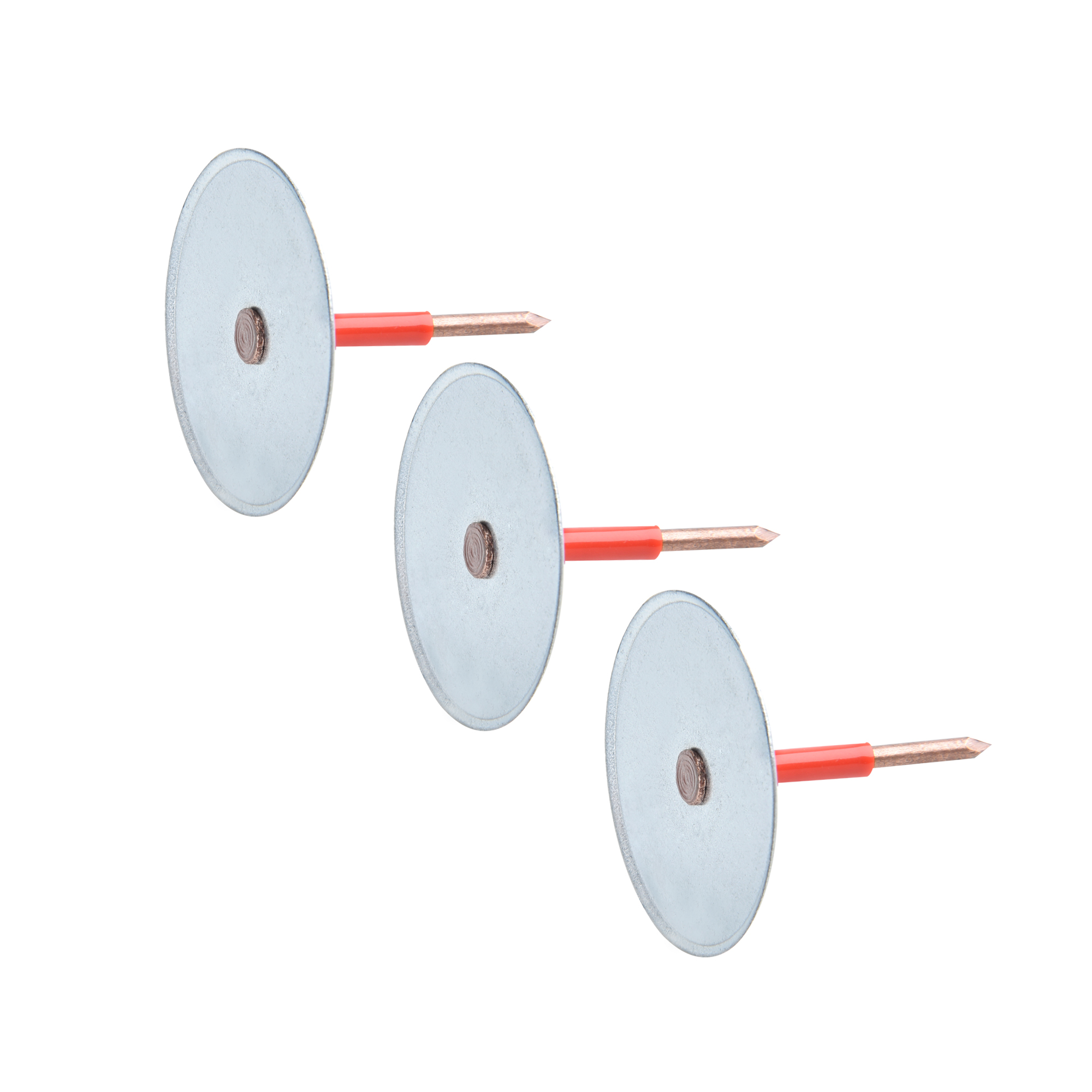

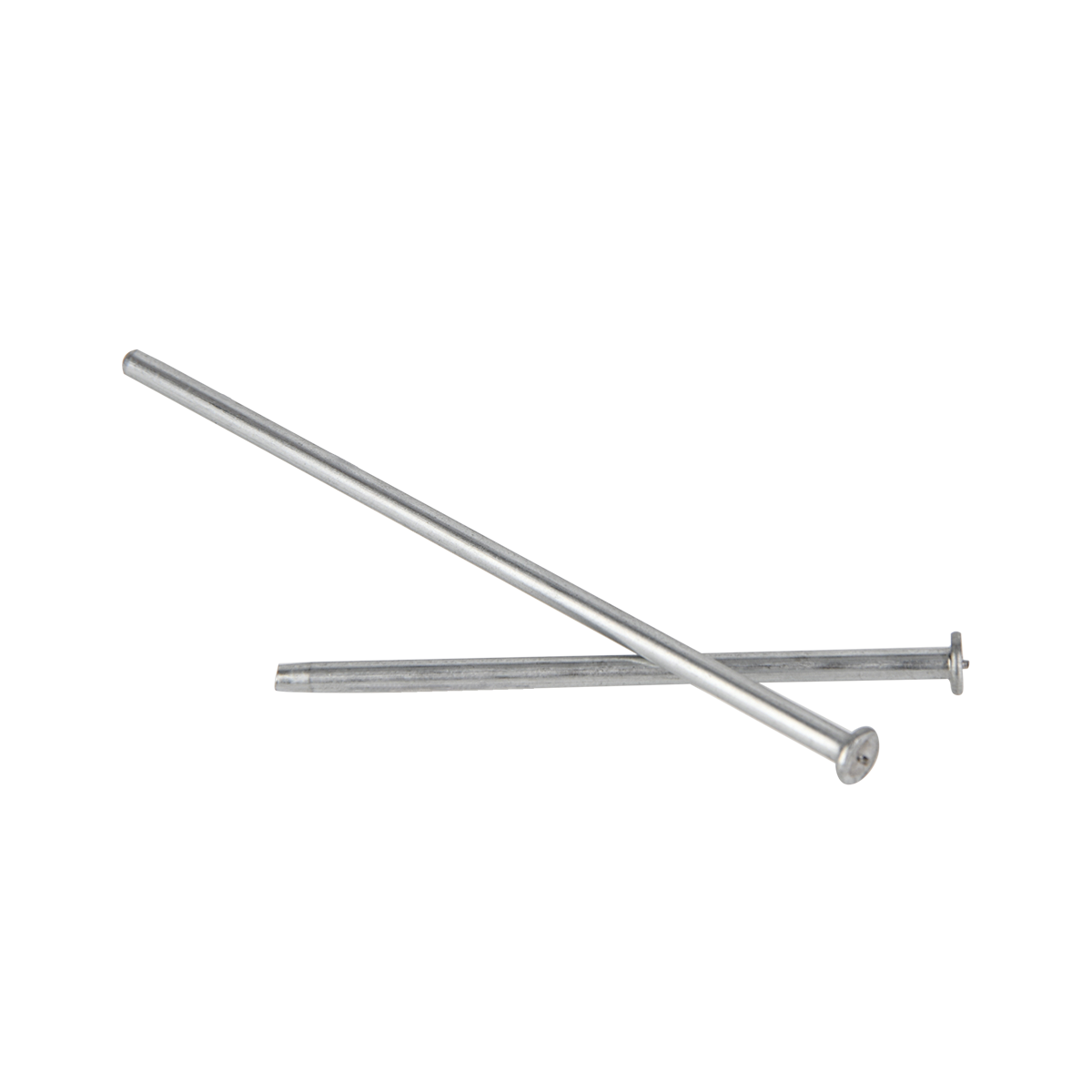

Cup Head Weld Insulation Pins

Cup Head Weld Insulation Pins are an essential component in various insulation applications. Here is an in-depth introduction

Contact

Product Detail

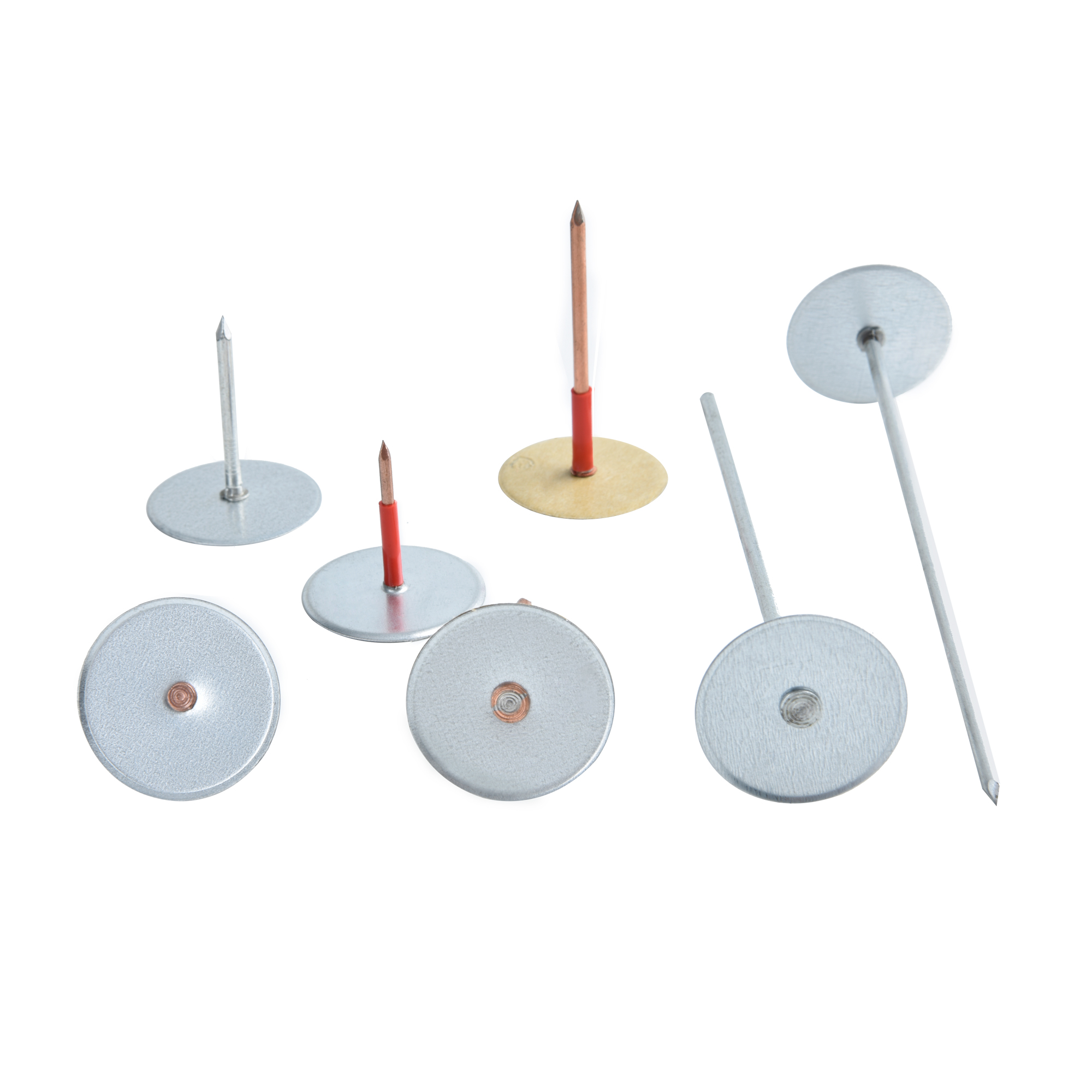

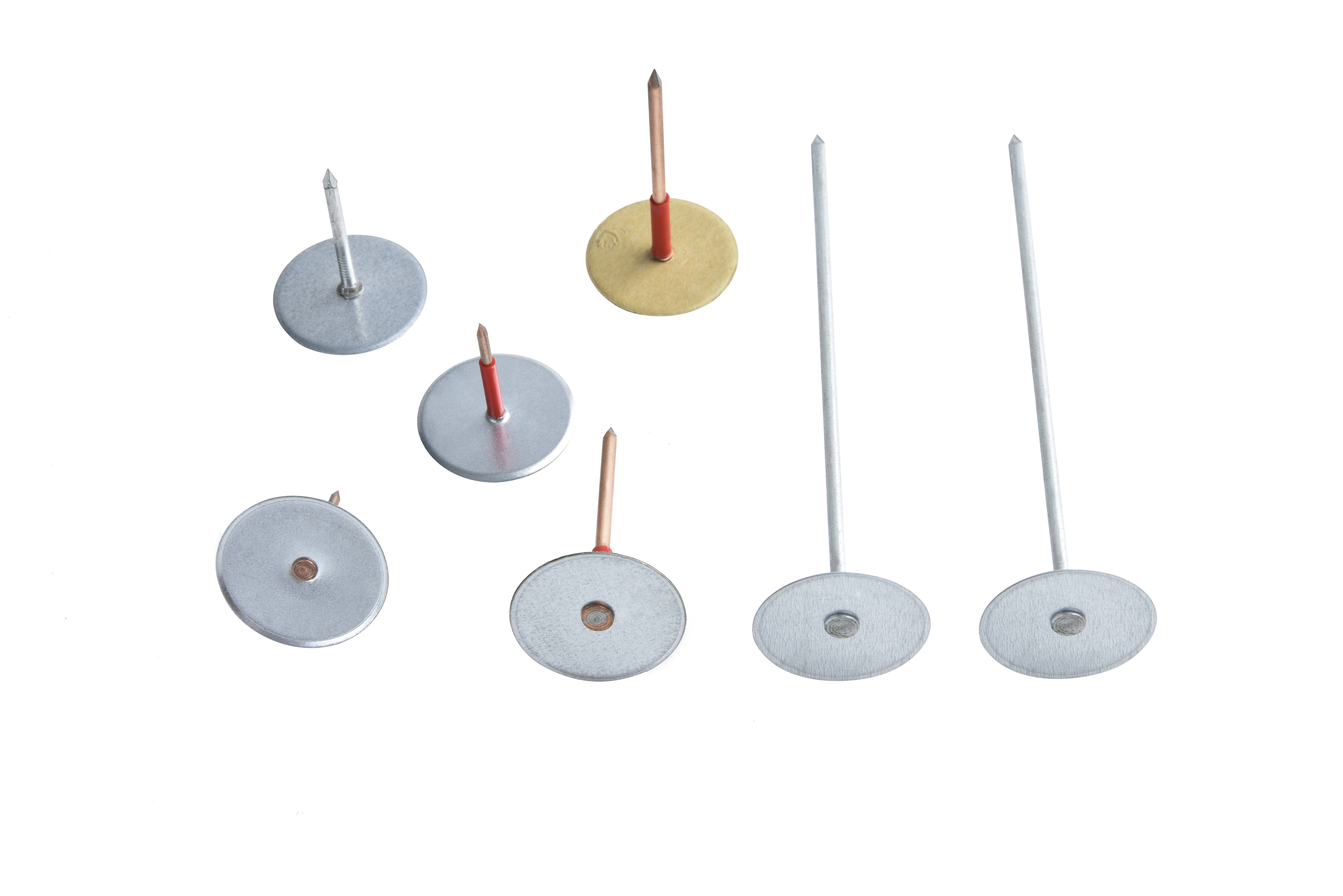

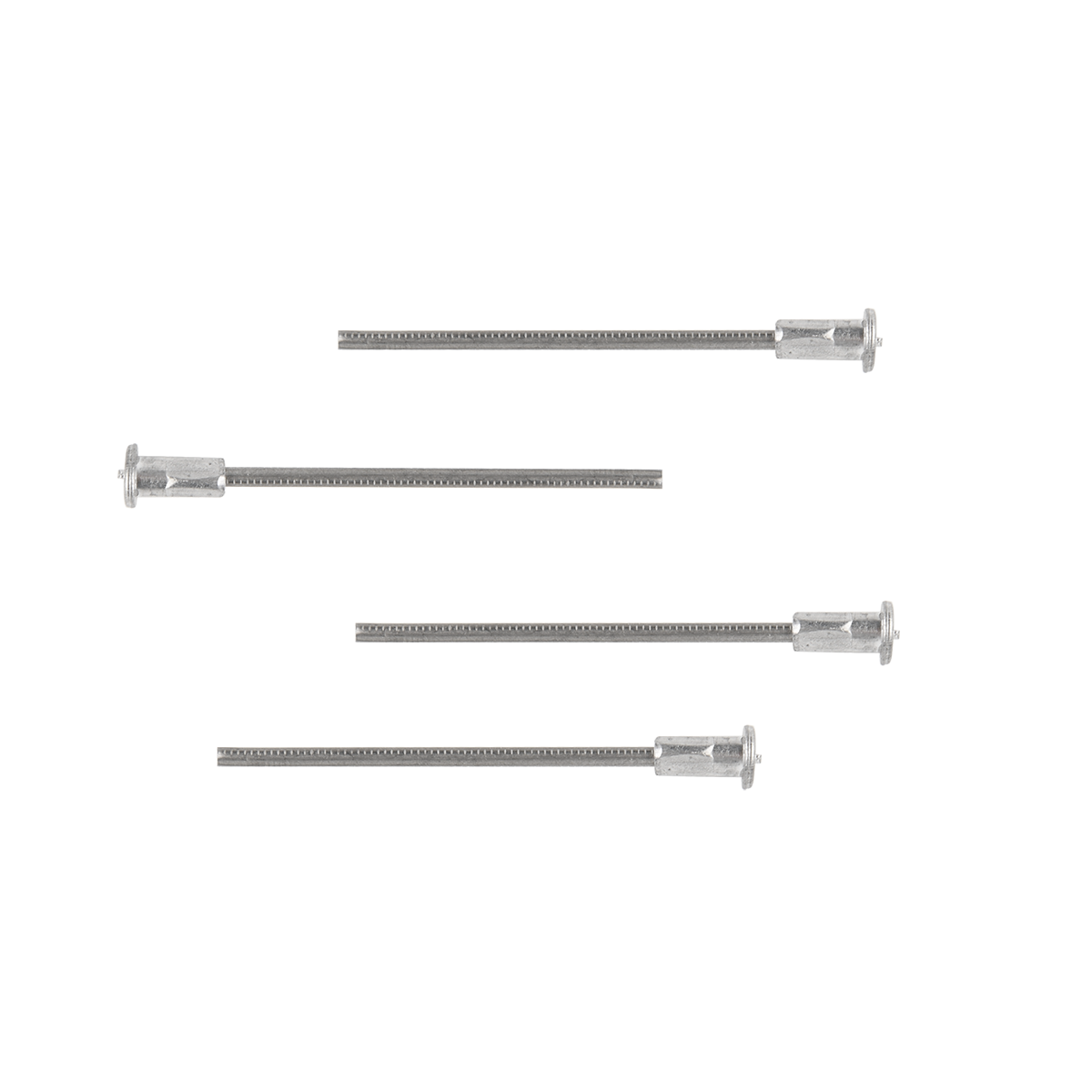

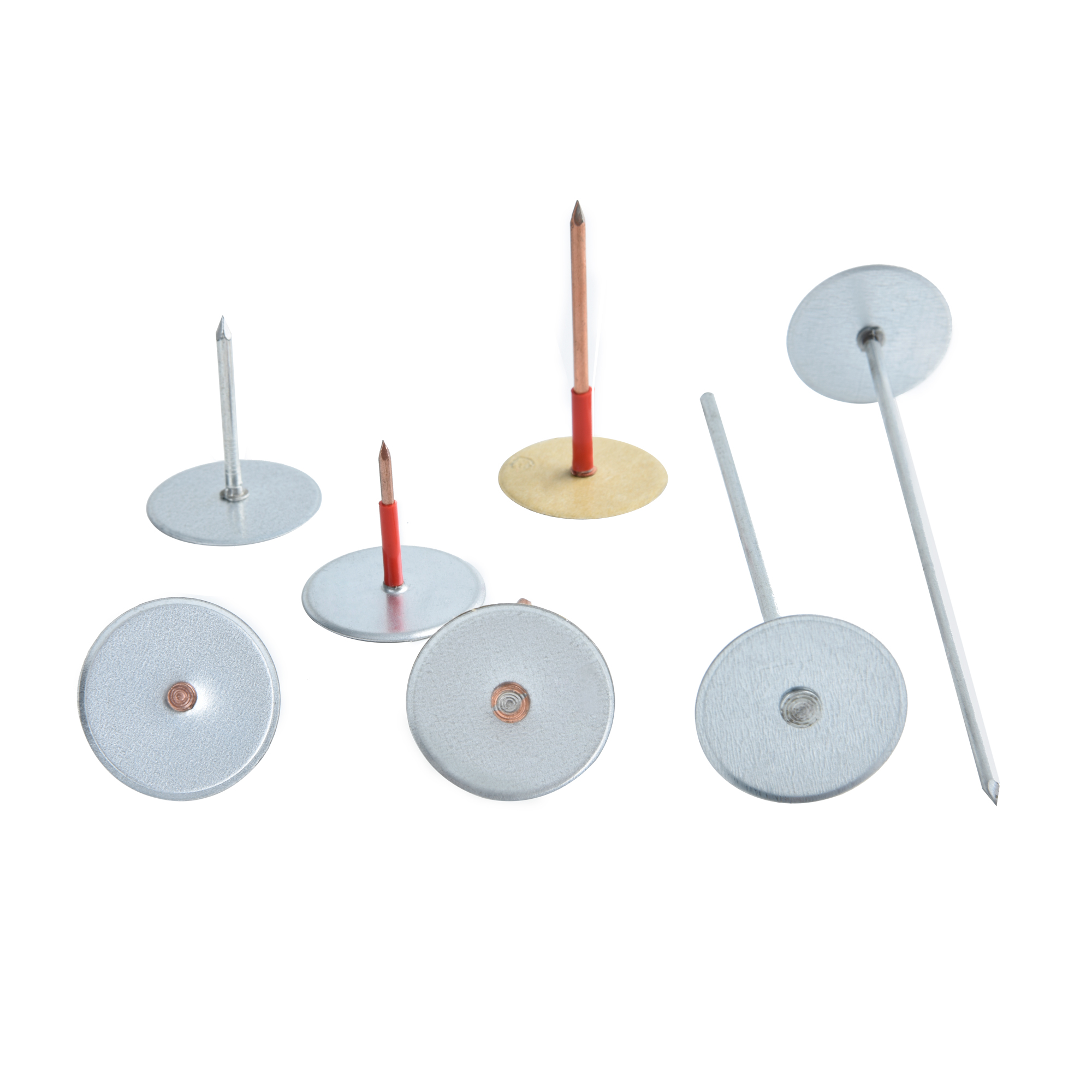

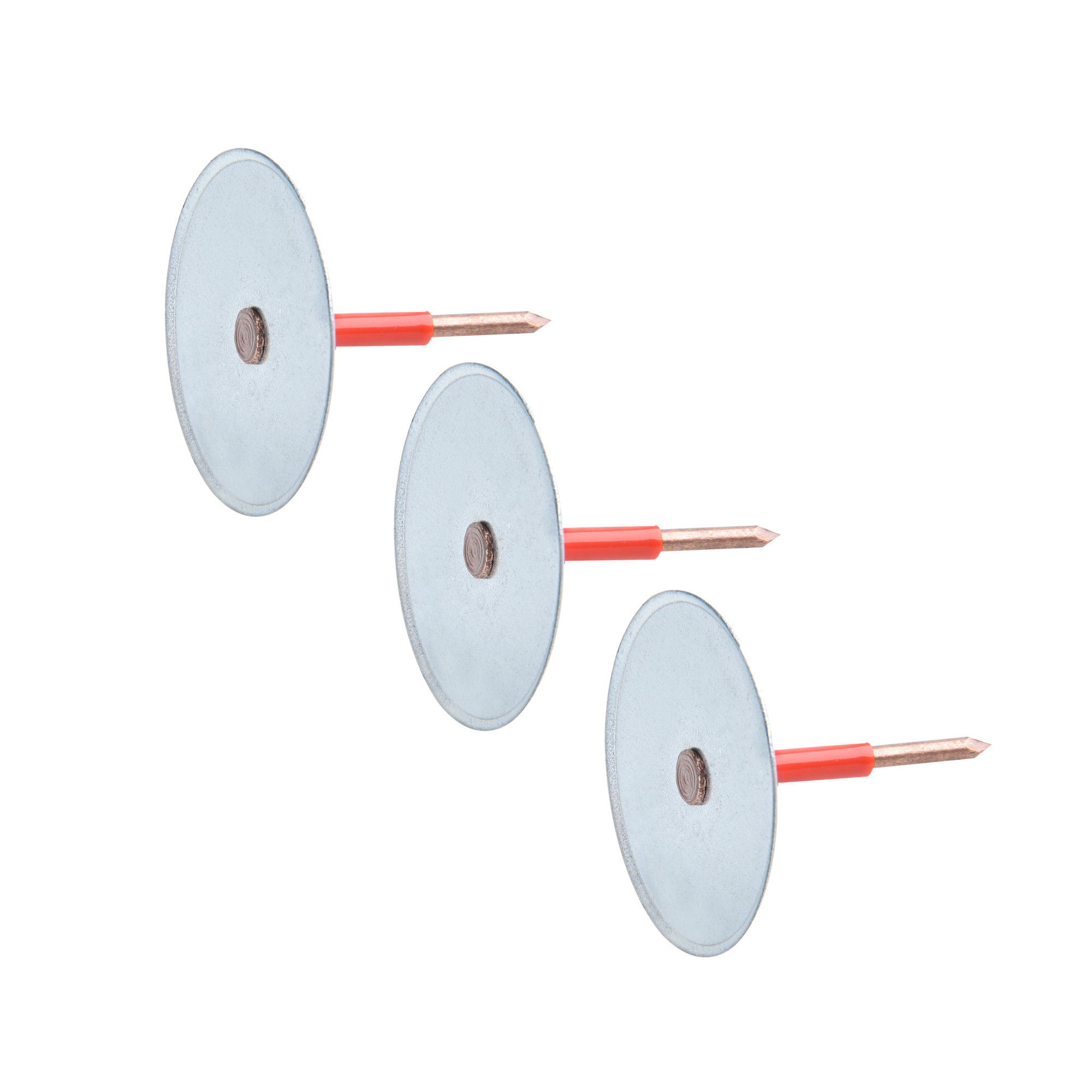

Cup head pins is a kind of weld insulation pins, they are fabricated by a round washer head with a nail, the head diameter is available in 25mm, 30mm and 38mm, the pin diameter is available in 14 Gauge (2.0mm), 12 Gauge( 2.7mm) or 10 Gauge (3.4mm), the material is available in stainless steel, galvanized steel, the pin can be galvanized or copper coated. Our cup head pins are mostly sold to US, Canada and Europe market, In US and Canada, customers purchase them at 30mm (1-3/16") head, the pin diameter is in 12 Gauge, the length will be 3/8" 1" 1-/8" 1-/1/2" 1-7/8" 2" 3" 4" up to 8-1/2" etc. In Europe, customer purchase them at 22mm, 27mm, 32mm, 38mm, 42mm, 48mm, 52mm, 62mm etc, the head is in mild steel galvanized, but the pin will be copper coated or galvanized, customer also need the pin insulated or head insulated or both insulated.

I. Definition and Design

Cup Head Weld Insulation Pins typically consist of a cup-shaped head and a shaft. The cup head provides a larger surface area for contact and stability, while the shaft is designed to penetrate and secure the insulation material. They are often made of materials such as stainless steel or other metals that offer durability and resistance to corrosion.

II. Functions and Purposes

The primary function of these pins is to hold insulation materials firmly in place. In construction and industrial settings, where insulation is used to prevent heat transfer, reduce energy consumption, and maintain temperature control, these pins ensure that the insulation stays put and performs effectively. They prevent the insulation from sagging, shifting, or being dislodged due to various factors like gravity, vibration, or air movement.

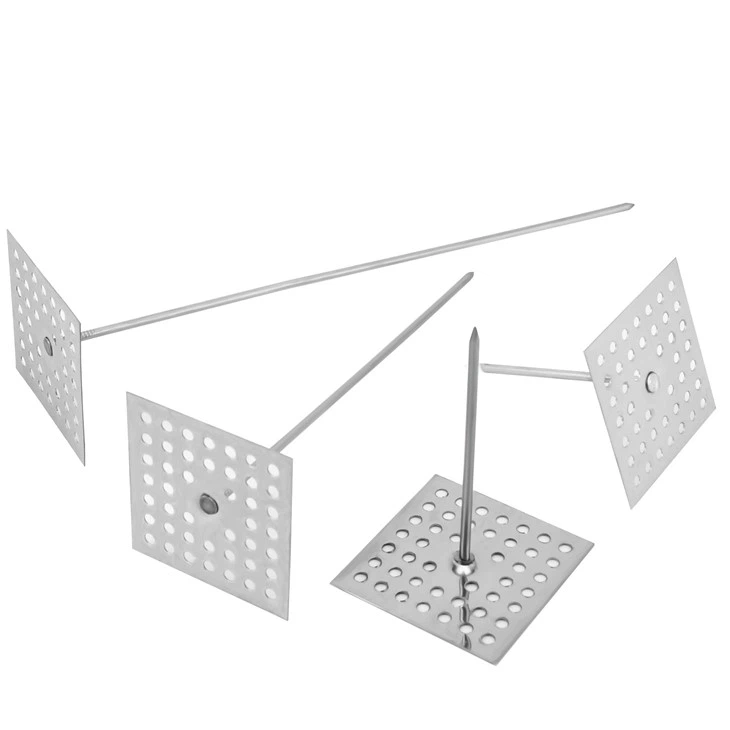

III. Types and Variations

There are different types of Cup Head Weld Insulation Pins available in the market, varying in terms of size, length, and material composition. Some may have special coatings or finishes to enhance their adhesion or resistance to specific environmental conditions. For example, there are pins designed for high-temperature applications, while others are suitable for general-purpose insulation.

IV. Installation Process

The installation of Cup Head Weld Insulation Pins usually involves the following steps. First, the surface where the insulation is to be applied is prepared, ensuring it is clean and free from debris. Then, the pins are positioned at the appropriate intervals, depending on the type and thickness of the insulation. Using a welding tool, the pins are welded to the substrate, firmly attaching them. Once the pins are in place, the insulation material can be installed and secured by pushing it onto the pins.

V. Advantages and Benefits

Enhanced Insulation Performance: By securely holding the insulation, they help maintain the integrity of the insulation layer, leading to improved thermal insulation and energy efficiency.

Long-Term Durability: The quality materials and construction ensure that the pins can withstand the rigors of the environment over a long period, reducing the need for frequent replacements.

Versatility: They can be used in a wide range of applications, including walls, roofs, pipes, and equipment insulation.

Easy Installation: With a relatively straightforward installation process, they save time and labor costs compared to some other fastening methods.

VI. Applications in Different Industries

Construction Industry: In buildings, they are used for insulating walls, roofs, and floors to improve energy efficiency and thermal comfort. They are also employed in fireproofing applications to hold fire-resistant insulation materials in place.

Industrial Sector: In industrial plants and facilities, these pins are used to insulate pipes, ducts, boilers, and other equipment to prevent heat loss or gain, reduce energy consumption, and protect workers from hot or cold surfaces.

HVAC Systems: They play a crucial role in the installation of insulation in heating, ventilation, and air conditioning systems, ensuring proper air circulation and temperature control.

VII. Considerations and Precautions

Compatibility with Insulation Material: It is essential to choose pins that are compatible with the type of insulation being used to ensure proper adhesion and performance.

Proper Installation Technique: Following the correct installation procedures is crucial to achieve a secure and effective fastening. This includes using the appropriate welding equipment and techniques and ensuring the pins are positioned correctly.

Environmental Factors: Consideration should be given to the environmental conditions in which the pins will be used, such as temperature, humidity, and exposure to chemicals, to select the most suitable material and coating.

In conclusion, Cup Head Weld Insulation Pins are a vital component in insulation systems, providing a reliable and efficient way to hold insulation materials in place. Their proper selection, installation, and use can significantly contribute to the effectiveness of insulation, energy savings, and the overall performance of buildings and industrial facilities. However, it is important to take into account the specific requirements of each application and follow the recommended guidelines to ensure optimal results.