Perforated Insulation Pins Self Locking Washers

Perforated insulation pins self locking washers are highly specialized fastening components that have carved out a significant niche in multiple industries. These washers combine the functions of insulation, secure fastening, and in some cases, additional features related to their perforated design.

Contact

Product Detail

1. Introduction

Perforated insulation pins self locking washers are highly specialized fastening components that have carved out a significant niche in multiple industries. These washers combine the functions of insulation, secure fastening, and in some cases, additional features related to their perforated design. They are designed to address the complex requirements of applications where electrical isolation, vibration resistance, and reliable mechanical connection are crucial. This comprehensive overview will cover their design, working principles, applications, advantages, challenges, and future trends.

2. Design and Structure

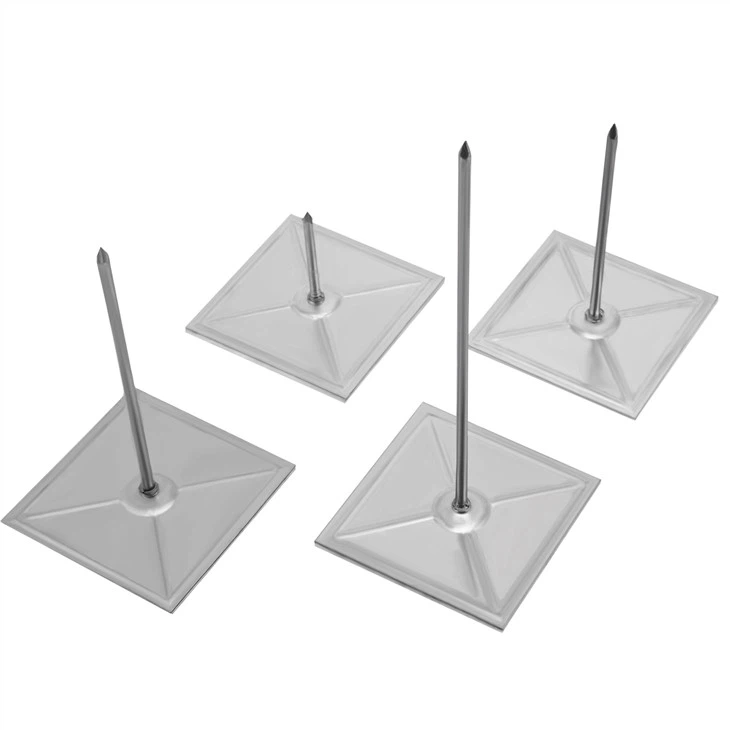

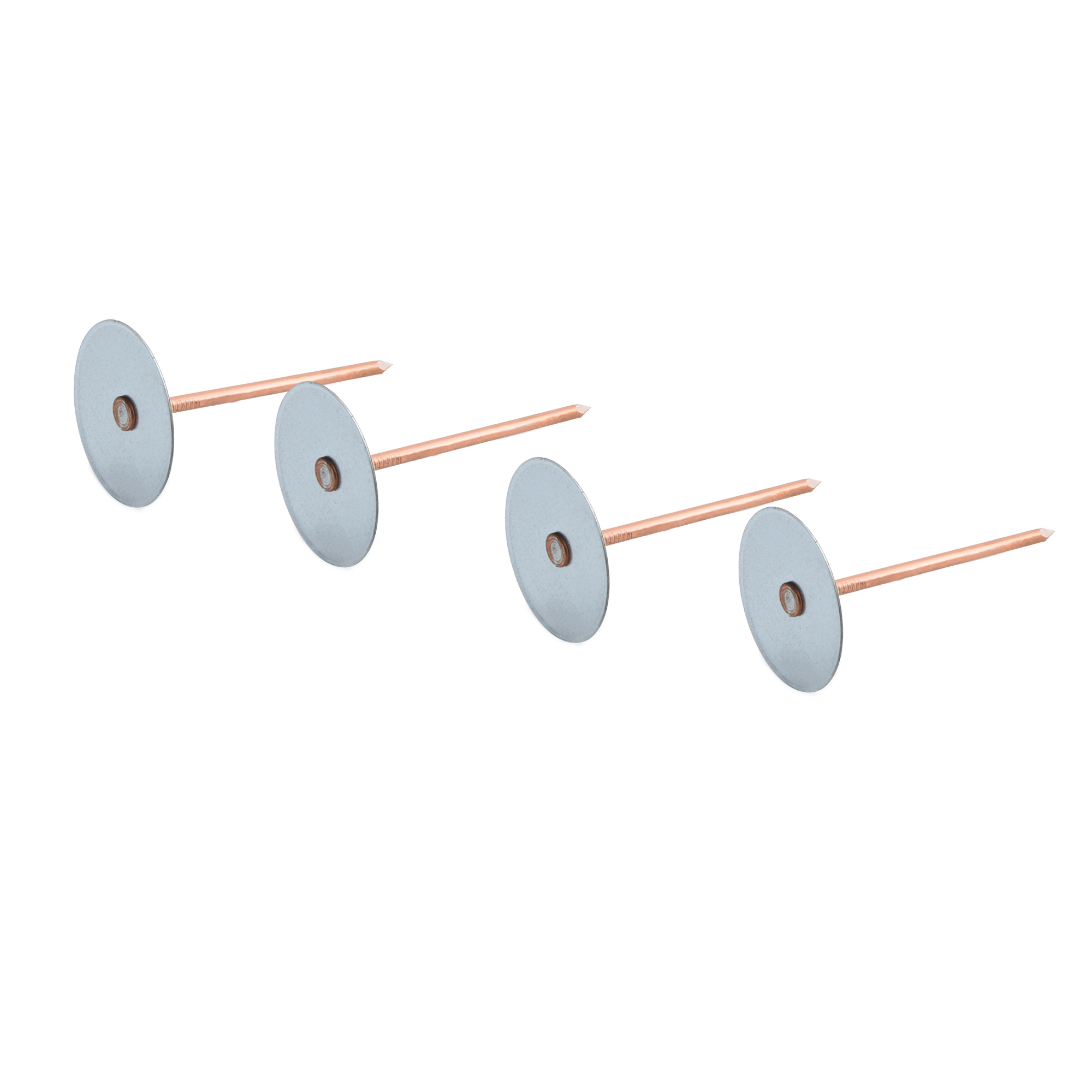

2.1 The Pin Component

The insulation pin at the core of these washers is typically made of a non conductive material. Materials such as high grade plastics like polyetheretherketone (PEEK) or glass filled nylon are commonly used. The pin has a cylindrical shape with a diameter and length tailored to the specific application. One end of the pin is often designed to be inserted into a pre drilled hole in the workpiece, while the other end is where the self locking washer part is attached. The surface of the pin may have grooves or a textured finish to enhance its grip within the hole and prevent rotational movement.

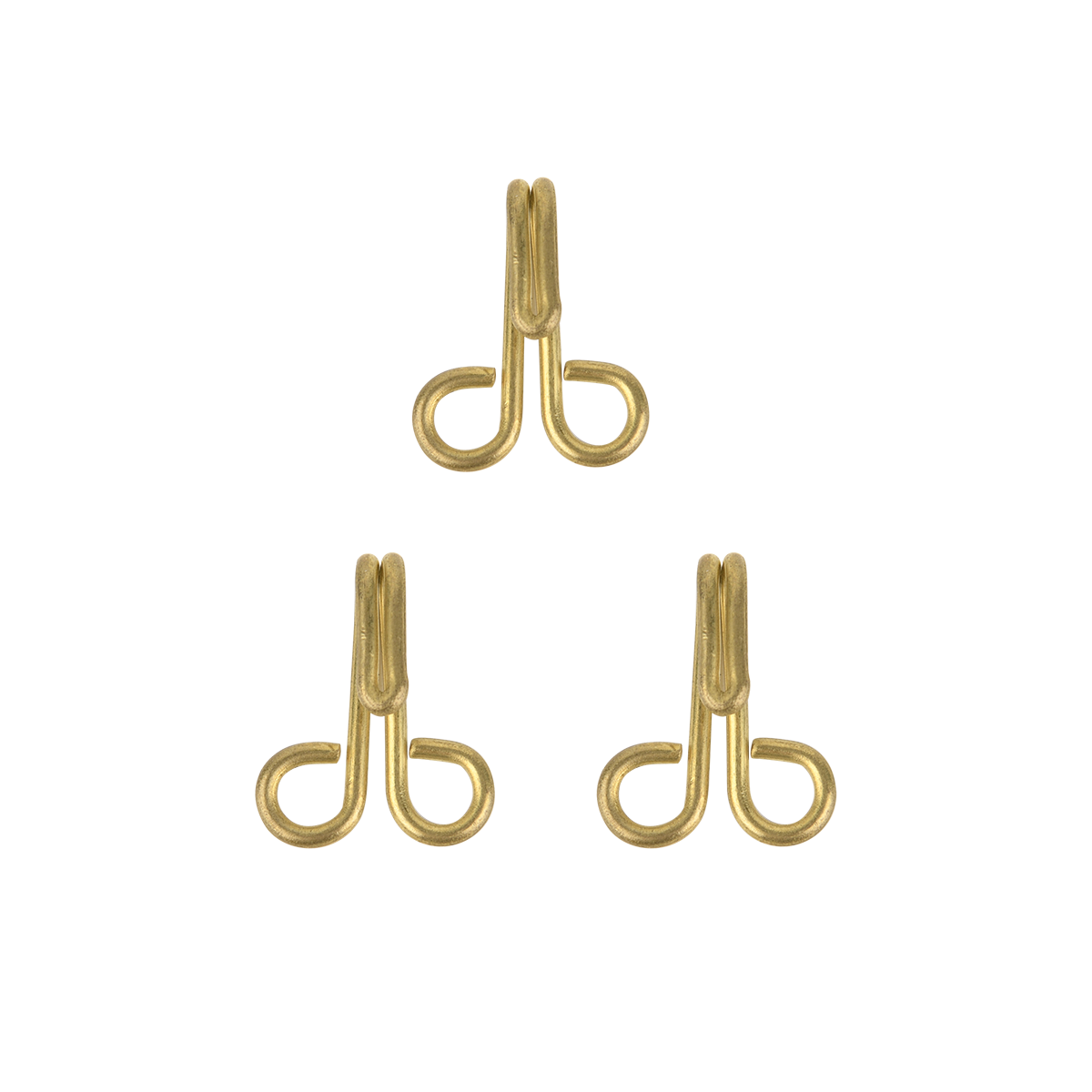

2.2 The Self Locking Washer Part

The self locking washer is an integral part of the assembly. It is usually made of a metal or a composite material with sufficient strength. The washer has a central hole through which the insulation pin passes. Around the central hole, there are self locking features. These can be in the form of radial teeth or serrations. The teeth are angled in a way that when the washer is tightened against the surface of the workpiece, they dig into the material, creating a high friction interface. This friction resists any loosening of the fastener due to vibrations or mechanical stresses.

2.3 Perforations

The perforations in these washers are a distinguishing feature. The holes are carefully designed and distributed across the surface of the washer. Their size, shape, and pattern can vary depending on the application requirements. Perforations can serve multiple purposes. In some cases, they are used to reduce the weight of the washer without sacrificing its structural integrity. They can also enhance the flexibility of the washer, allowing it to conform better to irregular surfaces. Additionally, in certain applications, the perforations may be designed to facilitate the passage of air or fluids, which can be important in heat dissipation or fluid management systems.

3. Working Principles

3.1 Self Locking Mechanism

When the perforated insulation pins self locking washers are installed, the self locking teeth on the washer play a crucial role. As the pin is inserted into the hole in the workpiece and the washer is tightened, the teeth engage with the surface of the workpiece. As the fastener is further tightened, the teeth dig deeper into the material. The angled design of the teeth creates a mechanical wedge like effect. Any force that attempts to rotate the fastener in the loosening direction causes the teeth to be pushed more firmly into the material, increasing the frictional resistance. This self locking mechanism ensures that the fastener remains securely in place, even under harsh operating conditions.

3.2 Insulation Function

The non conductive insulation pin provides electrical isolation. In applications where electrical components are being fastened, the pin acts as a barrier between metal parts. For example, in an electrical panel where metal components need to be secured while preventing electrical current flow between them, the insulation pin ensures that there is no electrical short circuiting. The material of the pin and its design characteristics, such as its thickness and surface finish, are optimized to provide high quality electrical insulation.

3.3 Role of Perforations

The perforations can have an impact on the overall performance of the washer. In applications where flexibility is required, the perforations allow the washer to bend and conform to the shape of the workpiece more easily. This is beneficial when fastening components with irregular surfaces. In terms of heat dissipation, if the application involves heat generating components, the perforations can allow air to flow through, facilitating the transfer of heat away from the fastened area. This can help in maintaining the optimal operating temperature of the components.

4. Applications

4.1 Electrical and Electronic Industries

In the electrical and electronic sectors, perforated insulation pins self locking washers are extensively used. In power generation and distribution systems, they are used to fasten components such as transformers, switchgear, and busbars. The insulation provided by the pins ensures the safe operation of the electrical system by preventing electrical leakage. In electronic devices, such as printed circuit boards (PCBs), these washers are used to secure components like capacitors, resistors, and integrated circuits. The self locking feature ensures that the components remain in place during the manufacturing process and throughout the device's lifespan, even in the presence of vibrations.

4.2 Automotive Industry

The automotive industry also makes significant use of these specialized washers. In the electrical systems of vehicles, they are used to fasten sensors, actuators, and wiring harnesses. The self locking mechanism ensures that these components stay securely fastened, even under the harsh vibrations and mechanical stresses experienced during vehicle operation. In hybrid and electric vehicles, the insulation properties of the pins are crucial for the safe operation of the high voltage electrical systems. The perforations in the washers can also play a role in heat management in automotive applications, as the engine and electrical components generate a significant amount of heat.

4.3 Aerospace Industry

In the aerospace industry, reliability and safety are of utmost importance. Perforated insulation pins self locking washers are used in aircraft for fastening various electrical and mechanical components. In avionics systems, they are used to secure electronic devices, ensuring that they remain in place during flight, where vibrations, temperature changes, and mechanical stresses are extreme. The insulation properties are essential for preventing electrical malfunctions in the aircraft's complex electrical systems. The weight reducing aspect of the perforations is also highly valued in aerospace, as every gram of weight reduction can contribute to improved fuel efficiency.

4.4 Renewable Energy Sector

In the renewable energy sector, such as in wind turbines and solar panel installations, these washers find application. In wind turbines, they are used to fasten electrical components and mechanical parts. The self locking feature ensures that the components remain secure in the face of strong winds and vibrations. The insulation properties are important for protecting the electrical systems from short circuits. In solar panel installations, the washers are used to secure the panels to the mounting structures. The perforations can allow for better ventilation, which helps in maintaining the efficiency of the solar panels by preventing overheating.

5. Advantages

5.1 High Quality Insulation

The use of non conductive insulation pins provides excellent electrical isolation. This is crucial in applications where electrical safety is a top priority. By preventing electrical current from flowing between components, it reduces the risk of electrical accidents, such as short circuits and electrical shocks. In industries like electrical power and electronics, this high quality insulation is essential for the proper functioning and safety of the systems.

5.2 Secure Fastening

The self locking mechanism of the washers ensures a reliable and secure fastening. The teeth on the washer create a high friction connection with the workpiece, which resists loosening due to vibrations, mechanical stress, or temperature changes. This is especially important in applications where components need to remain firmly in place over long periods, such as in automotive and aerospace applications. The secure fastening reduces the need for frequent maintenance and re tightening, saving both time and costs.

5.3 Weight Reduction and Flexibility

The perforations in the washers offer the advantage of weight reduction. In industries where weight is a critical factor, such as aerospace and some automotive applications, this can lead to improved performance and fuel efficiency. Additionally, the perforations enhance the flexibility of the washer, allowing it to adapt to different surface shapes and contours. This makes it suitable for fastening components with irregular surfaces, expanding its range of applications.

5.4 Heat Dissipation and Ventilation

In applications where heat management is important, the perforations in the washers can facilitate heat dissipation. By allowing air or fluids to flow through, they help in reducing the temperature of the fastened components. This is beneficial in industries such as electronics, automotive, and renewable energy, where overheating can lead to component failure and reduced efficiency.

6. Challenges and Solutions

6.1 Material Selection and Compatibility

Selecting the right materials for the insulation pins and the self locking washers is a challenge. The insulation material must have excellent electrical properties, mechanical strength, and resistance to environmental factors. At the same time, the material of the washer should be compatible with the insulation pin and the workpiece. To address this, manufacturers conduct extensive material testing and research. They offer a variety of material options, allowing engineers to choose the most suitable combination for their specific application. For example, different grades of plastics for the insulation pins and corrosion resistant metals for the washers can be selected based on the operating environment.

6.2 Installation and Torque Requirements

Determining the correct installation torque for perforated insulation pins self locking washers is crucial. If the torque is too low, the self locking mechanism may not engage properly, and the fastener may loosen. On the other hand, if the torque is too high, it can damage the insulation pin or the workpiece. To solve this problem, manufacturers provide detailed installation guidelines that specify the recommended torque values for different applications. In addition, torque controlled fastening tools are often used to ensure accurate installation. These tools can precisely control the amount of torque applied, reducing the risk of under or over tightening.

6.3 Durability in Harsh Environments

In harsh environments, such as those with high temperatures, humidity, or corrosive substances, the durability of the washers can be a concern. The insulation material may degrade over time, and the self locking mechanism may be affected. To enhance durability, manufacturers develop materials with improved resistance to environmental factors. For example, they may use materials with enhanced heat resistance or corrosion resistant coatings on the washers. Regular maintenance and inspection procedures are also recommended to ensure the continued performance of the washers in harsh environments.

7. Future Trends

7.1 Development of Advanced Materials

The future is likely to see the development of even more advanced materials for perforated insulation pins self locking washers. These materials may have enhanced electrical insulation properties, higher mechanical strength, and improved resistance to extreme environmental conditions. For example, nanocomposite materials could be used, which combine the unique properties of nanomaterials with traditional insulation and structural materials. These advanced materials would enable the washers to perform better in high performance applications, such as in next generation aerospace and high power electrical systems.

7.2 Integration of Smart Features

There is a growing trend towards integrating smart features into fastening components. In the case of perforated insulation pins self locking washers, this could involve the addition of sensors. These sensors could monitor parameters such as the tightness of the fastener, the integrity of the insulation, and the temperature of the fastened area. The data collected by the sensors could be transmitted wirelessly to a monitoring system, allowing for real time monitoring and predictive maintenance. This would further improve the reliability and safety of the systems in which these washers are used.

7.3 Optimization of Perforation Design

The design of the perforations in the washers is likely to be further optimized in the future. Computational modeling and simulation techniques will be used to design perforation patterns that maximize the benefits of weight reduction, flexibility, heat dissipation, and ventilation while maintaining the structural integrity of the washers. This will lead to more efficient and effective use of these washers in a wide range of applications.

In conclusion, perforated insulation pins self locking washers are versatile and essential fastening components in modern engineering. Their unique combination of insulation, self locking, and perforation related features makes them suitable for a diverse range of applications across multiple industries. As technology advances, these washers will continue to evolve, meeting the increasingly demanding requirements of various sectors for reliable, safe, and high performance fastening solutions.