it's wood, concrete, or metal. Some pins may also have barbs or threads to enhance their grip and prevent pull-out. The head of the pin can vary in shape and size, depending on the specific requirements of the insulation material and the application.

The choice of insulation fixings pins depends on several factors. The type and thickness of the insulation material, the nature of the substrate, the expected load and stress, and the environmental conditions all need to be considered. For instance, in a marine environment where saltwater exposure is a concern, pins made from materials with superior corrosion resistance would be preferred.

Installation of insulation fixings pins requires proper tools and techniques to ensure they are inserted correctly and provide the desired level of fixation. This may involve using a hammer, a power drill, or a specialized installation tool, depending on the type of pin and the substrate. It's important to follow manufacturer guidelines and safety precautions during the installation process to avoid damage to the insulation or injury to the installer.

Insulation fixings pins also contribute to the overall fire safety of the insulation system. In some cases, they are designed to meet specific fire resistance standards, helping to prevent the spread of fire and smoke within a building or industrial facility.

In addition to their functional role, insulation fixings pins can also have an impact on the aesthetic appearance of the insulated surface. Some pins are designed to be minimally visible or can be covered with caps or sealants to provide a more seamless finish.

In summary, insulation fixings pins are an essential element in achieving a reliable and efficient insulation system. Their proper selection, installation, and maintenance are crucial for ensuring the performance and longevity of the insulation, as well as for providing energy savings, safety, and comfort in various applications.

Title: Insulation Pins Fasteners

Introduction:

Insulation pins fasteners are essential components in the field of insulation installation. These fasteners play a crucial role in securing insulation materials in place, ensuring proper thermal and acoustic insulation, and enhancing the overall energy efficiency of buildings and industrial facilities. In this comprehensive introduction, we will explore the various aspects of insulation pins fasteners, including their types, features, applications, benefits, and installation methods.

Types of Insulation Pins Fasteners:

There are several types of insulation pins fasteners available in the market, each designed to meet specific insulation requirements. Some of the common types include:

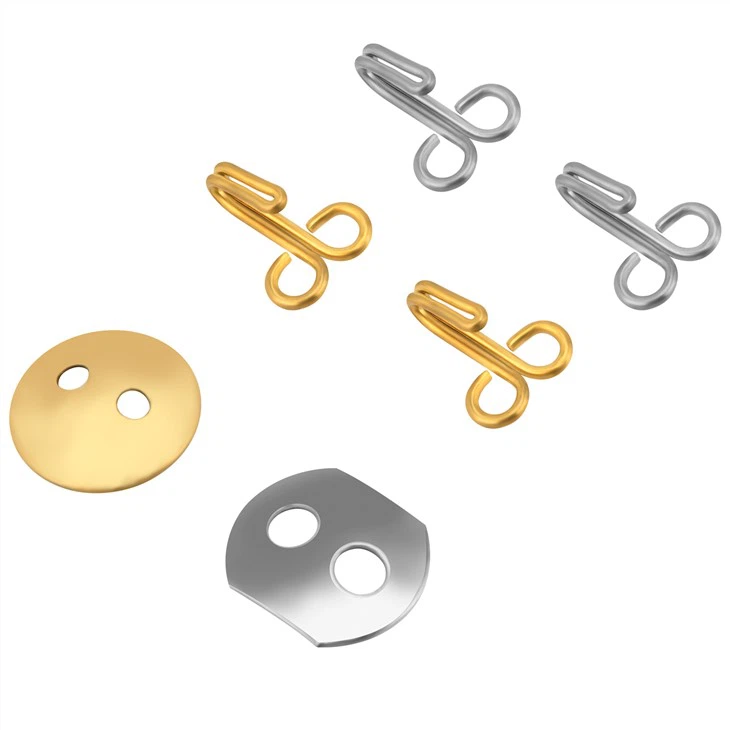

1.Plastic Insulation Pins: These pins are made of high-quality plastic materials and are known for their durability and resistance to corrosion. They are lightweight and easy to install, making them ideal for a wide range of insulation applications. Plastic insulation pins come in different lengths and diameters to accommodate various insulation thicknesses.

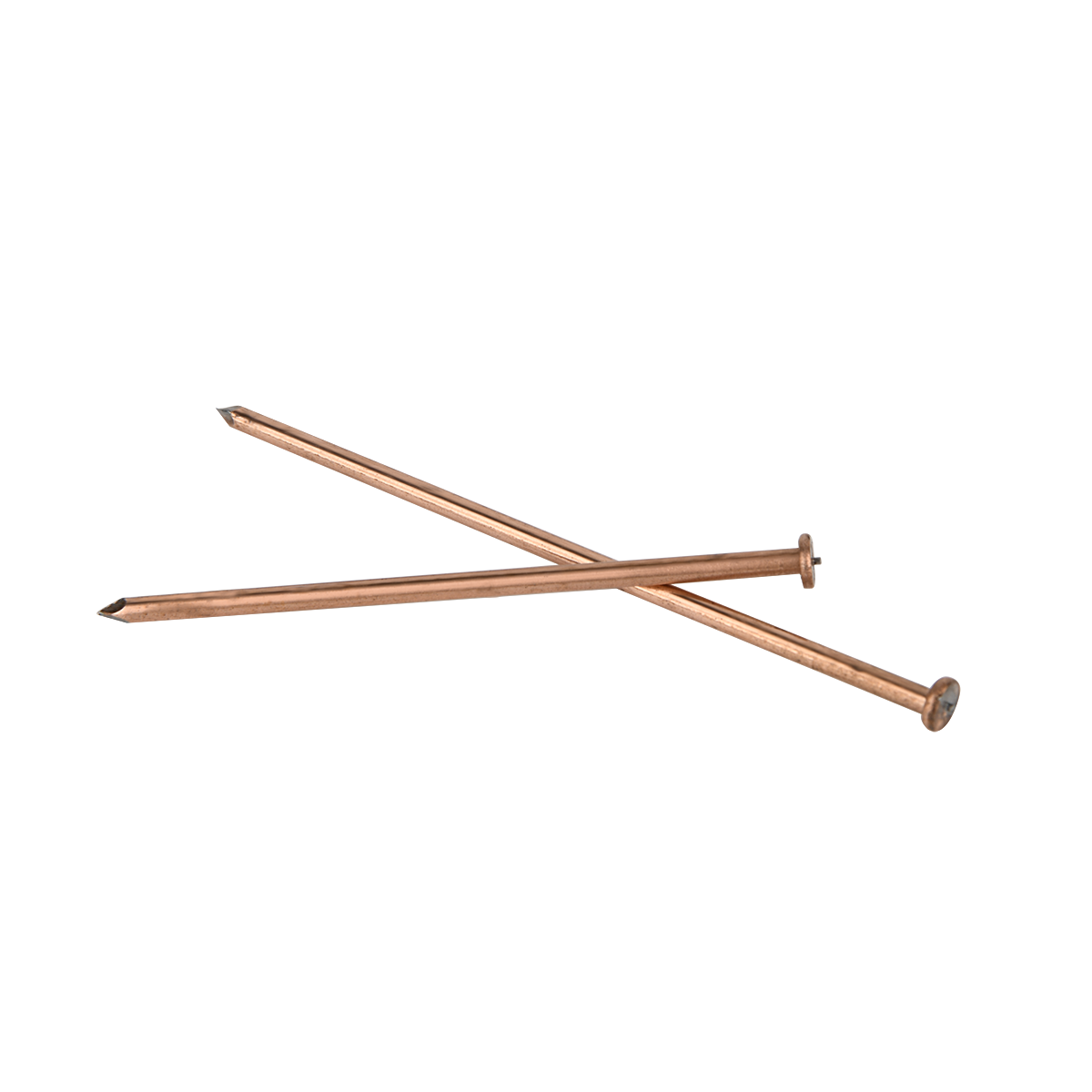

Metal Insulation Pins: Metal pins are typically made of stainless steel or galvanized steel and offer superior strength and durability. They are suitable for heavy-duty insulation applications and can withstand harsh environmental conditions. Metal insulation pins are often used in industrial settings where high temperatures and corrosive substances are present.

Self-Adhesive Insulation Pins: As the name suggests, these pins have a self-adhesive backing that allows them to stick directly to the surface without the need for additional fasteners. Self-adhesive insulation pins are convenient to use and provide a quick and easy installation solution. They are commonly used in areas where drilling or nailing is not possible or desirable.

Cable Tie Insulation Pins: Cable tie insulation pins are designed to hold insulation materials in place by using cable ties. These pins are typically made of plastic and have a loop or hook at one end for attaching the cable tie. Cable tie insulation pins are versatile and can be used in a variety of applications, including bundling and securing insulation materials.

Features of Insulation Pins Fasteners:

Insulation pins fasteners possess several features that make them highly effective in insulation installations. Some of the key features include:

Strong Holding Power: Insulation pins fasteners are designed to provide a secure hold on insulation materials, preventing them from sagging, shifting, or falling off. They have a sharp point or tip that easily penetrates the insulation and a wide head or flange that distributes the load evenly, ensuring a stable and reliable fastening.

Corrosion Resistance: Many insulation pins fasteners are made of materials that are resistant to corrosion, such as stainless steel or plastic with anti-corrosion coatings. This makes them suitable for use in environments where moisture, chemicals, or other corrosive substances are present. Corrosion-resistant fasteners ensure long-term durability and performance of the insulation system.

Temperature Resistance: Insulation pins fasteners are often required to withstand high temperatures, especially in industrial applications. Some fasteners are made of materials that can handle extreme temperatures without degrading or losing their holding power. This ensures that the insulation remains in place even in hot environments.

Versatility: Insulation pins fasteners come in different sizes, shapes, and types, allowing them to be used in a wide variety of insulation applications. They can be used with different types of insulation materials, including fiberglass, foam, mineral wool, and more. Additionally, some fasteners can be adjusted or customized to fit specific installation requirements.

Applications of Insulation Pins Fasteners:

Insulation pins fasteners find extensive applications in various industries and sectors. Some of the common applications include:

Building Construction: In the construction industry, insulation pins fasteners are used to secure insulation materials in walls, ceilings, floors, and roofs. They help improve the thermal and acoustic performance of buildings, reduce energy consumption, and enhance indoor comfort. Insulation pins fasteners are also used in fireproofing applications to hold insulation materials in place and prevent the spread of fire.

Industrial Facilities: Industrial facilities such as factories, warehouses, and power plants require effective insulation to control temperature, reduce noise, and protect equipment. Insulation pins fasteners are used to install insulation on pipes, ducts, boilers, and other industrial equipment. They ensure proper insulation coverage and prevent heat loss or gain, improving energy efficiency and reducing operating costs.

HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems rely on insulation to maintain efficient operation and provide comfortable indoor environments. Insulation pins fasteners are used to secure insulation materials on HVAC ducts, pipes, and equipment. They help prevent condensation, reduce noise transmission, and improve the overall performance of the HVAC system.

Automotive Industry: The automotive industry uses insulation pins fasteners to insulate vehicle interiors, engine compartments, and exhaust systems. These fasteners help reduce noise, vibration, and heat transfer, improving the driving experience and protecting vehicle components.

Benefits of Insulation Pins Fasteners:

Using insulation pins fasteners offers several benefits, both for the installer and the end user. Some of the main benefits include:

Improved Insulation Performance: By securely holding insulation materials in place, insulation pins fasteners ensure proper insulation coverage and minimize air gaps or voids. This leads to improved thermal and acoustic insulation performance, reducing energy consumption and noise levels.

Enhanced Durability: Insulation pins fasteners are designed to withstand the rigors of installation and long-term use. They provide a stable and reliable fastening solution that helps extend the lifespan of the insulation system and reduce maintenance costs.

Time and Cost Savings: Insulation pins fasteners are easy to install and require minimal tools and equipment. This saves time and labor costs compared to traditional fastening methods such as drilling or nailing. Additionally, their durability and long service life can result in cost savings over the life of the insulation system.

Versatility and Customization: With a wide range of types and sizes available, insulation pins fasteners can be customized to meet specific installation requirements. They can be used with different insulation materials and in various applications, providing flexibility and versatility for installers.

Installation Methods of Insulation Pins Fasteners:

The installation of insulation pins fasteners depends on the type of fastener and the specific application. Here are some general installation methods:

Manual Installation: For small-scale installations or when access is limited, insulation pins fasteners can be installed manually. This typically involves using a hammer or pliers to drive the pin into the surface. Care should be taken to ensure that the pin is inserted straight and perpendicular to the surface to achieve a secure hold.

Power Tool Installation: In larger installations or when working with hard surfaces, power tools such as a pneumatic nail gun or screw gun can be used to install insulation pins fasteners. These tools provide faster and more efficient installation, but proper safety precautions should be taken to avoid accidents.

Self-Adhesive Installation: Self-adhesive insulation pins fasteners can be simply peeled off the backing and pressed onto the surface. No additional tools or fasteners are required, making this method quick and easy. However, it is important to ensure that the surface is clean and dry for a proper bond.

Cable Tie Installation: Cable tie insulation pins are installed by threading a cable tie through the loop or hook on the pin and tightening it around the insulation material. This method is suitable for bundling and securing insulation materials and provides a flexible and adjustable fastening solution.

Conclusion:

Insulation pins fasteners are an important part of insulation installations, providing a secure and reliable way to hold insulation materials in place. With their various types, features, applications, benefits, and installation methods, these fasteners offer a versatile and effective solution for improving thermal and acoustic insulation in buildings, industrial facilities, HVAC systems, and the automotive industry. By choosing the right insulation pins fasteners and following proper installation procedures, installers can ensure optimal insulation performance and energy efficiency.