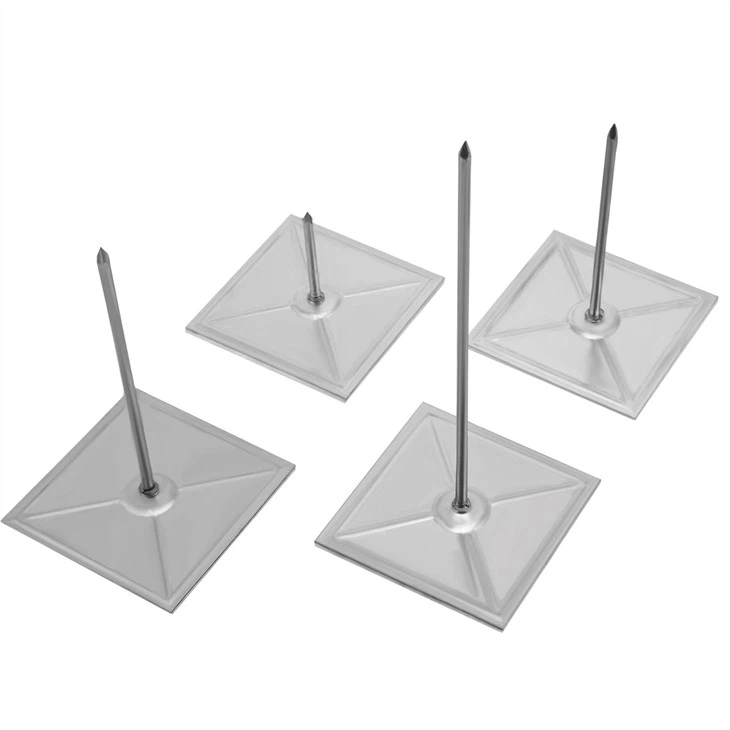

Insulation Pins with Self-Locking Washers

In the realm of mechanical and electrical engineering, the secure and reliable isolation of components is a critical requirement across industries, from automotive manufacturing to aerospace, electronics, and renewable energy systems. Insulation pins, often paired with self-locking washers, represent a sophisticated solution designed to address challenges related to vibration resistance, electrical isolation, and structural integrity. This comprehensive technical exploration delves into the design, functionality, applications, and advantages of insulation pins with self-locking washers, highlighting their role in modern engineering.

Contact

Product Detail

In the realm of mechanical and electrical engineering, the secure and reliable isolation of components is a critical requirement across industries, from automotive manufacturing to aerospace, electronics, and renewable energy systems. Insulation pins, often paired with self-locking washers, represent a sophisticated solution designed to address challenges related to vibration resistance, electrical isolation, and structural integrity. This comprehensive technical exploration delves into the design, functionality, applications, and advantages of insulation pins with self-locking washers, highlighting their role in modern engineering.

1. Understanding Insulation Pins

1.1 Definition and Purpose

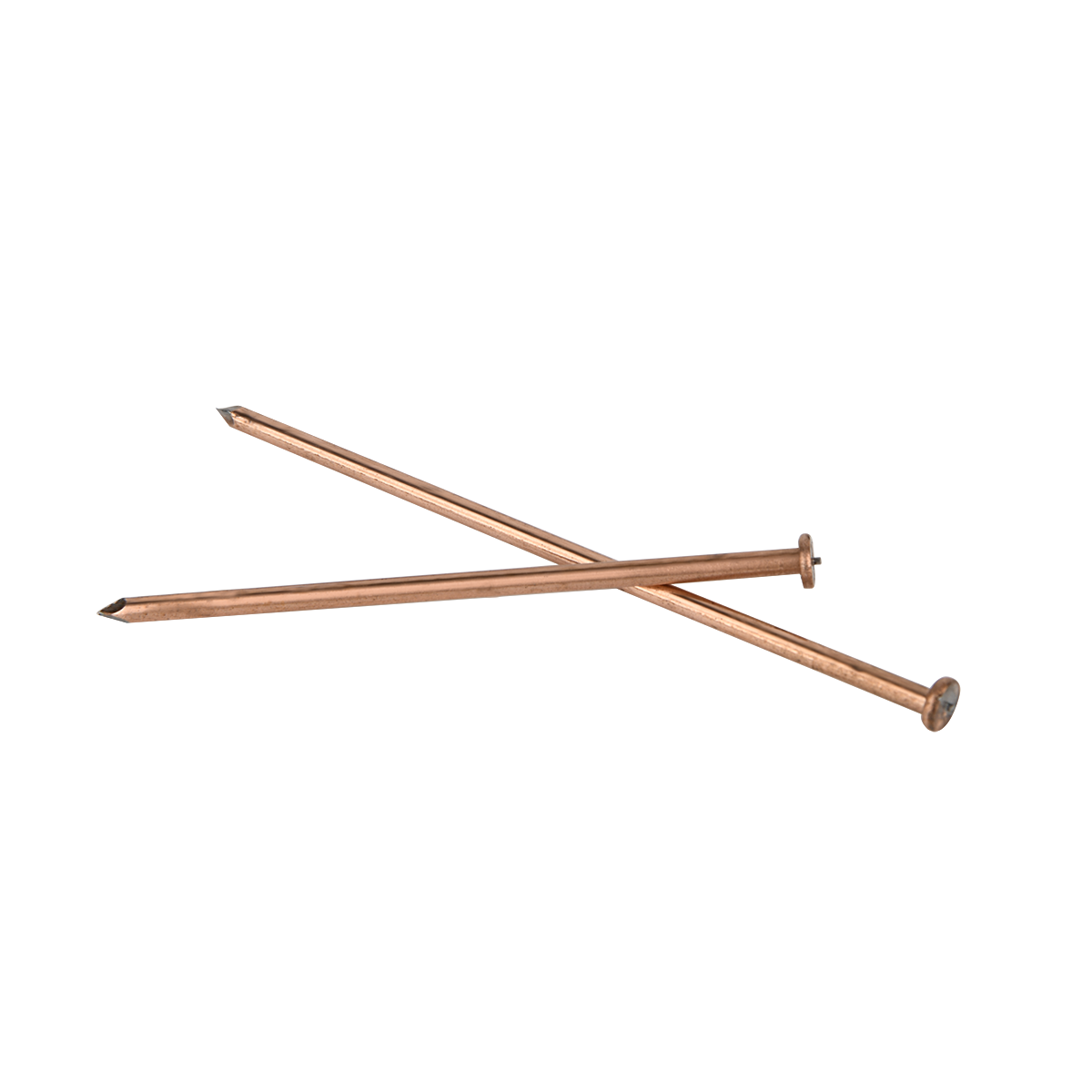

Insulation pins, also known as insulating fasteners or standoffs, are mechanical devices used to physically separate two conductive surfaces while maintaining electrical isolation. They are typically cylindrical or threaded rods made from non-conductive materials such as nylon, PTFE (Teflon), fiberglass-reinforced plastics, or ceramic composites. Their primary functions include:

Electrical Isolation: Preventing current flow between adjacent components.

Mechanical Support: Providing structural stability and spacing.

Vibration Damping: Reducing resonance and mechanical stress in dynamic systems.

1.2 Key Materials

The choice of material for insulation pins depends on the operational environment:

Nylon: Cost-effective, lightweight, and resistant to chemicals.

PTFE: Offers high-temperature resistance and low friction.

Fiberglass-Reinforced Plastics: Balances strength and electrical insulation.

Ceramic: Ideal for high-temperature and high-voltage applications.

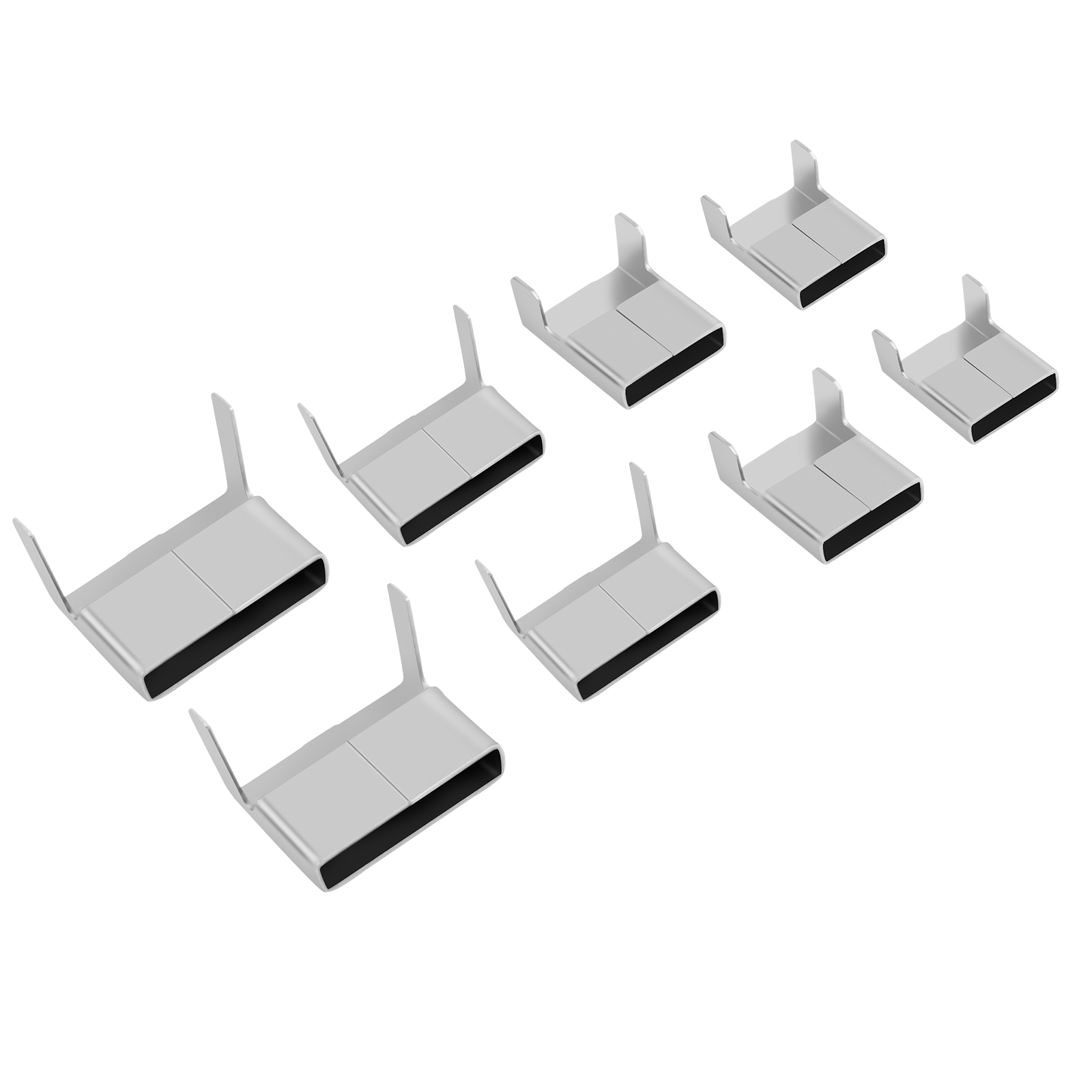

2. Self-Locking Washers: A Critical Complement

2.1 Functionality

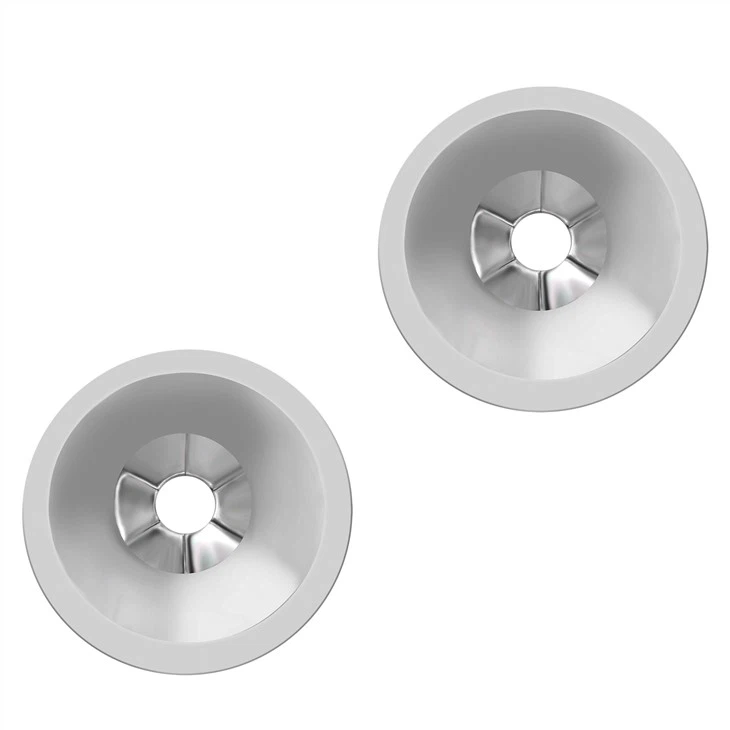

Self-locking washers are integral components designed to prevent fasteners from loosening under dynamic loads, such as vibrations or thermal expansion. Unlike traditional flat washers, they feature teeth, serrations, or spring-like mechanisms that interlock with the mating surface, creating friction and resistance to rotational movement.

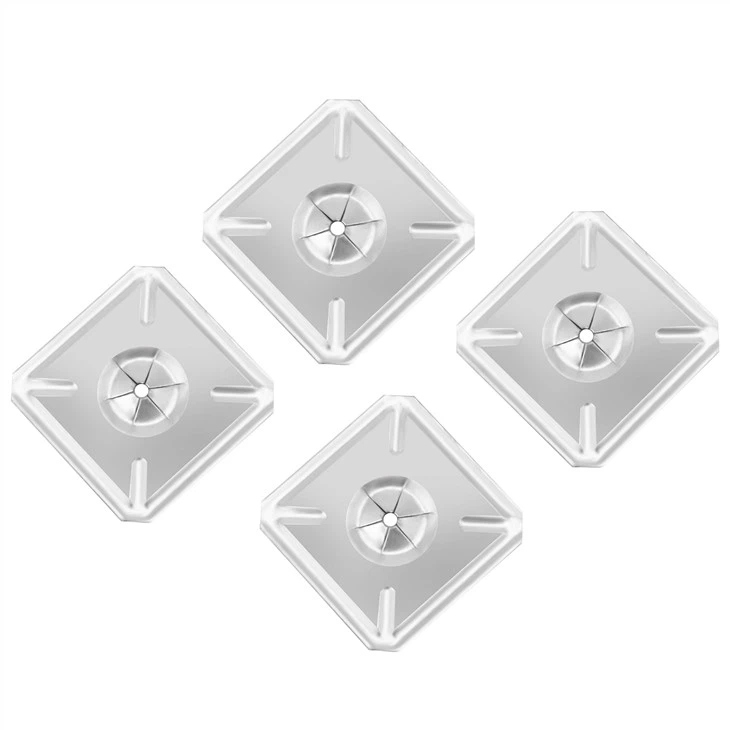

2.2 Types of Self-Locking Washers

Toothed Lock Washers: Radial or tangential teeth bite into the material to prevent loosening.

Spring Lock Washers: Split-ring design creates tension between the nut and the surface.

Nylon-Insert Lock Nuts: A nylon ring inside the nut provides friction to resist back-off.

2.3 Advantages Over Traditional Washers

Superior Vibration Resistance: Maintain clamping force in high-vibration environments.

Reusability: Many self-locking washers can be reused without loss of effectiveness.

Space Efficiency: Compact design reduces overall assembly size.

3. The Synergy: Insulation Pins with Self-Locking Washers

3.1 Design Integration

When combined, insulation pins and self-locking washers create a robust system that addresses two core challenges:

1. Electrical Isolation: The pin ensures no conductive path between components.

2. Mechanical Security: The washer prevents loosening, even under extreme conditions.

3.2 Working Principle

The insulation pin is inserted through aligned holes in the components to be separated.

A self-locking washer is placed over the pin’s threaded end, followed by a nut or another fastener.

The washer’s teeth or serrations grip the mating surface, creating friction that resists rotational forces.

This combination ensures the assembly remains secure while maintaining electrical isolation.

4. Applications Across Industries

4.1 Automotive Engineering

Battery Packs: Insulation pins with self-locking washers secure battery cells, preventing short circuits and ensuring structural integrity during vehicle motion.

ECU Mounting: Isolate electronic control units from metal brackets to avoid EMI interference.

4.2 Aerospace and Defense

Aircraft Wiring: Secure wiring harnesses in high-vibration environments, such as engine compartments.

Composite Structures: Fasten non-metallic components in lightweight airframes.

4.3 Electronics and Telecommunications

PCB Mounting: Standoffs with self-locking features secure circuit boards in enclosures.

HVAC Systems: Isolate electrical components in heating and cooling units.

4.4 Renewable Energy

Solar Panel Mounting: Secure panels to frames while preventing galvanic corrosion.

Wind Turbines: Maintain isolation in generator systems subject to extreme vibrations.

5. Advantages of the Combined System

5.1 Enhanced Safety

Electrical isolation reduces the risk of short circuits and personnel触电.

Mechanical stability prevents component failure in critical systems.

5.2 Cost Efficiency

Eliminates the need for additional anti-loosening devices (e.g., thread-locking compounds).

Long service life reduces maintenance and replacement costs.

5.3 Design Flexibility

Available in various sizes, materials, and configurations to suit diverse applications.

Compatible with automated assembly processes.

6. Installation and Best Practices

6.1 Selection Criteria

Material Compatibility: Ensure the pin and washer materials resist environmental factors (e.g., chemicals, moisture).

Load Requirements: Calculate the clamping force needed to prevent loosening.

Temperature Range: Choose materials suitable for operational temperatures.

6.2 Installation Steps

1. Clean the mating surfaces to remove debris.

2. Align the insulation pin through the components.

3. Place the self-locking washer over the pin’s threaded end.

4. Tighten the nut to the specified torque using a calibrated tool.

6.3 Torque Considerations

Over-tightening can damage the pin or washer.

Under-tightening may result in insufficient clamping force.

7. Testing and Standards

7.1 Performance Testing

Vibration Tests: ASTM D4678 or ISO 16750 for automotive applications.

Dielectric Strength Tests: IEC 60243-1 to measure electrical isolation.

Thermal Cycling Tests: Ensure stability across temperature extremes.

7.2 Industry Standards

RoHS Compliance: Restriction of hazardous substances in electrical components.

UL Certification: Safety testing for electrical equipment.

8. Challenges and Innovations

8.1 Current Limitations

High-Temperature Applications: Some plastics may degrade at elevated temperatures.

Corrosion Resistance: Metal parts in the washer may require coatings (e.g., zinc plating).

8.2 Emerging Trends

Advanced Materials: Development of high-temperature ceramics and composite plastics.

Smart Coatings: Self-healing or anti-corrosion coatings for extended durability.

3D-Printed Components: Custom-designed pins and washers for niche applications.

9. Market Outlook

The global market for insulation pins and self-locking washers is projected to grow at a CAGR of 5.8% from 2023 to 2030, driven by increasing demand in electric vehicles, renewable energy, and industrial automation. Key players include Würth Group, Stanley Black & Decker, and ITW Fasteners.

Insulation pins with self-locking washers exemplify the marriage of mechanical and electrical engineering, offering a versatile solution for secure and efficient component isolation. Their ability to withstand vibrations, maintain electrical integrity, and simplify assembly processes makes them indispensable in modern industries. As technology evolves, these components will continue to adapt, leveraging advanced materials and design innovations to meet future challenges.