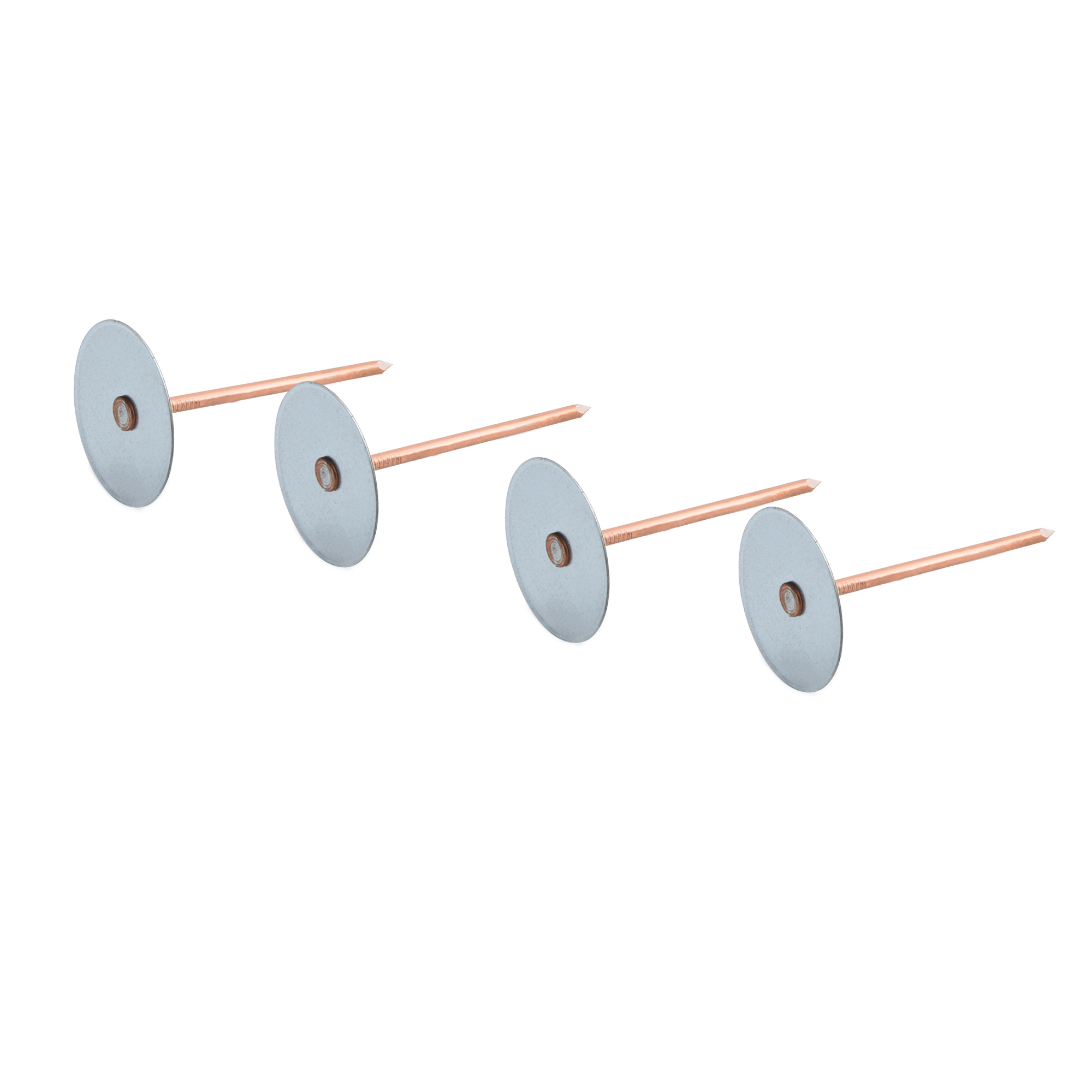

Impaling Pins for Insulation

</h2>Insulation is a crucial aspect of building construction and energy efficiency. It helps to regu

Contact

Product Detail

Insulation is a crucial aspect of building construction and energy efficiency. It helps to regulate temperature, reduce noise, and lower energy consumption. Impaling pins for insulation are a specialized type of fastener that plays an important role in ensuring the proper installation and effectiveness of insulation materials. In this comprehensive guide, we will explore the various aspects of impaling pins for insulation, including their types, features, applications, installation methods, and maintenance.

I. Introduction

Impaling pins for insulation are designed to secure insulation materials in place by piercing through the insulation and into the underlying substrate. These pins provide a reliable and durable fastening solution that helps to prevent insulation from sagging, shifting, or becoming dislodged over time. Impaling pins are available in a variety of materials, sizes, and styles to meet the specific needs of different insulation applications.

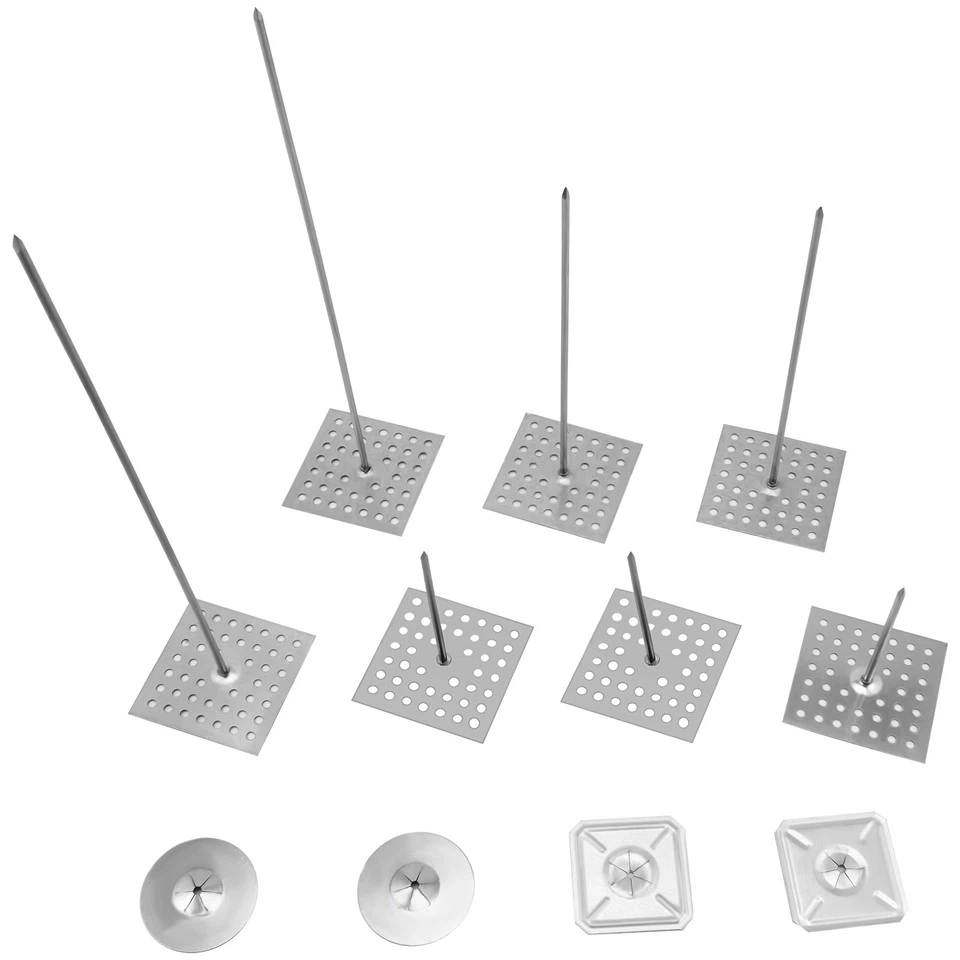

II. Types of Impaling Pins for Insulation

A. Plastic Impaling Pins

Plastic impaling pins are a popular choice for insulation applications due to their lightweight, corrosion-resistant, and cost-effective nature. These pins are typically made from high-quality plastics such as nylon or polypropylene, which offer good insulation properties and are resistant to moisture and chemicals. Plastic impaling pins are available in different lengths and diameters to accommodate various insulation thicknesses and installation requirements.

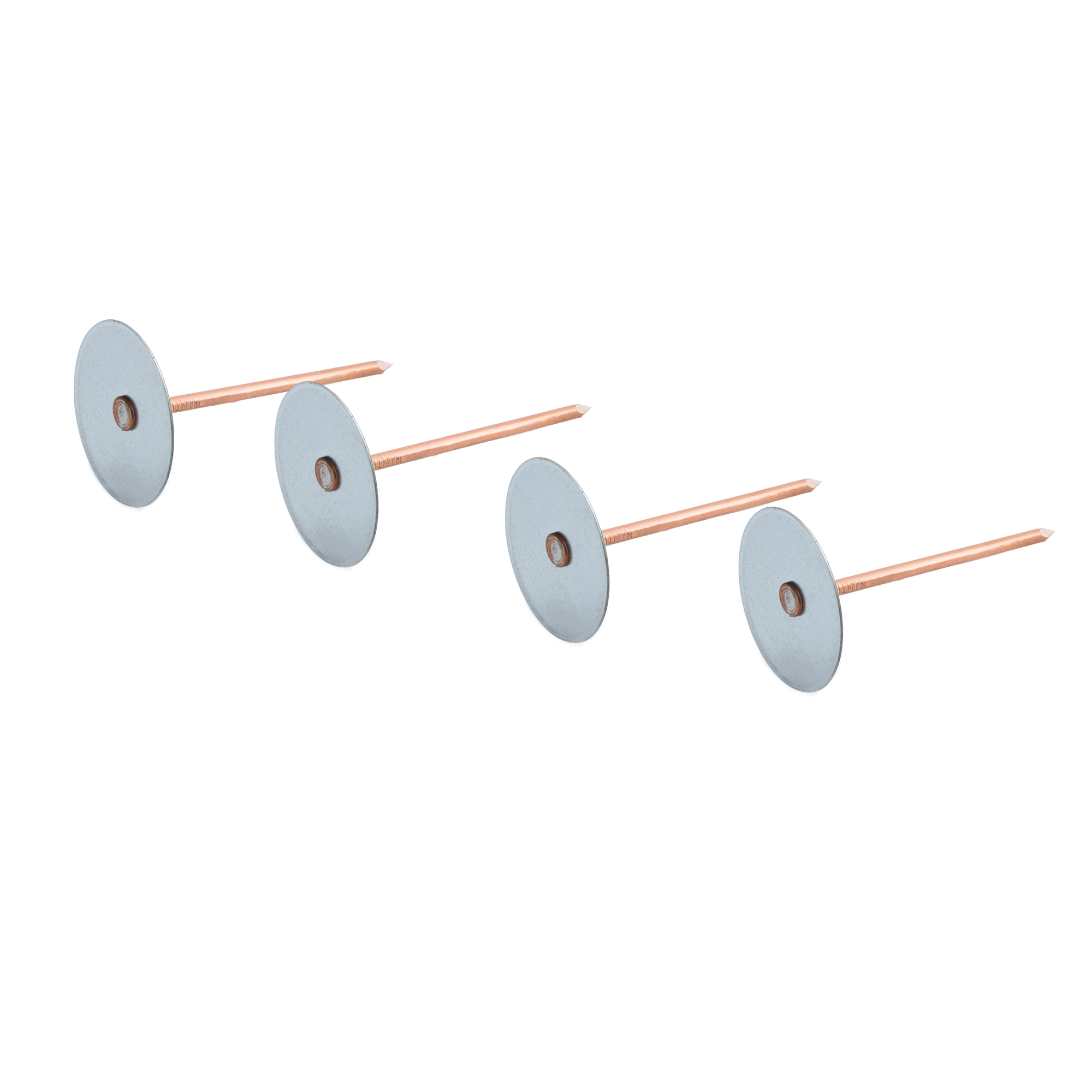

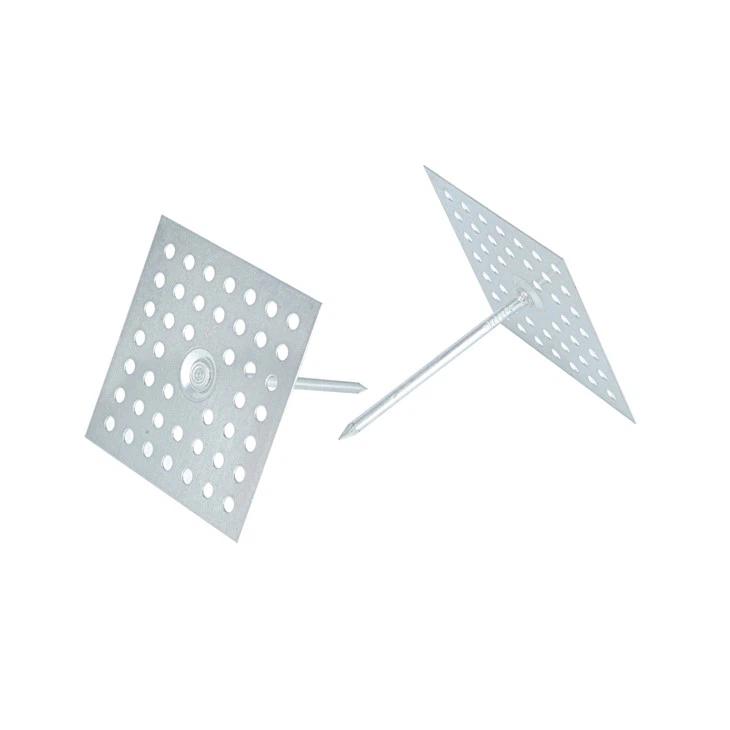

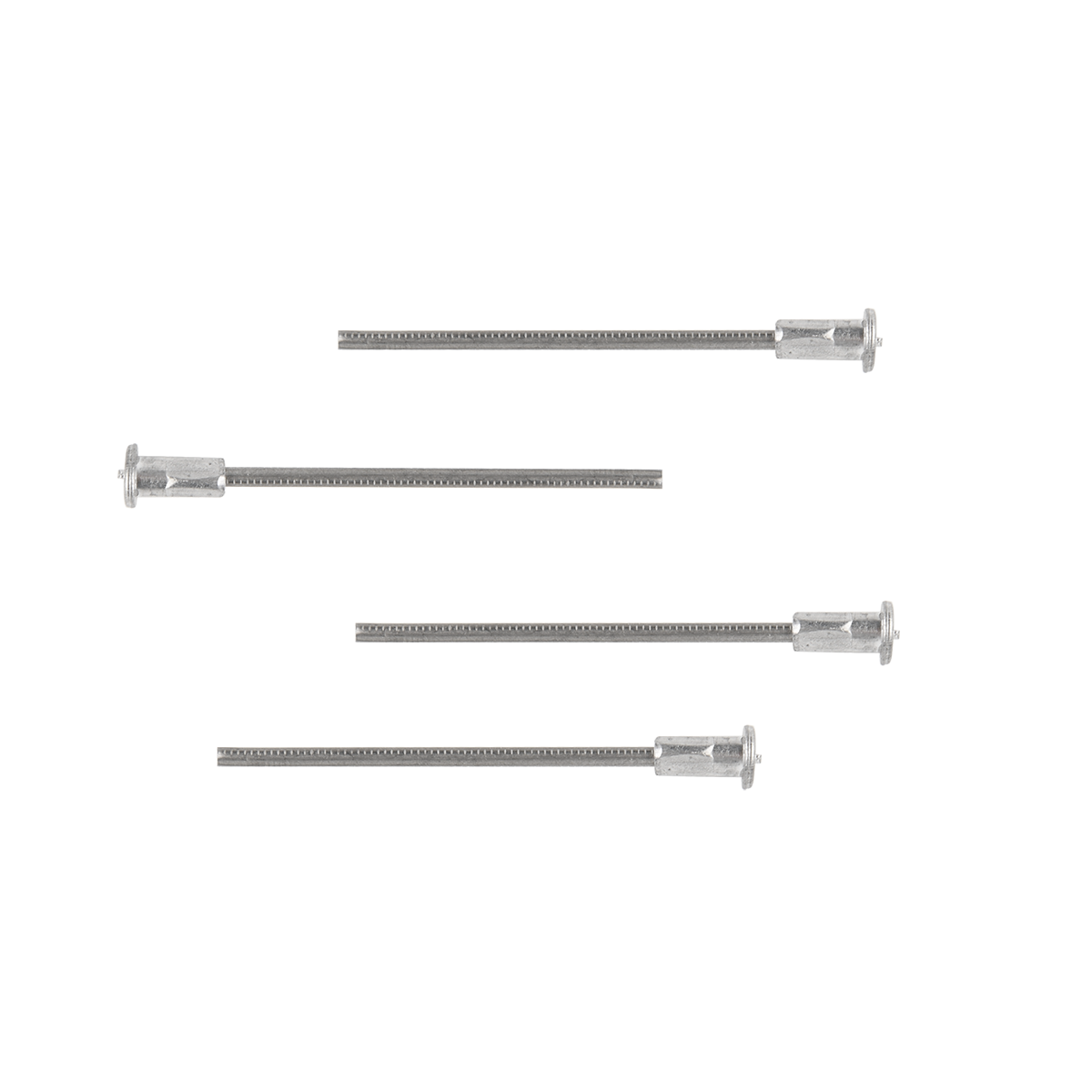

B. Metal Impaling Pins

Metal impaling pins are known for their strength and durability. They are typically made from stainless steel or galvanized steel, which provides excellent corrosion resistance and can withstand heavy loads. Metal impaling pins are suitable for applications where greater strength and stability are required, such as in industrial settings or for insulating heavy-duty equipment. These pins are available in different sizes and styles, including flat-head, round-head, and self-drilling options.

C. Hybrid Impaling Pins

Hybrid impaling pins combine the benefits of both plastic and metal materials. These pins may have a plastic body with a metal tip or a metal shaft with a plastic coating. Hybrid impaling pins offer a balance between strength and insulation properties, making them suitable for a wide range of insulation applications. They are often used in situations where both durability and electrical isolation are important.

III. Features of Impaling Pins for Insulation

A. Secure Attachment

Impaling pins provide a secure attachment for insulation materials by piercing through the insulation and into the underlying substrate. This helps to prevent insulation from sagging, shifting, or becoming dislodged, ensuring long-term stability and effectiveness.

B. Easy Installation

Impaling pins are relatively easy to install, requiring only a hammer or a power tool for insertion. They can be quickly and efficiently installed, saving time and labor costs compared to other fastening methods.

C. Versatility

Impaling pins are available in a variety of materials, sizes, and styles, making them suitable for different types of insulation materials and installation requirements. They can be used in both residential and commercial applications, as well as in industrial settings.

D. Weather Resistance

Many impaling pins are designed to be weather-resistant, able to withstand exposure to moisture, temperature changes, and UV radiation. This makes them suitable for outdoor applications and helps to ensure long-term durability.

E. Cost-Effective

Impaling pins are a cost-effective fastening solution for insulation applications. They are relatively inexpensive compared to other fastening methods and can help to reduce installation costs and labor time.

IV. Applications of Impaling Pins for Insulation

A. Building Construction

In building construction, impaling pins are commonly used to secure insulation materials to walls, ceilings, and floors. They are suitable for different types of insulation materials, such as fiberglass, foam, and mineral wool. Impaling pins can help to improve energy efficiency, reduce noise transmission, and enhance the comfort of indoor spaces.

B. Industrial Insulation

In industrial settings, impaling pins are used to insulate pipes, ducts, vessels, and equipment. They are suitable for high-temperature applications and can withstand harsh environments. Impaling pins help to reduce heat loss or gain, prevent condensation, and protect workers from extreme temperatures.

C. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, impaling pins are used to attach insulation materials to ducts and air handlers. This helps to reduce noise transmission, improve energy efficiency, and prevent condensation. Impaling pins are available in different sizes and styles to fit different duct diameters and insulation thicknesses.

D. Automotive Industry

In the automotive industry, impaling pins are used to insulate vehicle interiors and engine compartments. They help to reduce noise and vibration, improve thermal comfort, and protect sensitive electronics. Impaling pins are designed to withstand the vibrations and temperature changes experienced in automotive applications.

E. Aerospace Industry

The aerospace industry also uses impaling pins for insulation applications. They are used to insulate aircraft cabins, engines, and other components. Impaling pins must meet strict quality and safety standards to ensure the reliability and performance of aerospace systems.

V. Installation Methods of Impaling Pins for Insulation

A. Surface Preparation

Before installing impaling pins, it is important to prepare the surface properly. The substrate should be clean, dry, and free from any debris or contaminants. If necessary, the surface can be primed or treated to improve adhesion.

B. Pin Selection

Select the appropriate impaling pins based on the type of insulation, substrate, and installation requirements. Consider factors such as pin length, diameter, material, and load capacity. Make sure to choose pins that are compatible with the insulation material and can provide a secure attachment.

C. Installation Tools

The installation of impaling pins typically requires the use of a hammer or a power tool, such as a pneumatic nail gun or a screw gun. Make sure to use the correct tool for the job and follow the manufacturer's instructions for safe and effective installation.

D. Installation Procedure

To install impaling pins, follow these steps:

1. Mark the location of the pins on the insulation material and the substrate.

2. Insert the pins through the insulation and into the substrate using a hammer or power tool.

3. Ensure that the pins are inserted at the correct depth and angle to provide a secure attachment.

4. Repeat the process as needed to secure the insulation in place.

VI. Maintenance and Care of Impaling Pins for Insulation

A. Regular Inspection

Periodically inspect the impaling pins and insulation system to ensure that they are still in good condition and providing a secure attachment. Look for any signs of damage, such as bent or broken pins, loose insulation, or water damage. Address any issues promptly to prevent further damage and maintain the effectiveness of the insulation system.

B. Cleaning

If the insulation pins become dirty or contaminated, they can be cleaned using a mild detergent and water. Avoid using harsh chemicals or abrasives that could damage the pins or the insulation material. Use a soft cloth or brush to gently clean the pins and remove any debris.

C. Replacement

If the impaling pins become damaged or lose their effectiveness over time, they should be replaced. This may be necessary if the pins are bent, corroded, or pulled out of the substrate. Replace the damaged pins with new ones of the same size and type to ensure a secure attachment and proper insulation performance.

VII. Future Trends and Developments in Impaling Pins for Insulation

A. Technological Advancements

As technology continues to advance, we can expect to see further improvements in the design and performance of impaling pins for insulation. For example, new materials and manufacturing processes may be developed to enhance the strength, durability, and insulation properties of these pins. Additionally, smart pins with integrated sensors or monitoring capabilities may be introduced to provide real-time feedback on the insulation system's performance.

B. Sustainability

With growing concerns about environmental sustainability, there is an increasing demand for eco-friendly insulation solutions. Impaling pins may be developed using recycled or sustainable materials, and manufacturing processes may be optimized to reduce waste and energy consumption. Additionally, the design of impaling pins may be optimized to improve the energy efficiency of insulation systems, helping to reduce overall environmental impact.

C. Customization and Specialization

As insulation needs become more diverse and specialized, we can expect to see more customization and specialization in the design of impaling pins. For example, pins may be developed for specific insulation materials, applications, or environmental conditions. This will allow for more targeted and effective insulation solutions, meeting the unique needs of different industries and applications.

Impaling pins for insulation are a reliable and effective fastening solution that plays an important role in ensuring the proper installation and effectiveness of insulation materials. With their secure attachment, easy installation, versatility, and cost-effectiveness, impaling pins are suitable for a wide range of insulation applications in building construction, industrial settings, HVAC systems, and other industries. By understanding the different types, features, applications, installation methods, and maintenance requirements of impaling pins, you can make informed decisions and ensure the long-term performance and durability of your insulation system. As technology continues to advance and sustainability becomes a greater concern, we can expect to see further developments in impaling pins for insulation, providing even more efficient and eco-friendly solutions for insulation applications.