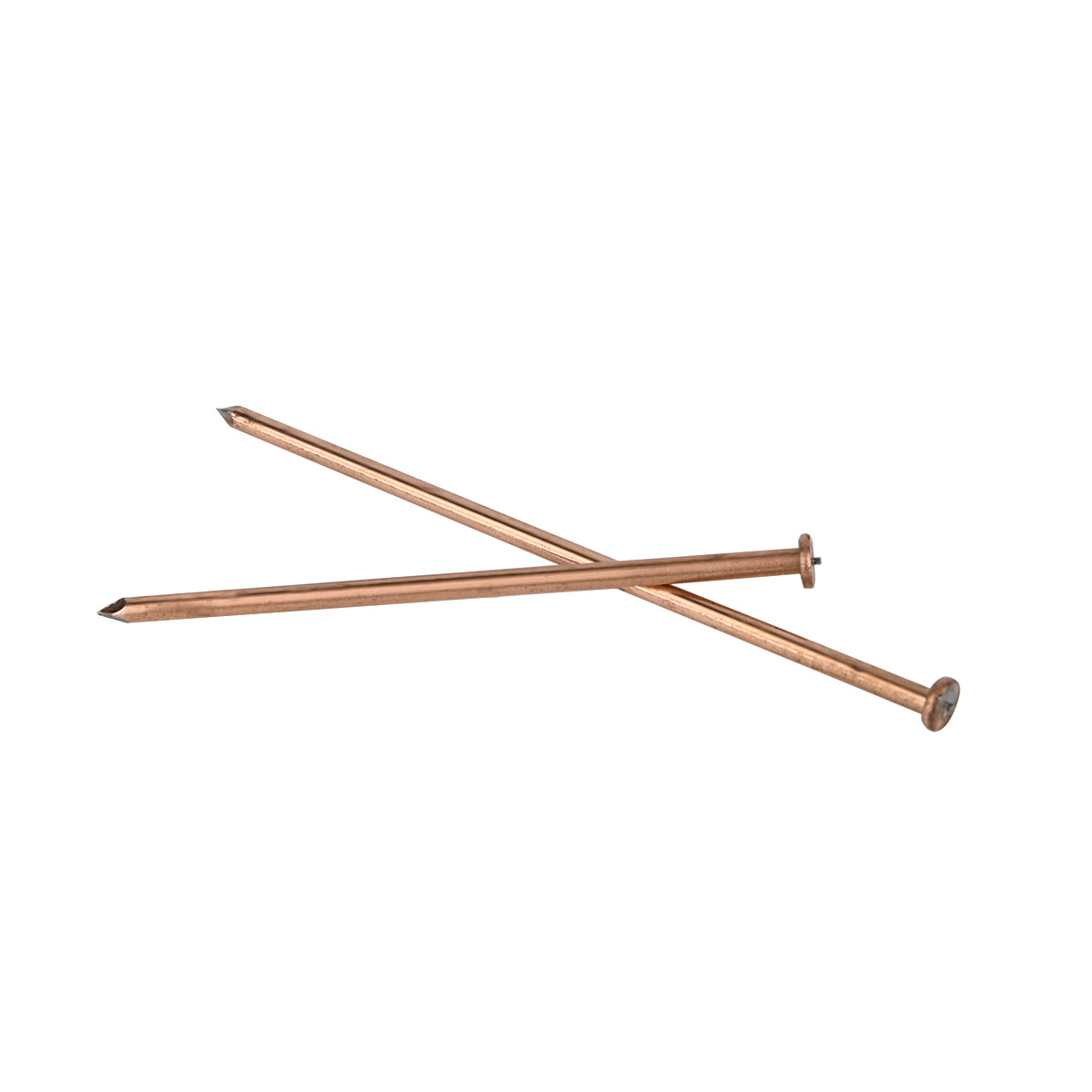

Perforated Base Insulation Pins

Insulation pins are indispensable components in various construction and industrial applicatio

Contact

Product Detail

Insulation pins are indispensable components in various construction and industrial applications, particularly in the installation of thermal and acoustic insulation materials. Perforated base insulation pins represent a specialized type of pin designed to provide enhanced stability and performance in demanding environments.

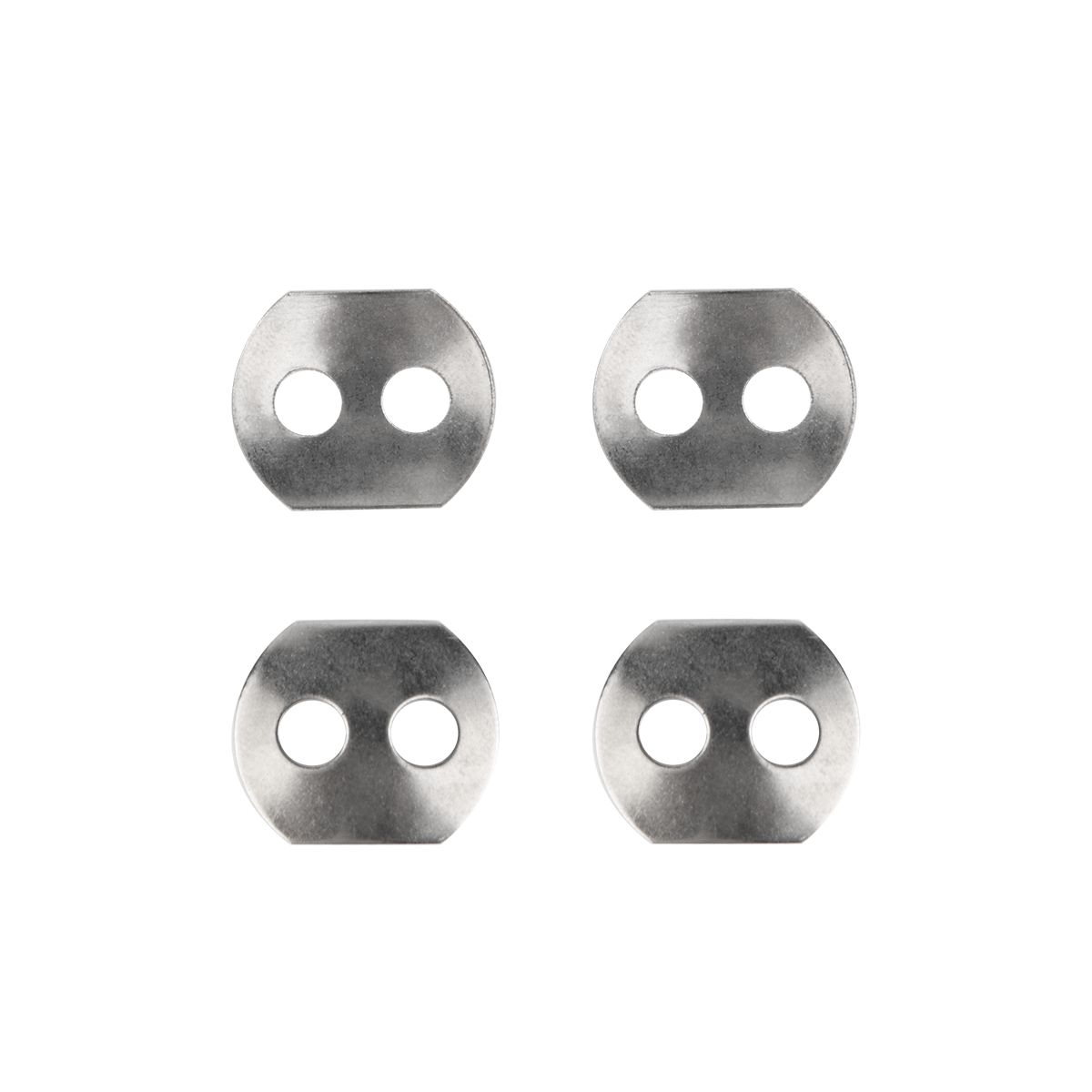

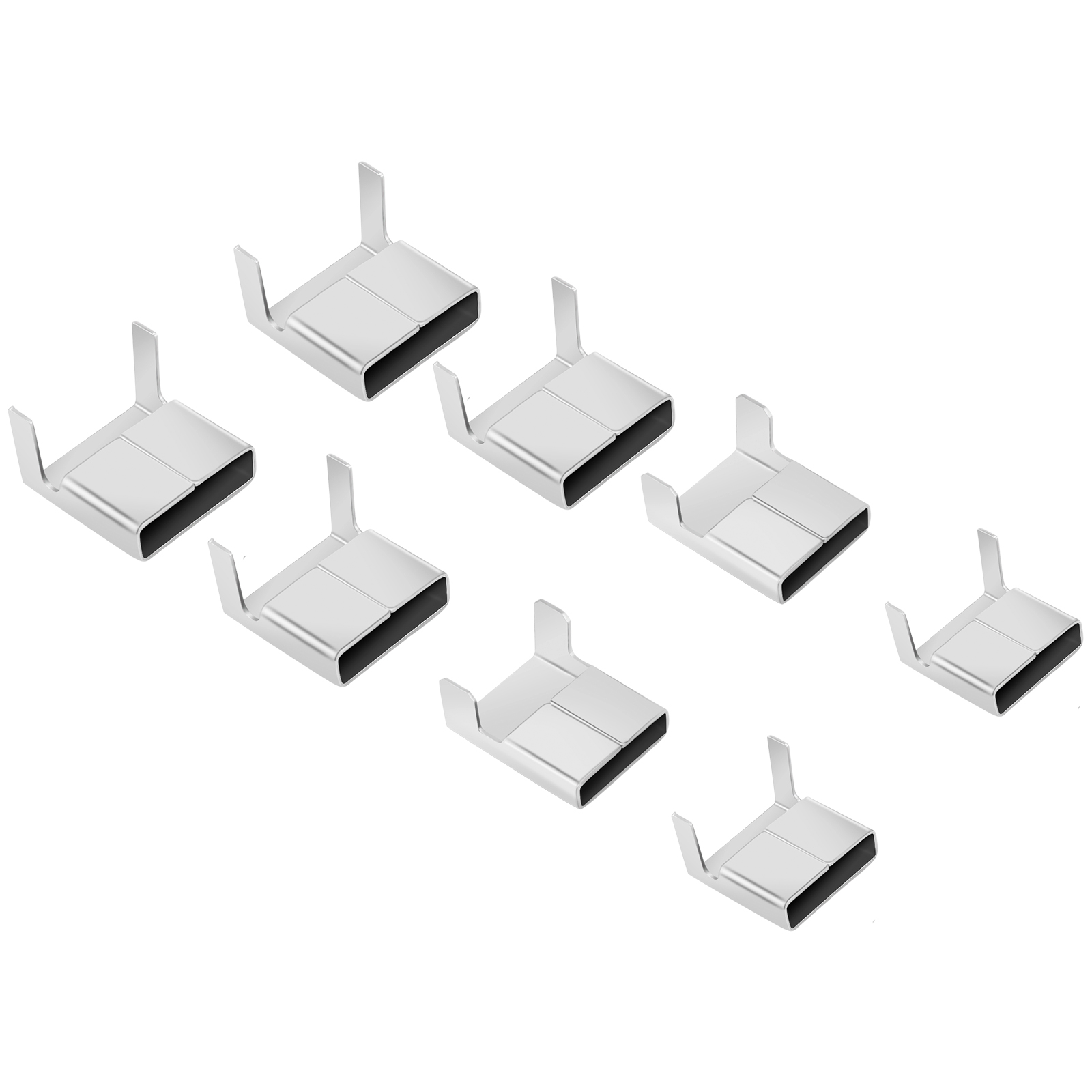

The primary function of perforated base insulation pins is to secure insulation materials, such as fiberglass, rock wool, or foam, to structural surfaces like walls, ceilings, and ductwork. The unique feature of these pins is their perforated base, which offers several advantages over standard pins.

Firstly, the perforations in the base of the pin allow for better adhesion to the substrate. When the pin is inserted into the surface, the perforations create additional contact points, distributing the load more evenly and preventing the pin from pulling out under stress. This increased stability is particularly important in applications where the insulation material may be subjected to high temperatures, vibrations, or mechanical forces.

Secondly, the perforated base facilitates better air circulation and moisture management. In insulated structures, trapped moisture can lead to issues such as mold growth, reduced insulation performance, and structural damage. The perforations in the pin base allow for improved airflow and drainage, helping to maintain a dry and healthy environment within the insulation layer.

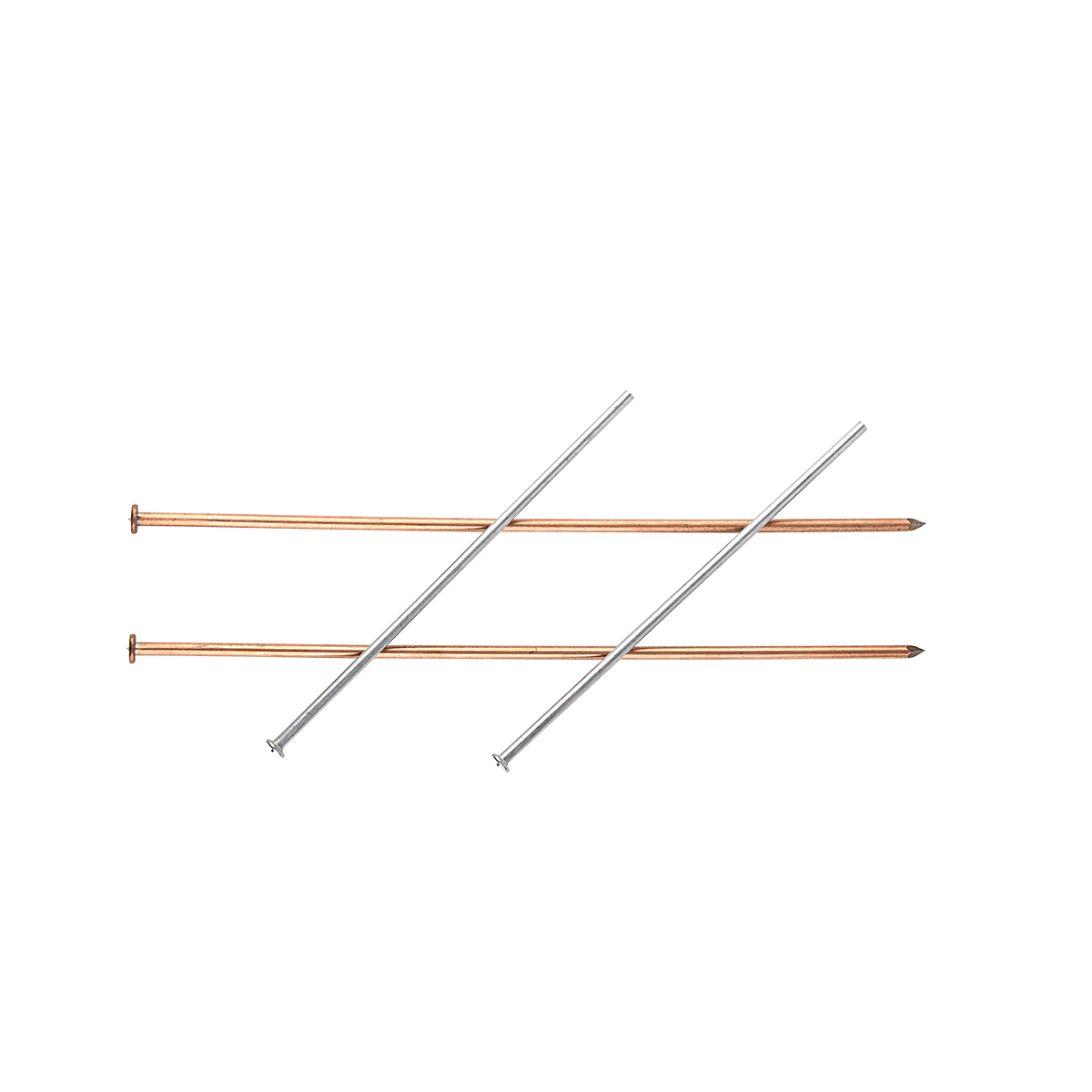

Perforated base insulation pins are typically manufactured from high-quality materials like stainless steel, aluminum, or plastic, ensuring durability and resistance to corrosion. They are available in various lengths and diameters to accommodate different types and thicknesses of insulation materials.

When installing perforated base insulation pins, it is important to ensure that they are inserted at appropriate intervals and depths to provide adequate support. Following manufacturer guidelines and industry standards is crucial to ensure that the insulation system functions effectively and lasts for an extended period.