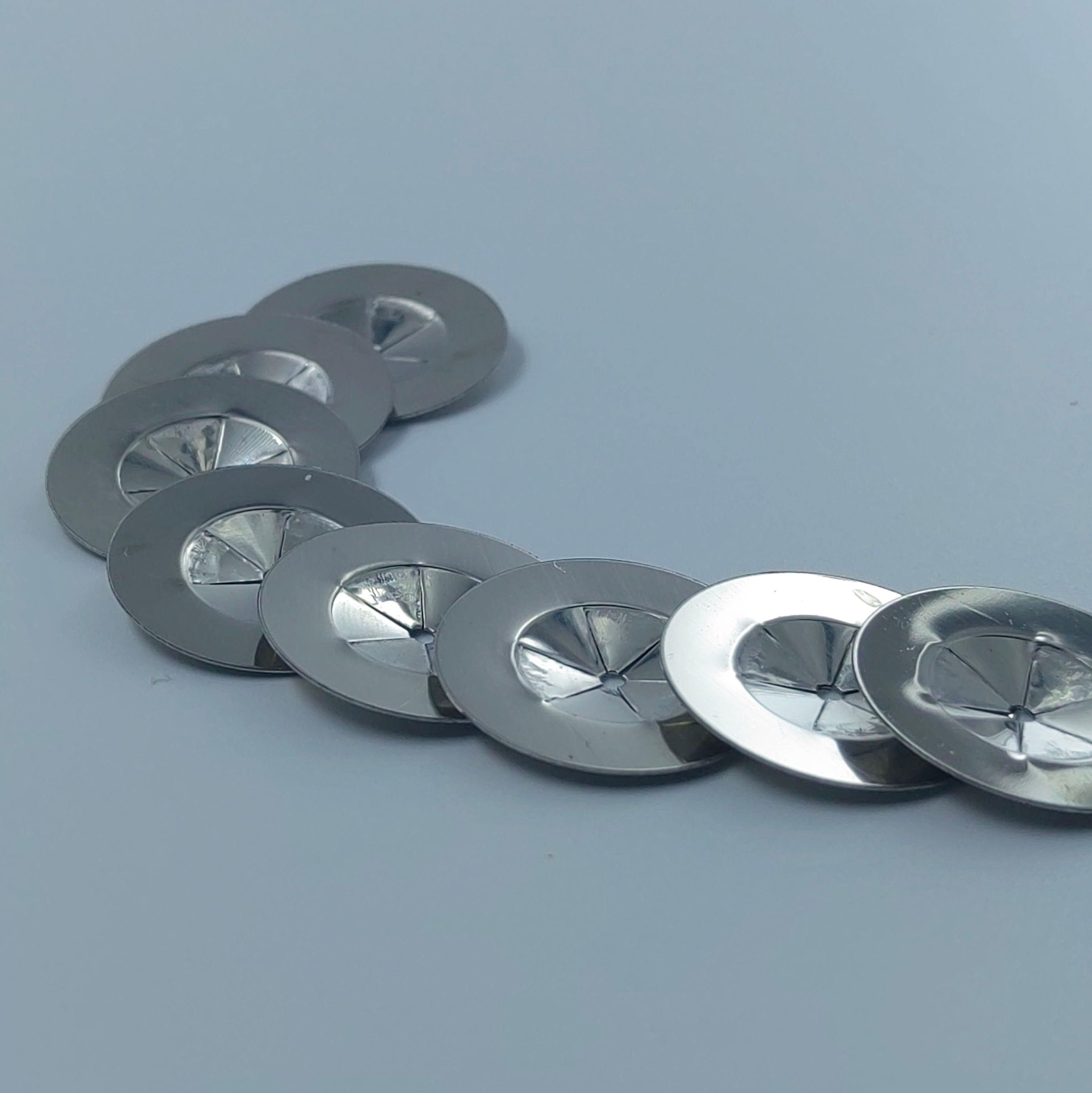

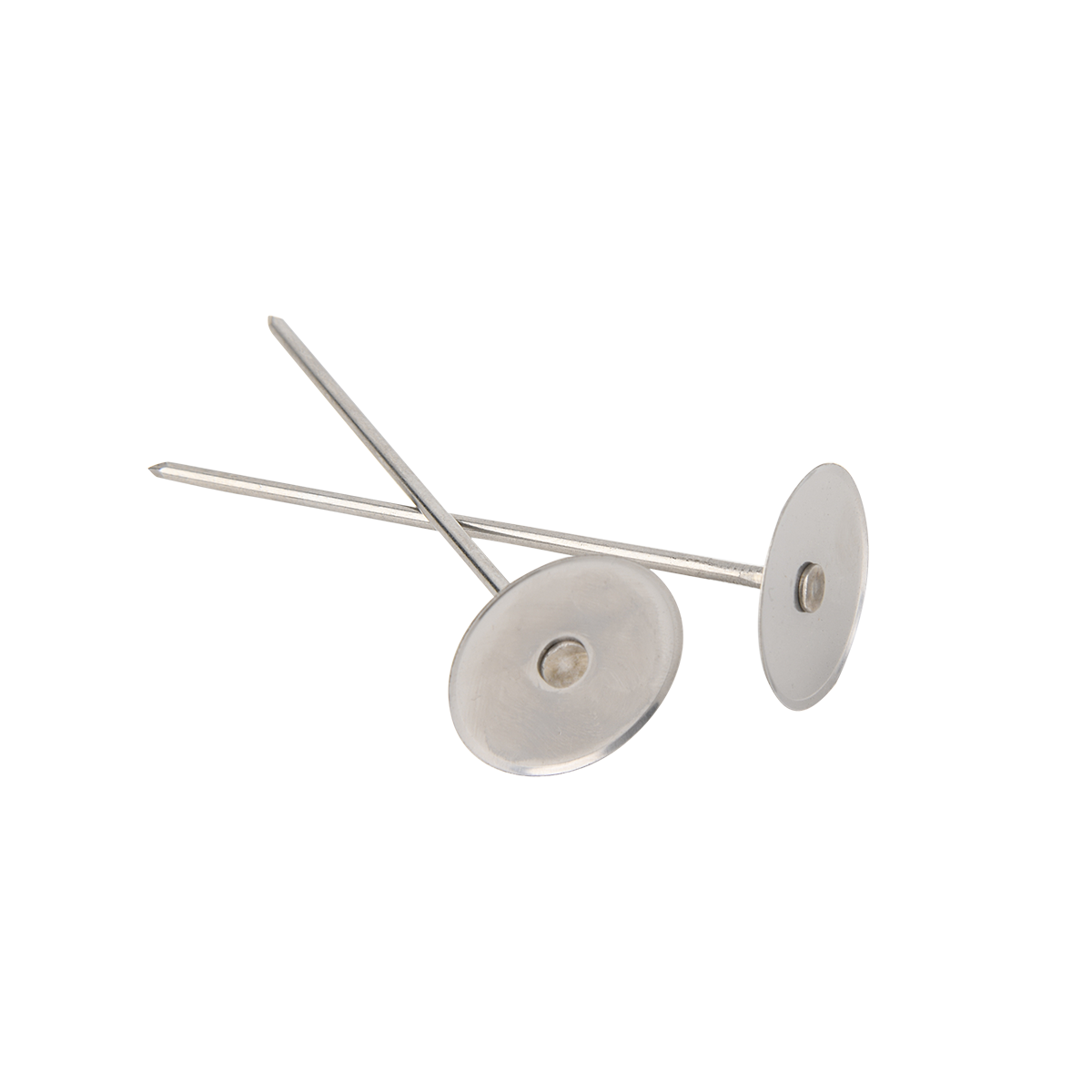

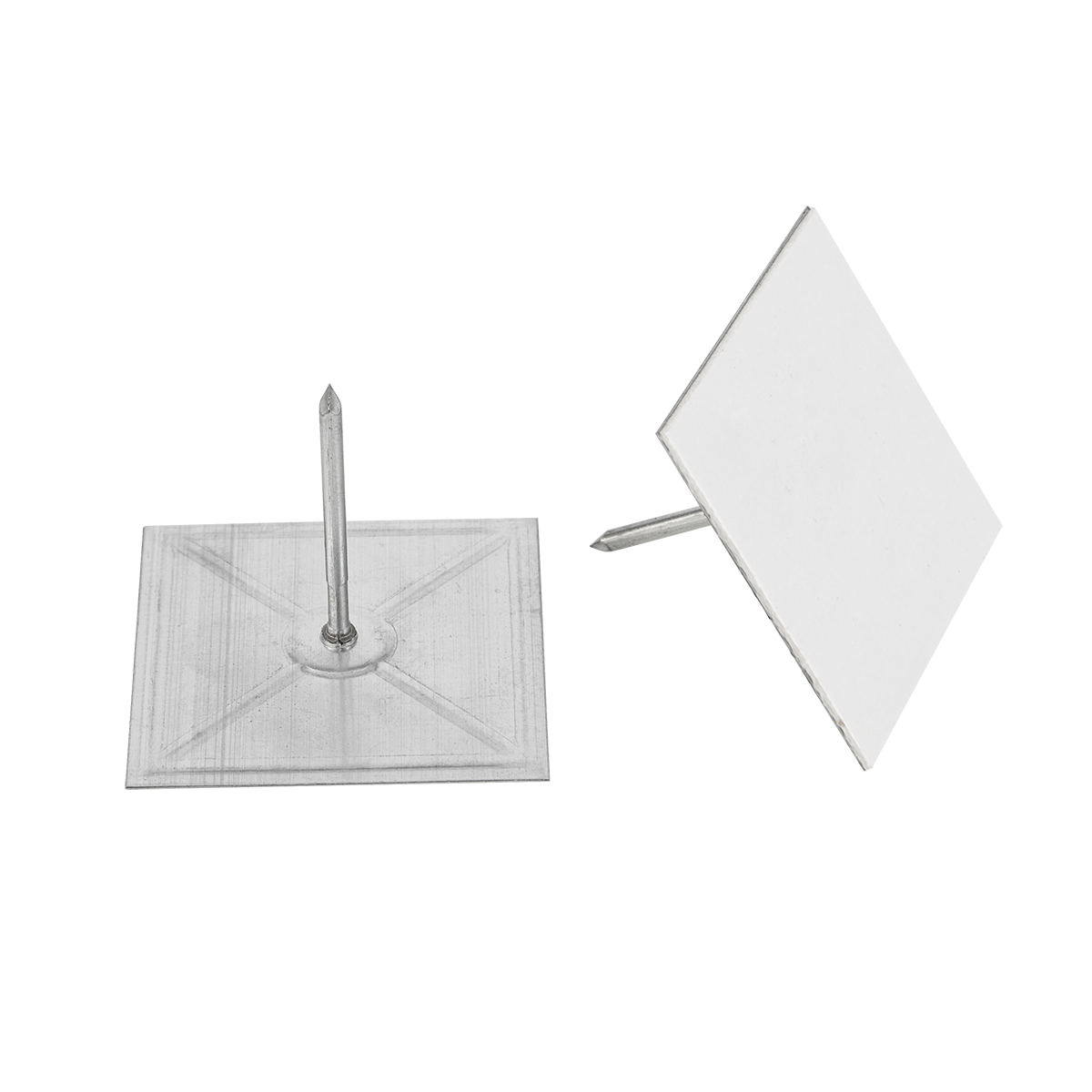

Round Insulation Self Locking Washers

Round insulation self - locking washers are a specialized type of fastener component that combines the properties of insulation and self - locking mechanisms within a circular design. These washers are engineered to meet the demanding requirements of various industries, offering a range of functions that contribute to the safety, reliability, and efficiency of mechanical and electrical systems.

Contact

Product Detail

Round insulation self - locking washers are a specialized type of fastener component that combines the properties of insulation and self - locking mechanisms within a circular design. These washers are engineered to meet the demanding requirements of various industries, offering a range of functions that contribute to the safety, reliability, and efficiency of mechanical and electrical systems.

1. Design and Structure

The round shape of these washers is not just a matter of aesthetics; it is a design choice that optimizes their performance in multiple ways. The circular form provides a uniform distribution of forces around the fastener, whether it is a bolt, screw, or nut. This uniform force distribution is crucial for maintaining the integrity of the joint, especially in applications where the load is applied symmetrically.

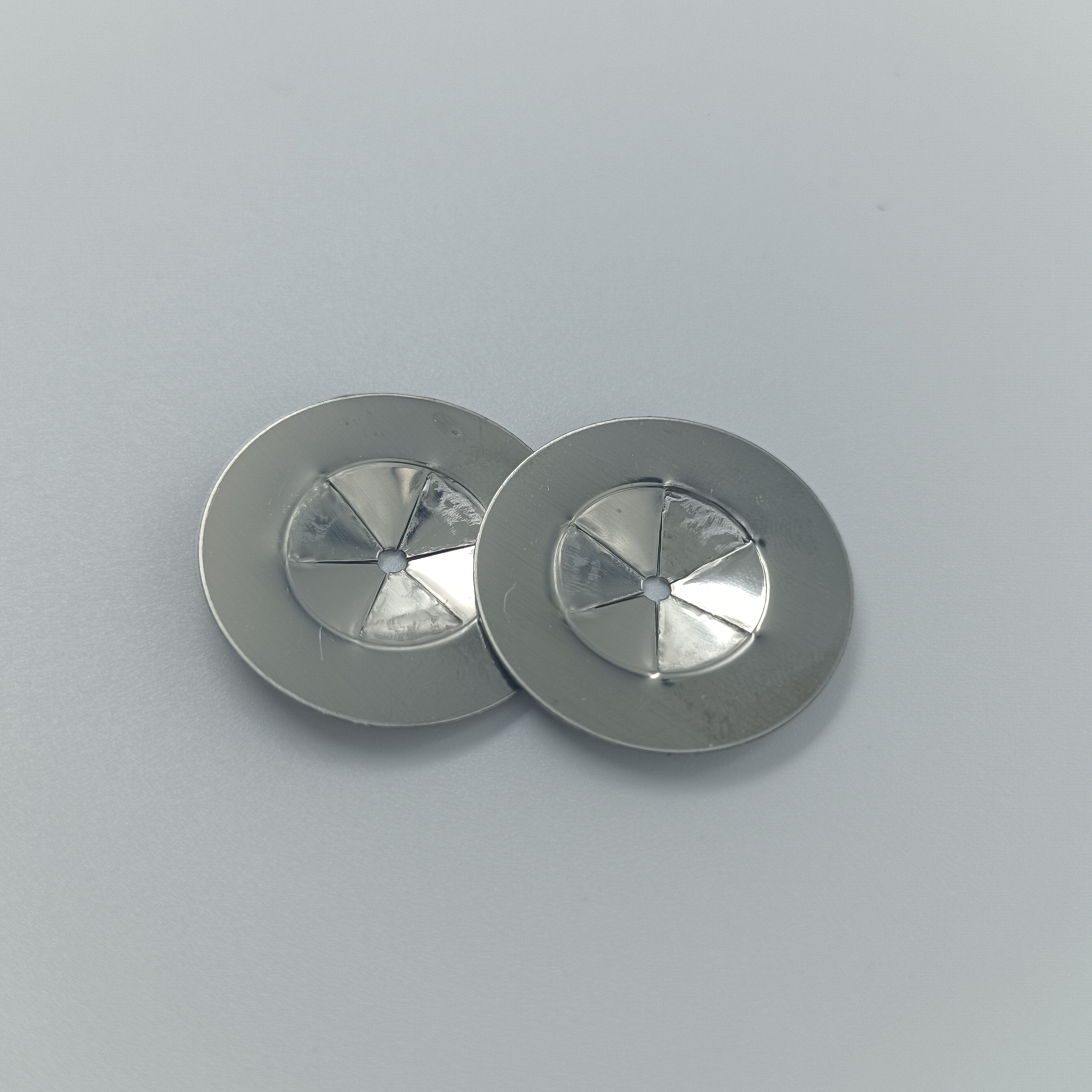

Typically, round insulation self - locking washers are made from high - quality insulating materials such as reinforced plastics or elastomers. These materials are chosen for their excellent dielectric properties, which are essential for providing electrical insulation. The self - locking feature is often achieved through a serrated or toothed design on one or both sides of the washer. The teeth are carefully angled and sized to create a strong frictional grip when the fastener is tightened. This grip effectively resists the loosening forces caused by vibrations, dynamic loads, and temperature changes.

In some advanced designs, the round insulation self - locking washers may also incorporate additional features. For example, there could be a raised inner diameter or a centered boss that helps with alignment during installation. This ensures that the washer is properly positioned around the fastener, further enhancing its performance.

2. Electrical Insulation Function

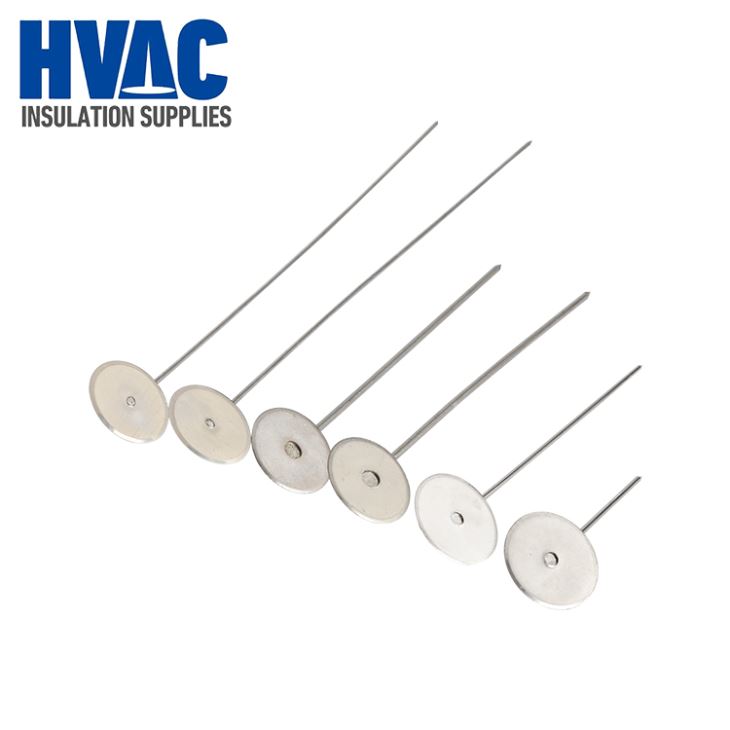

One of the primary functions of round insulation self - locking washers is to provide electrical insulation. In electrical systems, it is essential to prevent the flow of electrical current between different components or between a component and the surrounding structure. These washers act as a reliable barrier, isolating electrical conductors from metal surfaces.

In power distribution systems, round insulation self - locking washers are commonly used to mount electrical equipment such as transformers, circuit breakers, and switchgear. They ensure that the high - voltage components are electrically isolated from the metal enclosures, reducing the risk of electrical short - circuits and protecting personnel from electric shock. In residential and commercial electrical installations, they are used to insulate electrical outlets, switches, and wiring connections. This helps to maintain the safety and integrity of the electrical system, especially in areas where moisture or conductive materials may be present.

In the electronics industry, round insulation self - locking washers are used in printed circuit boards (PCBs) to mount components such as integrated circuits, capacitors, and resistors. They not only provide electrical insulation but also help to secure the components in place, protecting them from mechanical stress and vibration. This is crucial for the proper functioning of electronic devices, as any electrical interference or component displacement can lead to malfunctions.

3. Self - Locking and Anti - Loosening Function

The self - locking feature of round insulation self - locking washers is a key advantage in mechanical applications. In machinery and equipment, vibrations, shocks, and cyclic loads can cause fasteners to gradually loosen over time. This can lead to component misalignment, reduced performance, and even catastrophic failures.

The serrated or toothed surface of the round self - locking washers bites into the mating surfaces of the fastener and the workpiece when tightened. This creates a high - friction interface that resists the loosening forces. For example, in automotive engines, round insulation self - locking washers are used to secure the cylinder head bolts. The constant vibrations and high - temperature variations in the engine can cause the bolts to loosen if not properly secured. The self - locking washers ensure that the bolts remain tight, maintaining the proper compression in the combustion chambers and preventing leaks of oil, coolant, and combustion gases.

In industrial machinery such as pumps, compressors, and conveyors, round insulation self - locking washers are also widely used. These machines often operate under harsh conditions, including high - speed rotations, heavy loads, and vibrations. The self - locking washers help to keep the fasteners in place, reducing the need for frequent maintenance and minimizing the risk of unexpected breakdowns.

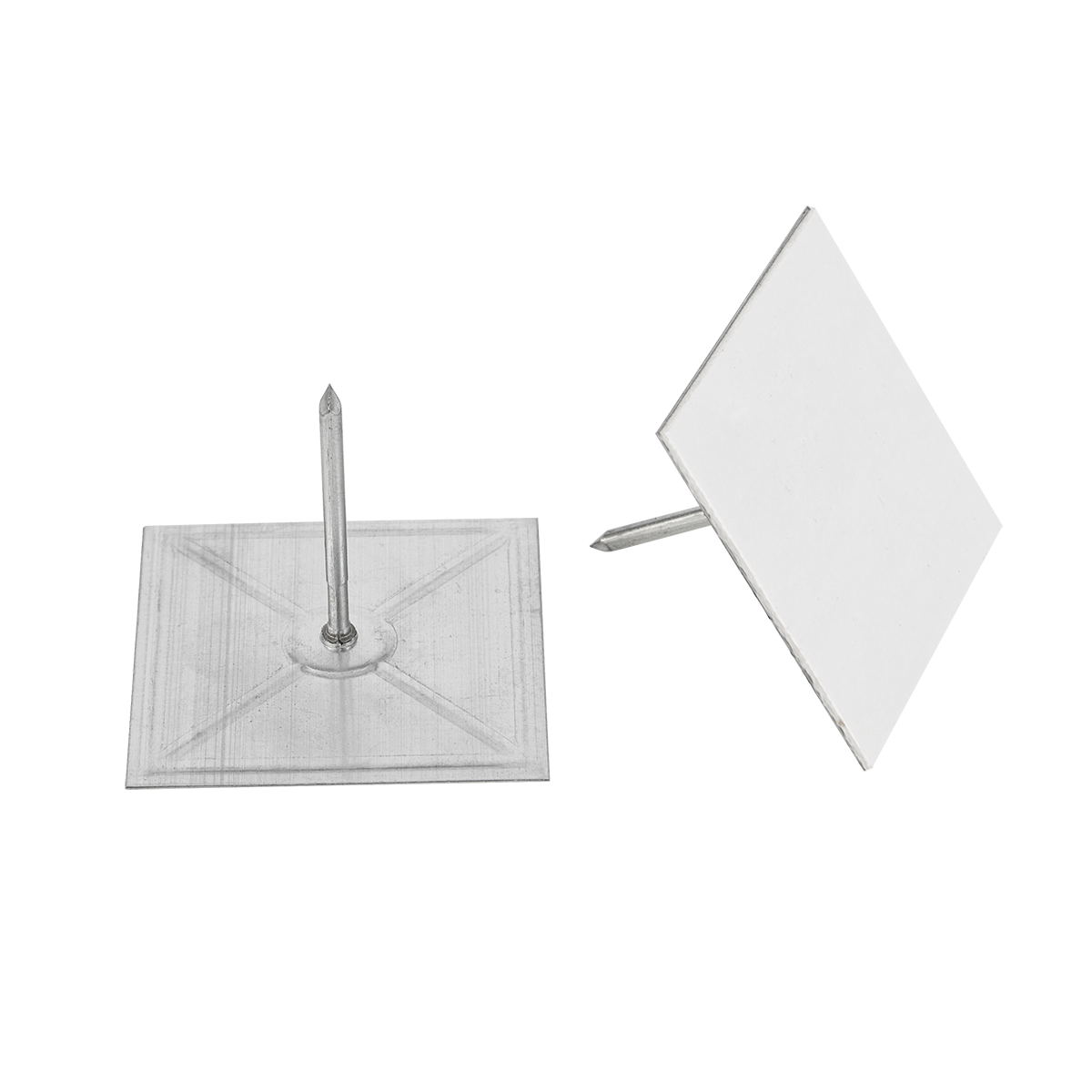

4. Pressure Distribution and Load Bearing

Round insulation self - locking washers are effective in distributing the pressure exerted by the fastener evenly across the surface of the workpiece. When a fastener is tightened, the load is concentrated at the point of contact between the fastener and the workpiece. This can lead to stress concentrations, which may cause the workpiece to deform, crack, or fail prematurely.

The large circular surface area of the round washer helps to spread the load over a wider area. This reduces the stress on the workpiece and improves the overall stability of the joint. In structural applications, such as in the construction of buildings and bridges, round insulation self - locking washers are used to fasten steel components together. They ensure that the load is evenly distributed, preventing local damage to the structural members and enhancing the structural integrity of the entire structure.

In the aerospace industry, where weight - saving is a critical factor, the use of round insulation self - locking washers allows for the use of thinner and lighter materials without sacrificing strength. By distributing the pressure effectively, these washers enable the design of more efficient and reliable structures.

5. Environmental Resistance and Durability

Round insulation self - locking washers are designed to withstand a variety of environmental conditions. The insulating materials used in their construction are often resistant to moisture, chemicals, and temperature variations. This makes them suitable for use in harsh environments, such as in the chemical processing industry, marine applications, and outdoor electrical installations.

In the chemical processing industry, where the washers may be exposed to corrosive chemicals, the use of chemical - resistant insulating materials ensures that the washers do not degrade over time. In marine applications, the washers are exposed to saltwater, high humidity, and constant vibrations. Their corrosion - resistant properties and self - locking features make them ideal for securing components in boats, ships, and offshore structures.

In outdoor electrical installations, round insulation self - locking washers are exposed to sunlight, rain, snow, and temperature fluctuations. The materials used in their construction are often UV - resistant and have a high thermal stability, ensuring that the washers maintain their performance over an extended period. This reduces the need for frequent replacement and maintenance, making them a cost - effective solution.

6. Installation and Maintenance Considerations

Proper installation of round insulation self - locking washers is crucial for their optimal performance. During installation, it is important to ensure that the washer is clean and free from any debris. The fastener should be tightened to the recommended torque value to ensure that the self - locking mechanism engages properly. If the fastener is over - tightened, it may damage the washer or the workpiece. If it is under - tightened, the self - locking feature may not be effective.

Regular maintenance of round insulation self - locking washers is also important. Periodic inspections should be carried out to check for any signs of wear, damage, or loosening. If any damage is detected, such as cracks in the insulating material or worn - out teeth, the washer should be replaced immediately. In addition, the washers should be cleaned regularly to remove any accumulated dirt, dust, or contaminants. This helps to maintain their performance and extend their lifespan.

round insulation self - locking washers are versatile and essential components in many industries. Their unique combination of electrical insulation, self - locking, pressure distribution, environmental resistance, and durability makes them suitable for a wide range of applications. By understanding their design, functions, and installation and maintenance requirements, engineers and technicians can make informed decisions when selecting and using these washers to ensure the safety, reliability, and efficiency of their systems.