Insulation Pins selection and installation

There are several key steps and precautions to follow when selecting and installing insulation pins

Contact

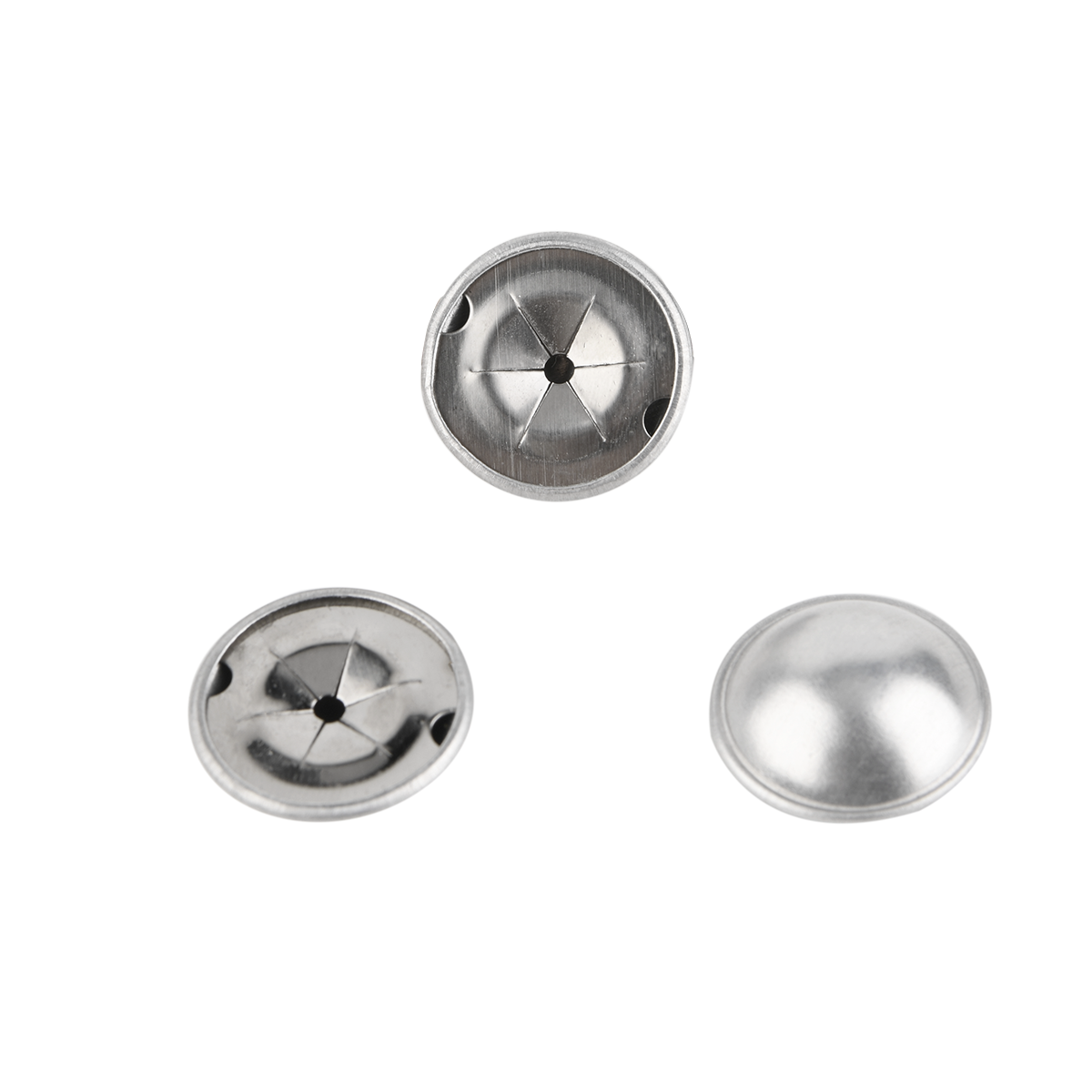

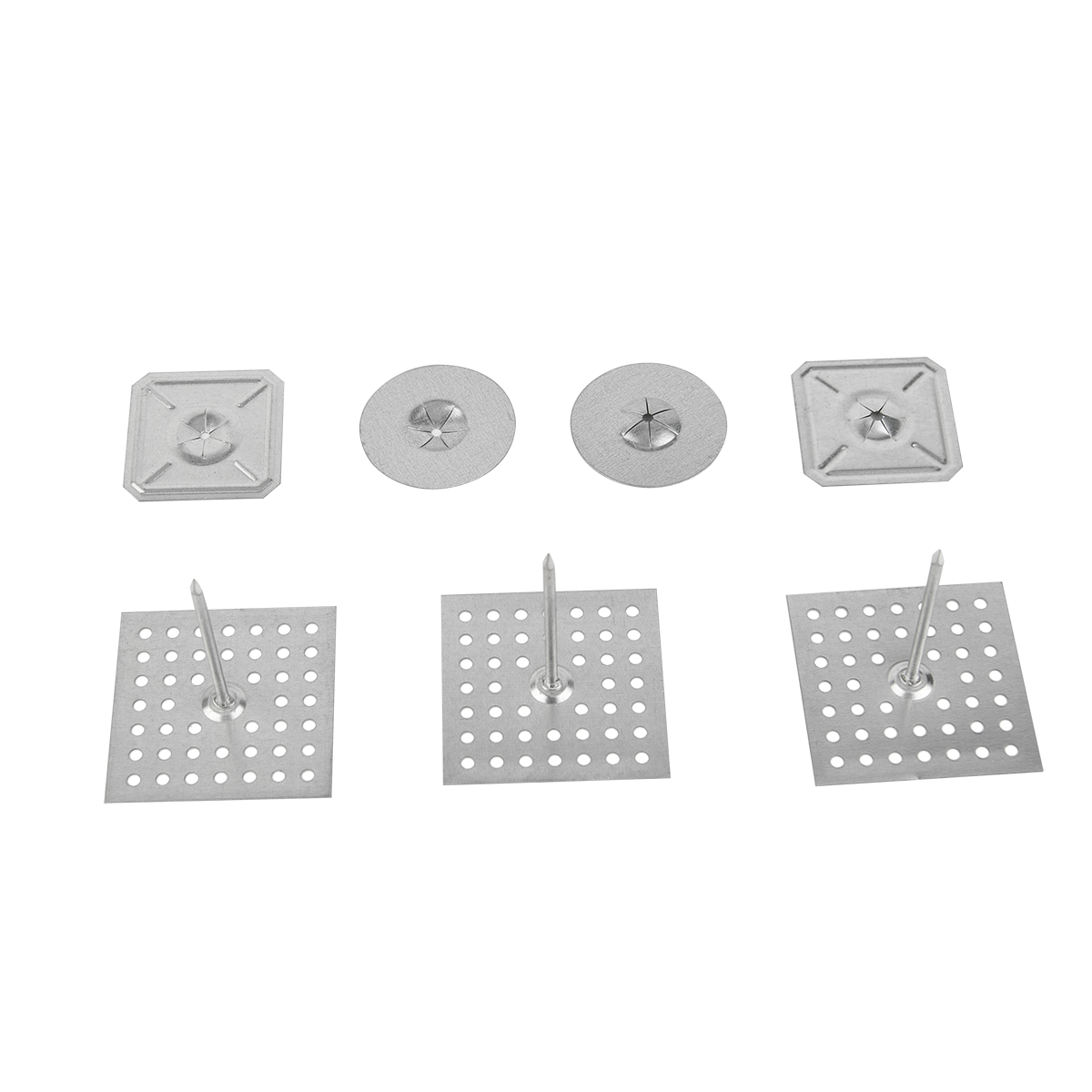

Product Detail

There are several key steps and precautions to follow when selecting and installing insulation pins to ensure that the final installation meets the expected requirements.

Purchase Guide

1. Determine requirements: Firstly, it is necessary to clarify the specific purpose and working environment of the insulation pin. Different application scenarios may require different types of insulation materials and designs. For example, power transmission in high-voltage environments may require pins with higher insulation performance, while pipeline supports in chemical plants require stronger corrosion resistance.

2. Choose appropriate materials: Select appropriate materials according to the requirements of the work environment. Common insulation materials include engineering plastics, ceramics, fiberglass reinforced plastics (FRP), etc. Each material has its unique properties and scope of application.

3. Consider load capacity: Select insulation pins with sufficient load capacity based on the weight and size of the equipment or pipeline that needs to be supported. A too small load capacity may cause the pin to fail during use, affecting the safety and stability of the entire system.

4. Check certification and standards: Ensure that the selected insulation pins comply with relevant industry standards and safety certifications. This not only ensures the quality and performance of the product, but also avoids safety hazards caused by the use of unqualified products.

Installation steps

1. Preparation: Before installation, ensure that all tools and materials are ready. Common tools include screwdrivers, wrenches, drills, etc. At the same time, the installation site should be cleaned to ensure the safety and cleanliness of the work area.

2. Positioning and measurement: Determine the installation position of the insulation pin based on the design drawings or actual needs. Use measuring tools for precise positioning and marking to ensure that the installation position of the pin can meet the support requirements of the equipment or pipeline.

3. Fixed Pin: Use appropriate fixing methods (such as bolts, rivets, etc.) to fix the insulation pin to the supporting structure in the predetermined position. Ensure that the pin is firmly and reliably fixed, and can withstand the expected load.

4. Installation of equipment or pipelines: Install the equipment or pipelines that need to be supported on insulation pins. Ensure that the connection between the equipment or pipeline and the pin is stable and will not loosen or slide.

5. Inspection and adjustment: After installation, conduct a comprehensive inspection and adjustment. Ensure that all connection points and fixing points are firm and reliable, without any looseness or damage. Make appropriate adjustments when necessary to ensure the stability and safety of equipment or pipelines.