Self Sticking Insulation Hangers

In the dynamic world of building insulation, self sticking insulation hangers have emerged as a revolutionary solution. These innovative components are designed to simplify the installation process of insulation materials, offering a convenient and efficient alternative to traditional hanger systems. Whether in residential, commercial, or industrial buildings, the proper installation of insulation is crucial for energy efficiency, temperature regulation, and soundproofing. Self sticking insulation hangers play a pivotal role in ensuring that insulation is securely and accurately positioned, enhancing the overall performance of the insulation system.

Contact

Product Detail

Introduction

In the dynamic world of building insulation, self sticking insulation hangers have emerged as a revolutionary solution. These innovative components are designed to simplify the installation process of insulation materials, offering a convenient and efficient alternative to traditional hanger systems. Whether in residential, commercial, or industrial buildings, the proper installation of insulation is crucial for energy efficiency, temperature regulation, and soundproofing. Self sticking insulation hangers play a pivotal role in ensuring that insulation is securely and accurately positioned, enhancing the overall performance of the insulation system.

Design and Structure

Adhesive Component

The most distinctive feature of self sticking insulation hangers is, of course, their adhesive backing. High quality adhesives are used, which are engineered to bond firmly to a variety of building surfaces, including concrete, metal, wood, and drywall. These adhesives are typically pressure sensitive, meaning that they form an immediate bond when pressure is applied. They are also formulated to withstand different environmental conditions, such as temperature fluctuations, humidity, and mechanical stress. For example, in a hot and humid climate, the adhesive should not lose its tackiness or strength, ensuring that the hanger remains securely attached to the surface.

The adhesive layer is often protected by a release liner before installation. This liner is easily removable, exposing the adhesive surface when it's time to attach the hanger. The thickness and composition of the adhesive layer are carefully calibrated to provide sufficient bonding strength while also allowing for easy handling during installation. Some advanced adhesives may even have self leveling properties, which help to create a more uniform and secure bond, especially on uneven surfaces.

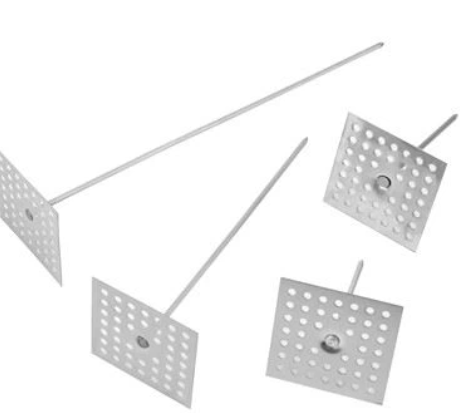

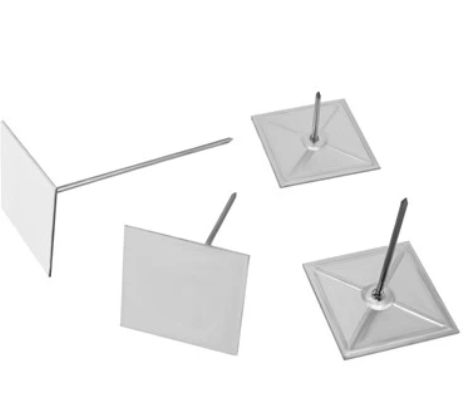

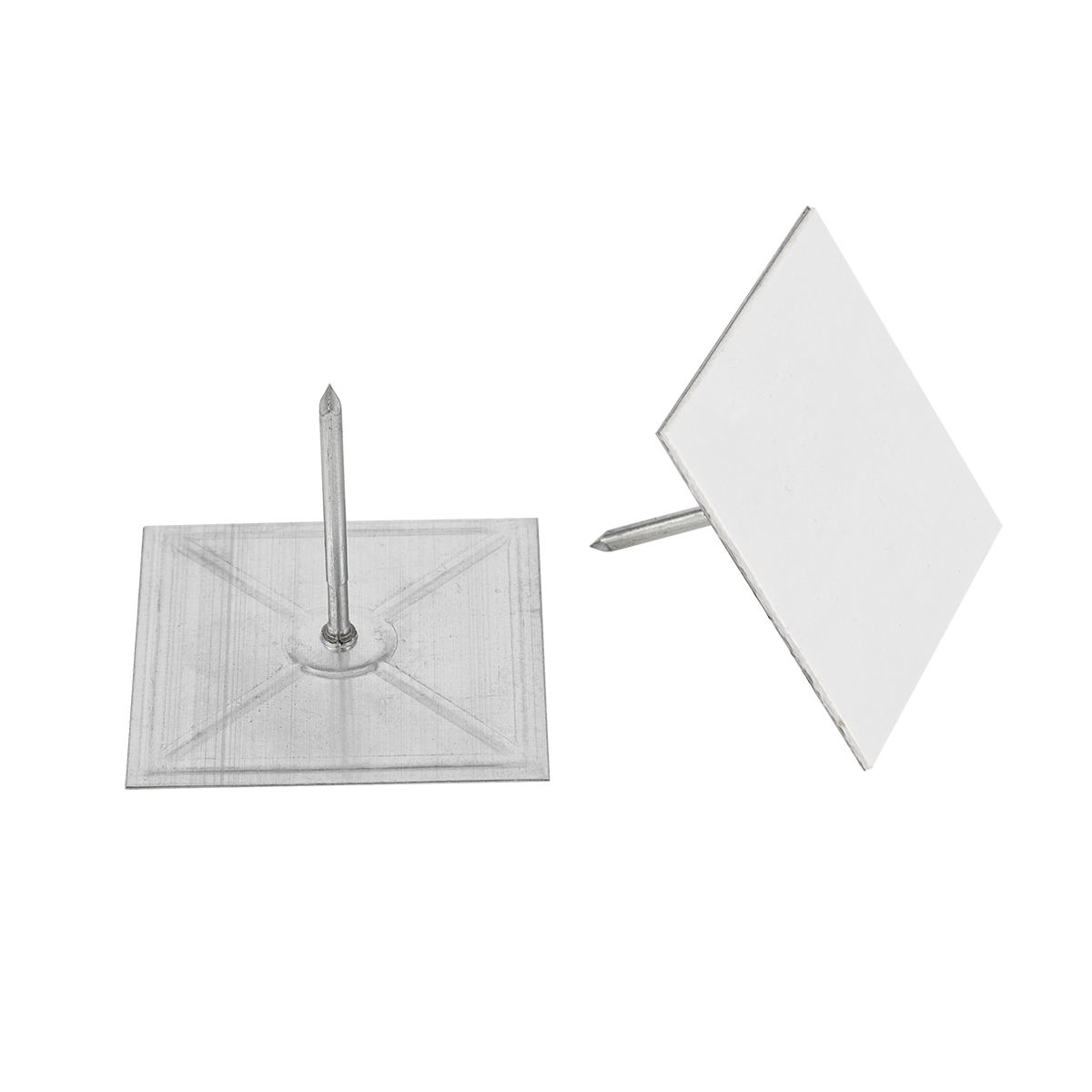

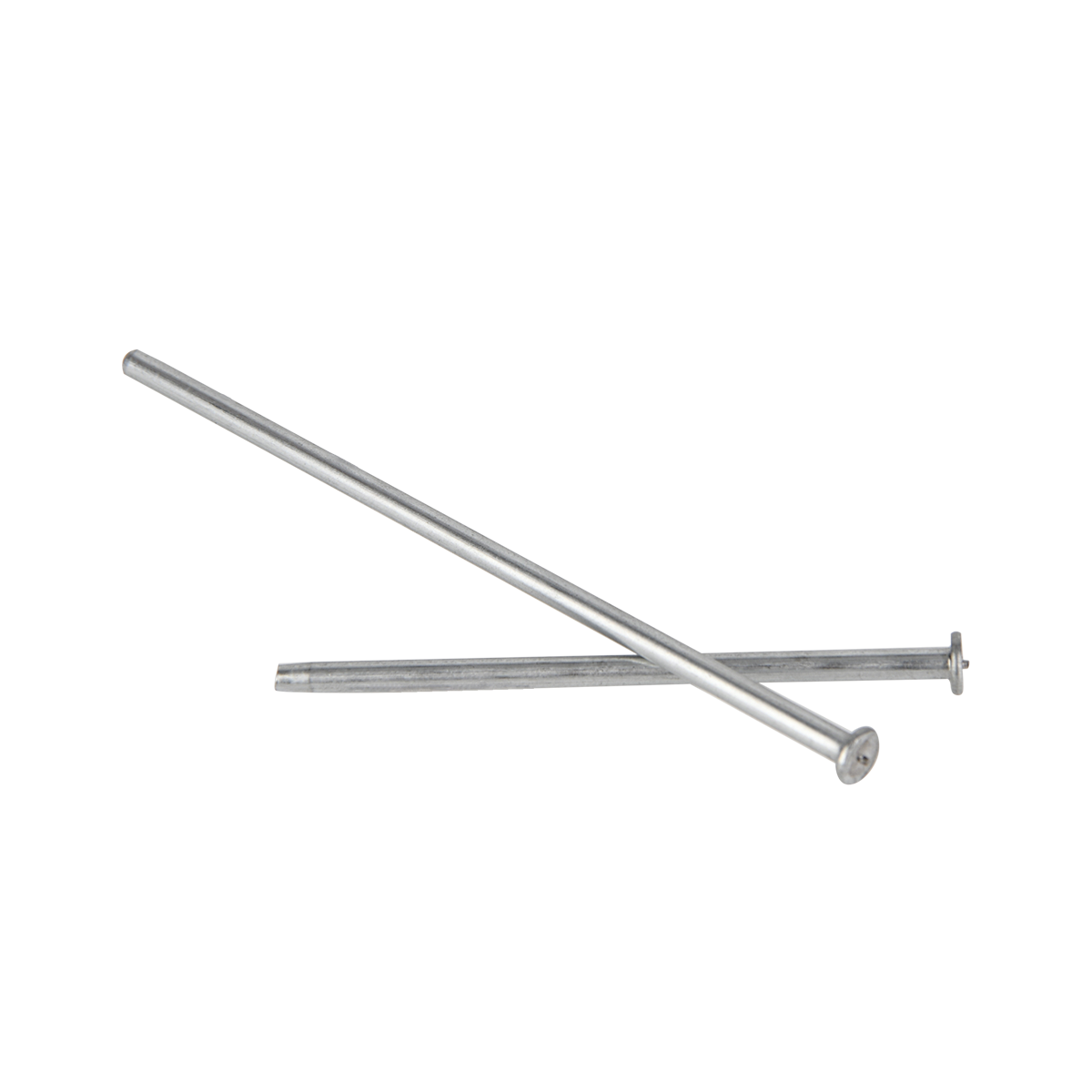

Hanger Body

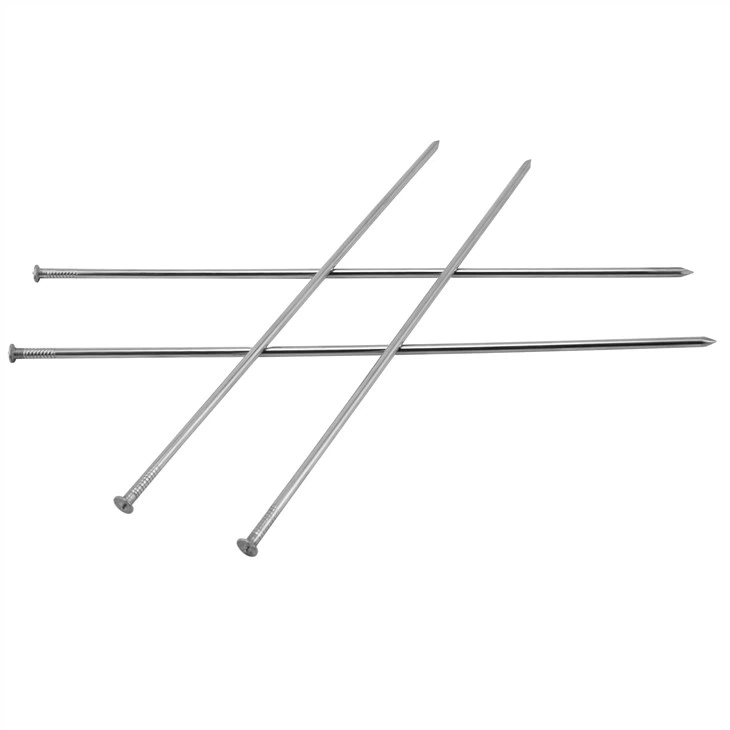

The body of the self sticking insulation hanger is designed to support the insulation material effectively. It is usually made from durable materials such as plastic or metal. Plastic hangers are lightweight, corrosion resistant, and cost effective. They are often injection molded into specific shapes that are optimized for holding different types of insulation, such as fiberglass batts or foam boards. Metal hangers, on the other hand, offer greater strength and load bearing capacity. They are commonly made from galvanized steel or stainless steel to prevent rust and corrosion.

The shape of the hanger body can vary depending on its intended application. Some hangers have a simple, hook like design that allows the insulation to be easily draped over them. Others may have more complex configurations with multiple attachment points or slots to accommodate different insulation thicknesses and installation methods. The surface of the hanger body that comes in contact with the insulation may be textured or have special coatings to improve grip and prevent the insulation from slipping.

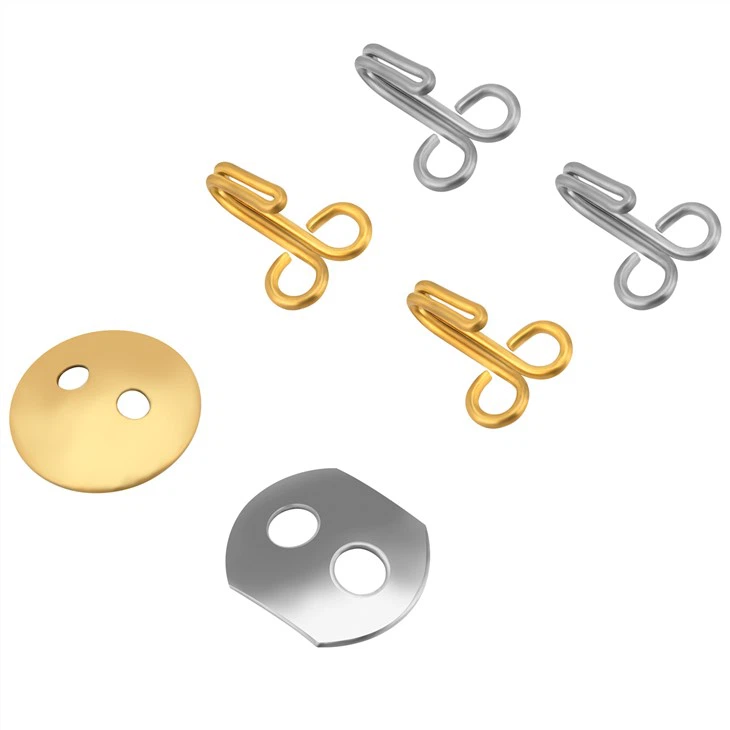

Reinforcement Elements

To enhance the durability and performance of self sticking insulation hangers, reinforcement elements are often incorporated. In plastic hangers, for instance, fiberglass or carbon fiber reinforcements may be added to increase their strength and rigidity. This is particularly important when the hanger needs to support heavy insulation materials or when it is subjected to significant mechanical stress, such as in an industrial setting where there may be vibrations or movement in the building structure.

In metal hangers, additional bracing or reinforcement bars may be welded or attached to the main body of the hanger. These reinforcement elements help to distribute the load more evenly and prevent the hanger from bending or breaking under the weight of the insulation. They also contribute to the overall stability of the insulation installation, ensuring that the insulation remains in place over time.

Function and Importance in Insulation Installation

Simplified Installation Process

One of the primary advantages of self sticking insulation hangers is the significant simplification of the installation process. Traditional insulation hanger systems often require drilling holes, using screws or nails, and in some cases, additional tools and hardware. This can be time consuming, especially in large scale projects, and may also cause damage to the building structure. With self sticking hangers, the installation process is reduced to a few simple steps. The installer simply removes the release liner from the adhesive backing, positions the hanger on the desired surface, and applies pressure to activate the adhesive bond. This not only saves time but also reduces the labor costs associated with insulation installation.

Secure Attachment of Insulation

Self sticking insulation hangers provide a secure and reliable means of attaching insulation to the building structure. The strong adhesive bond ensures that the hanger remains firmly in place, even in the face of environmental factors such as wind, vibration, and temperature changes. This, in turn, helps to keep the insulation material in its proper position, preventing sagging, shifting, or gaps that could compromise the insulation's performance. For example, in a ceiling installation, self sticking hangers can effectively support the weight of the insulation, ensuring that it does not droop over time and maintain a consistent thickness for optimal thermal and acoustic insulation.

Versatility in Applications

These hangers are highly versatile and can be used in a wide range of insulation applications. They are suitable for both interior and exterior installations, making them applicable in residential homes, commercial buildings, and industrial facilities. In residential applications, self sticking hangers can be used to install insulation in attics, walls, and basements. In commercial buildings, they are useful for insulating ceilings, walls, and ductwork. In industrial settings, they can be employed to insulate large scale equipment, storage tanks, and factory walls. Their versatility extends to different types of insulation materials as well, including fiberglass, mineral wool, foam boards, and spray foam insulation.

Installation Process

Surface Preparation

Before installing self sticking insulation hangers, proper surface preparation is essential. The surface where the hanger will be attached should be clean, dry, and free of dust, dirt, grease, and any loose particles. This can be achieved by using a suitable cleaning agent and a clean cloth or brush. If the surface is rough or uneven, it may need to be smoothed or primed to ensure a good bond with the adhesive. For example, on a concrete surface, any protrusions or cracks should be filled and sanded down before installation. In the case of metal surfaces, rust and corrosion should be removed, and a primer may be applied to enhance adhesion.

Hanger Installation

Once the surface is prepared, the installation of the self sticking insulation hanger can commence. The release liner is carefully removed from the adhesive backing of the hanger. It's important to handle the hanger by its edges to avoid touching the adhesive surface, as this could reduce its bonding effectiveness. The hanger is then positioned on the prepared surface at the desired location. It's crucial to ensure that the hanger is level and properly aligned, especially in applications where multiple hangers are being used. Pressure is applied evenly across the entire surface of the hanger using a flat tool, such as a rubber mallet or a hand roller. This pressure activates the adhesive, creating a strong bond between the hanger and the surface.

Insulation Attachment

After the hangers are installed, the insulation material can be attached. Depending on the type of insulation and the design of the hanger, different attachment methods may be used. For fiberglass batts, they can be simply placed over the hooks or slots of the hangers. Foam boards may be attached using additional adhesive or mechanical fasteners in combination with the hangers. In the case of spray foam insulation, the hangers help to hold the expanding foam in place until it cures. It's important to ensure that the insulation is properly seated on the hangers and that there are no gaps or voids between the insulation and the hanger or the building surface.

Types of Self Sticking Insulation Hangers

Ceiling Mounted Self Sticking Hangers

Ceiling mounted self sticking insulation hangers are specifically designed for use in ceiling applications. They are often longer and have a design that allows them to span across ceiling joists or support insulation over large areas. These hangers may have a hook shaped or a multi pronged design to better hold the insulation in place. Some ceiling mounted hangers are also equipped with additional features, such as adjustable height mechanisms, which can be useful when dealing with different ceiling heights or insulation thicknesses. They are commonly used in residential attics, commercial ceilings, and industrial facility roofs.

Wall Mounted Self Sticking Hangers

Wall mounted self sticking insulation hangers are designed for attaching insulation to walls. They are typically smaller and more compact compared to ceiling mounted hangers, as they need to fit between wall studs or other wall framing members. These hangers may have a flat or a curved design, depending on the type of wall surface and the insulation material being used. Wall mounted self sticking hangers are used in both interior and exterior wall insulation projects. In exterior walls, they need to be able to withstand weather conditions, so they are often made from more durable materials and have adhesives with enhanced weather resistance properties.

Pipe and Duct Insulation Self Sticking Hangers

Self sticking insulation hangers for pipes and ducts are specialized components. They are designed to fit around the circumference of pipes or ducts and hold the insulation in place. These hangers may have a split ring or a wrap around design. The adhesive used in these hangers needs to be resistant to the temperature and chemical conditions associated with the pipes or ducts. For example, in a heating or cooling duct system, the hanger's adhesive should be able to withstand the temperature fluctuations of the air flowing through the ducts. Pipe and duct insulation self sticking hangers are essential for maintaining the efficiency of HVAC systems and preventing heat loss or gain in industrial and commercial piping systems.

Challenges and Solutions in Using Self Sticking Insulation Hangers

Adhesive Failure

One of the potential challenges with self sticking insulation hangers is adhesive failure. This can occur due to improper surface preparation, extreme environmental conditions, or the use of low quality adhesives. To address this, it's crucial to follow the manufacturer's guidelines for surface preparation carefully. Using high quality adhesives that are specifically formulated for the intended application and environmental conditions is also essential. In some cases, additional mechanical fasteners may be used in combination with the self sticking hangers as a backup to ensure a secure attachment, especially in areas where the risk of adhesive failure is higher.

Limited Load Bearing Capacity

Depending on the design and material of the self sticking insulation hanger, there may be limitations in its load bearing capacity. This can be a concern when using heavier insulation materials or in applications where there may be additional stress on the hangers. To overcome this, manufacturers are developing stronger and more robust hanger designs. Reinforcement elements, as mentioned earlier, can be added to increase the load bearing capacity. Additionally, proper spacing of the hangers and ensuring that the insulation is evenly distributed across the hangers can help to optimize the load bearing performance.

Compatibility with Different Surfaces

Self sticking insulation hangers need to be compatible with a variety of building surfaces. However, some surfaces may pose challenges in terms of adhesion. For example, some types of plastics or certain painted surfaces may not provide a good bond with the adhesive. To solve this, surface primers or adhesives with enhanced compatibility can be used. In some cases, mechanical attachment methods may need to be considered for surfaces where self sticking adhesives are not suitable.

Future Trends and Innovations

Smart Self Sticking Hangers

With the increasing trend towards smart buildings, there is potential for the development of smart self sticking insulation hangers. These could be equipped with sensors that can monitor the condition of the insulation, such as temperature, humidity, and insulation displacement. The data from these sensors could be transmitted wirelessly to a building management system. This would allow for early detection of any issues, such as insulation degradation or hanger detachment, and enable proactive maintenance. For example, if a sensor detects a change in temperature indicating a gap in the insulation, the building management system could alert the maintenance staff to address the issue before it leads to energy inefficiencies or other problems.

Sustainable and Environmentally Friendly Materials

As the construction industry becomes more focused on sustainability, there will be a growing demand for self sticking insulation hangers made from sustainable and environmentally friendly materials. This could include recycled plastics, bio based adhesives, and recycled metal components. The use of these materials would not only reduce the environmental impact of the construction process but also contribute to the overall sustainability of the building. Manufacturers are likely to invest in research and development to create hangers that are both high performing and eco friendly.

Improved Adhesive Technologies

Ongoing research and development in adhesive technologies are likely to lead to the development of even more advanced adhesives for self sticking insulation hangers. These adhesives may offer stronger bonds, faster curing times, and better resistance to a wider range of environmental factors. They may also be more user friendly, with improved application methods and less sensitivity to surface conditions. New adhesive chemistries may be developed that can bond to a broader range of materials, further expanding the versatility of self sticking insulation hangers.

In conclusion, self sticking insulation hangers have revolutionized the insulation installation process, offering simplicity, security, and versatility. Despite some challenges, ongoing innovations and developments in design, materials, and adhesive technologies are likely to further enhance their performance and expand their applications in the future. Their continued evolution will play a crucial role in improving the energy efficiency and overall performance of buildings across various sectors.