Insulation Pins and Insulation Clips

Insulation PinsInsulation pins are essential components used in various applications where insulatio

Contact

Product Detail

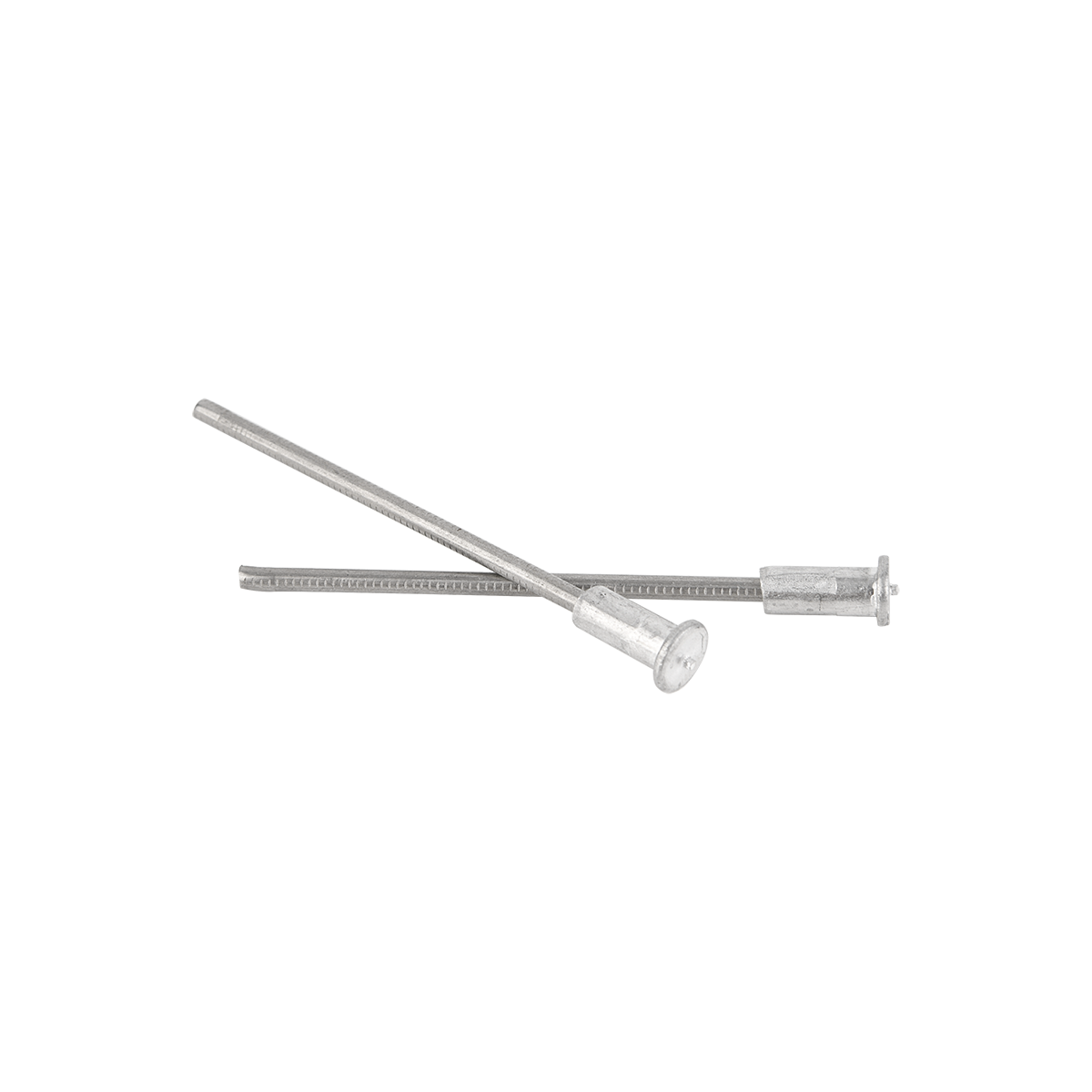

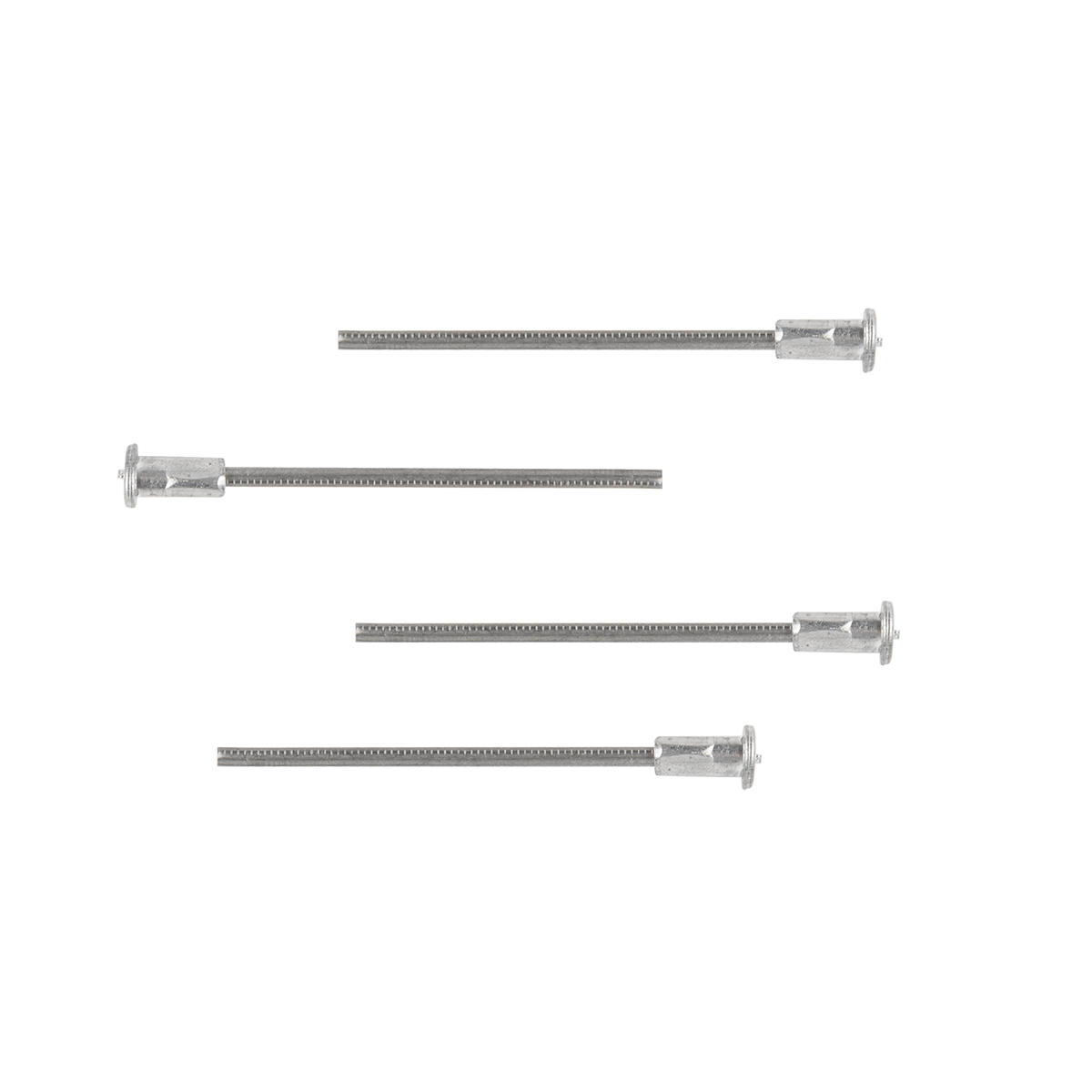

Insulation Pins

Insulation pins are commonly made from materials such as stainless steel, nylon, or other durable and heat-resistant substances. Their main purpose is to hold insulation in place, preventing it from shifting or coming loose. This is particularly important in industries like construction, HVAC (Heating, Ventilation, and Air Conditioning), and automotive.

In the construction sector, insulation pins are used to fix insulation materials to walls, roofs, and floors. They help to create an effective thermal barrier, reducing heat loss or gain and improving energy efficiency. For example, in a residential building, insulation pins ensure that the insulation layer stays in position within the walls, enhancing the comfort of the occupants and lowering energy consumption for heating and cooling.

In the HVAC industry, insulation pins are employed to attach insulation to ductwork. This helps to maintain the desired temperature within the ducts and minimize heat transfer to or from the surrounding environment. It ensures that the conditioned air reaches its destination with minimal loss of efficiency.

Automotive applications also make use of insulation pins. They can be found in engine compartments, where they hold insulation materials to reduce noise and heat. This not only improves the driving experience but also protects other components from excessive heat.

The design of insulation pins can vary depending on the specific requirements of the application. Some pins have sharp tips for easy penetration into the substrate, while others have barbs or flanges to provide better grip. The size and shape of the pins are selected based on the thickness and type of insulation material being used.

When choosing insulation pins, factors such as the material's resistance to corrosion, temperature tolerance, and load-bearing capacity need to be considered. Different environments and applications may demand specific properties to ensure the longevity and performance of the pins.

In conclusion, insulation pins play a vital role in ensuring the proper installation and effectiveness of insulation in a wide range of industries. Their importance lies in maintaining energy efficiency, reducing noise, and protecting components from heat and other environmental factors.

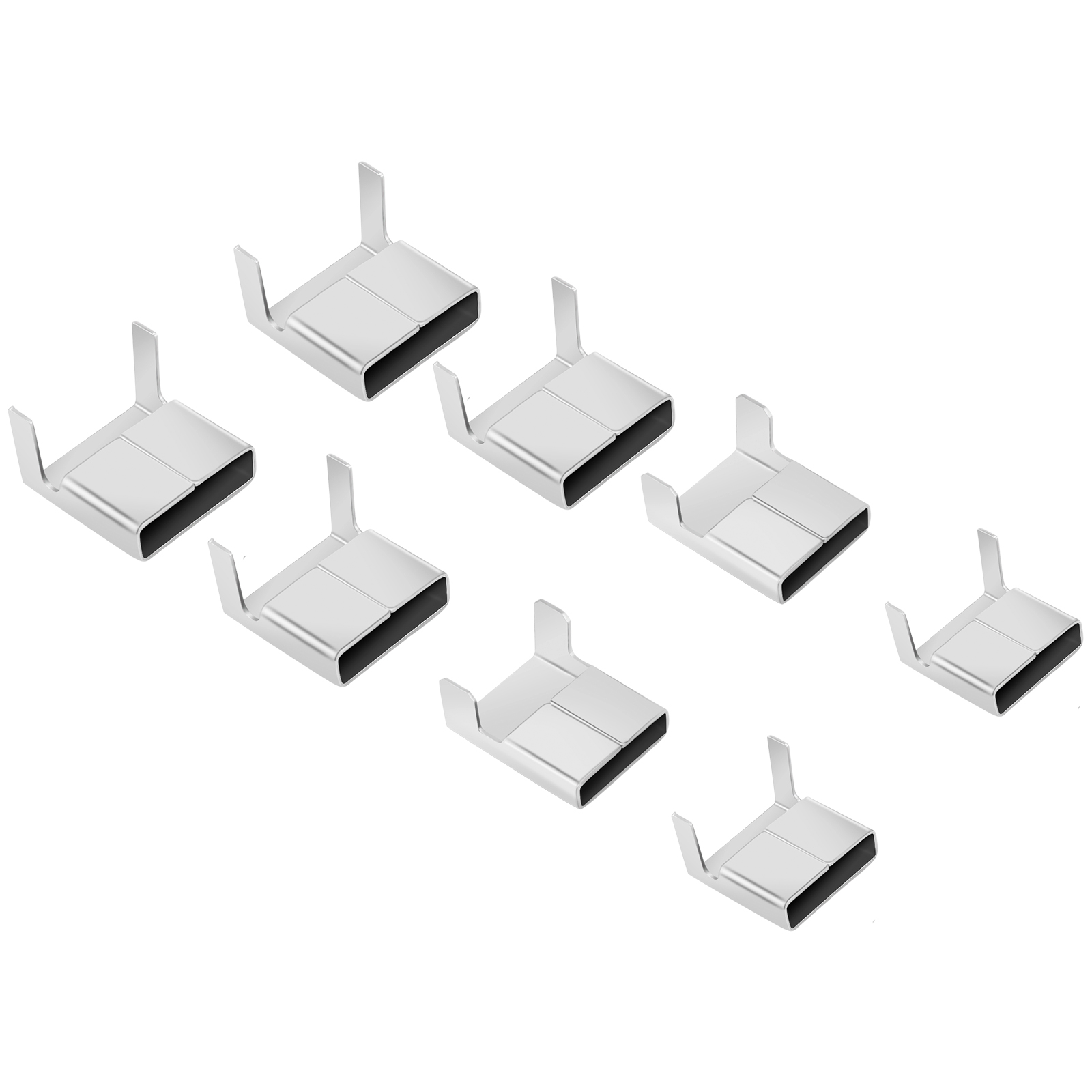

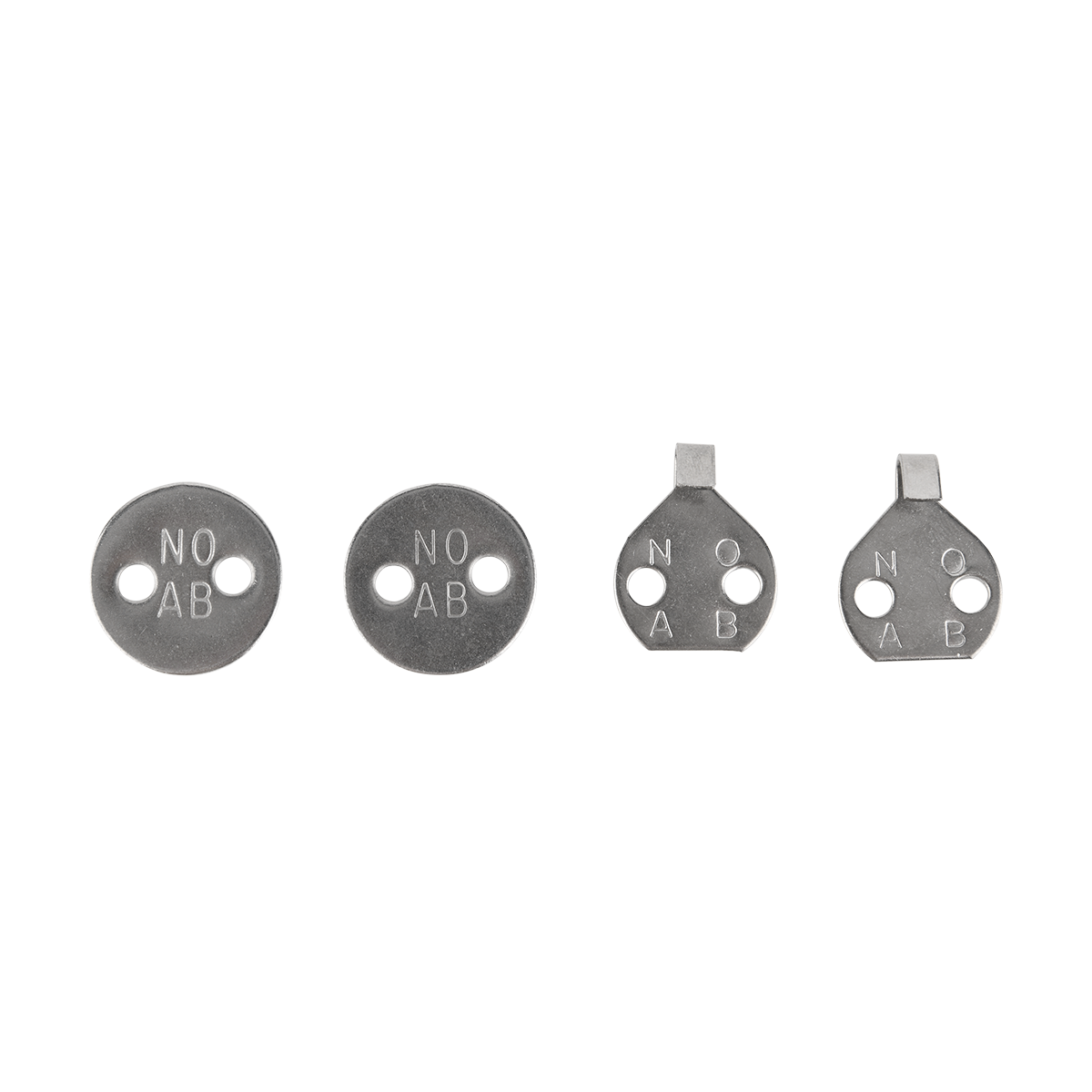

Insulation Clips

Insulation clips are another important tool in the world of insulation installation and maintenance. These clips are designed to hold insulation materials firmly in place, offering stability and support.

Insulation clips come in a variety of shapes and sizes, each tailored to specific insulation types and installation scenarios. They can be made from materials like metal, plastic, or a combination of both, depending on the application and environmental conditions.

In the industrial setting, insulation clips are often used in large-scale insulation projects. For instance, in power plants or manufacturing facilities, where high-temperature insulation is required, clips made from heat-resistant alloys are employed to secure the insulation around pipes and equipment. These clips ensure that the insulation remains intact even in extreme conditions, preventing heat loss and protecting workers from potential burns.

In commercial buildings, insulation clips are used to attach insulation to ceilings and walls. They provide a secure hold, allowing the insulation to perform its thermal and acoustic insulation functions effectively. This is especially important in spaces like offices, hospitals, and shopping malls where maintaining a comfortable environment is crucial.

One common type of insulation clip is the spring-loaded clip. This design exerts a constant pressure on the insulation, keeping it snug against the surface. Another type is the snap-on clip, which is easy to install and provides a quick and reliable fastening solution.

When installing insulation clips, it's essential to follow the manufacturer's instructions and ensure they are spaced appropriately to distribute the load evenly. This helps to prevent sagging or detachment of the insulation over time.

Insulation clips also contribute to the overall durability of the insulation system. By preventing movement and damage to the insulation, they extend its lifespan and reduce the need for frequent maintenance and replacements.

In summary, insulation clips are indispensable components that enhance the performance and longevity of insulation systems in various applications, from industrial to commercial and residential. Their proper selection and installation are key to achieving efficient insulation and a comfortable living or working environment.

Self Adhesive Insulation Pins

Introduction:

Self adhesive insulation pins are an innovative and highly useful product in the field of insulation and construction. These pins play a crucial role in ensuring proper insulation installation and maintaining the integrity of insulated materials. In this extensive introduction, we will explore the various aspects of self adhesive insulation pins, including their design, features, applications, benefits, and installation process.

Design and Features:

Self adhesive insulation pins are typically made of high-quality materials such as plastic or metal. The pins are designed with a sharp point at one end to easily penetrate insulation materials and a flat head at the other end to provide a stable base. The most distinctive feature of these pins is the self-adhesive backing. This adhesive is usually a strong and durable bonding agent that allows the pins to stick firmly to various surfaces.

The design of self adhesive insulation pins takes into account the need for ease of use and effectiveness. The pins are often manufactured in different lengths and diameters to accommodate different insulation thicknesses and installation requirements. Some pins may also have additional features such as anti-corrosion coatings or special finishes to enhance their durability and performance.

The self-adhesive backing is carefully engineered to provide a strong bond that can withstand the rigors of insulation installation and long-term use. The adhesive is typically resistant to moisture, temperature variations, and chemicals, ensuring that the pins remain securely attached even in harsh environments.

Applications:

Self adhesive insulation pins have a wide range of applications in various industries and settings. One of the main areas where these pins are commonly used is in building and construction. They are ideal for insulating walls, ceilings, and floors, as they help to hold insulation materials in place and prevent sagging or shifting.

In industrial settings, self adhesive insulation pins are used for insulating pipes, ducts, and equipment. They can be used to secure insulation blankets, foam insulation, or other types of insulation materials to metal or plastic surfaces. This helps to reduce heat loss or gain, improve energy efficiency, and protect workers from extreme temperatures.

The automotive industry also makes use of self adhesive insulation pins. They are used to insulate engine compartments, exhaust systems, and other areas of vehicles to reduce noise and heat transfer. Additionally, these pins can be used in the aerospace industry for insulating aircraft components and ensuring proper thermal management.

Benefits:

There are several benefits to using self adhesive insulation pins. One of the main advantages is their ease of installation. Unlike traditional insulation pins that require drilling or nailing, self adhesive pins can be simply pressed onto the surface, saving time and effort. This makes them ideal for both professional installers and DIY enthusiasts.

Another benefit is the strong bond provided by the self-adhesive backing. This ensures that the insulation materials remain securely in place, reducing the risk of gaps or air leaks. This can lead to improved insulation performance and energy savings.

Self adhesive insulation pins are also highly durable. The materials used in their construction are designed to withstand the elements and resist wear and tear. This means that they can provide long-lasting insulation support and require minimal maintenance.

In addition, these pins are often cost-effective compared to other insulation installation methods. They eliminate the need for specialized tools or equipment, reducing installation costs. Moreover, their reliable performance can lead to lower energy bills over time, further enhancing their cost-effectiveness.

Installation Process:

Installing self adhesive insulation pins is a relatively simple process. Here are the general steps involved:

1. Prepare the surface: Ensure that the surface where the pins will be installed is clean, dry, and free from dust, dirt, or grease. This will help ensure a strong bond.

2. Measure and mark: Determine the placement of the pins based on the insulation requirements. Use a measuring tape and marker to mark the locations where the pins will be installed.

3. Peel off the backing: Carefully peel off the adhesive backing from the pins. Be careful not to touch the adhesive surface to avoid reducing its stickiness.

4. Apply the pins: Press the pins firmly onto the marked locations. Apply even pressure to ensure a good bond. Make sure that the pins are inserted straight and perpendicular to the surface.

5. Install insulation: Once the pins are in place, install the insulation materials. Follow the manufacturer's instructions for proper installation techniques.

6. Check and adjust: After installing the insulation, check to make sure that the pins are holding the insulation firmly in place. If necessary, adjust the position of the pins or add additional pins for better support.

Conclusion:

Self adhesive insulation pins are a valuable tool for insulation installation in a variety of applications. Their unique design, featuring a self-adhesive backing, makes them easy to install, highly durable, and cost-effective. Whether in building construction, industrial settings, or the automotive and aerospace industries, these pins can help improve insulation performance, reduce energy consumption, and enhance overall comfort and safety. By understanding their features, applications, benefits, and installation process, you can make an informed decision about using self adhesive insulation pins for your insulation needs.