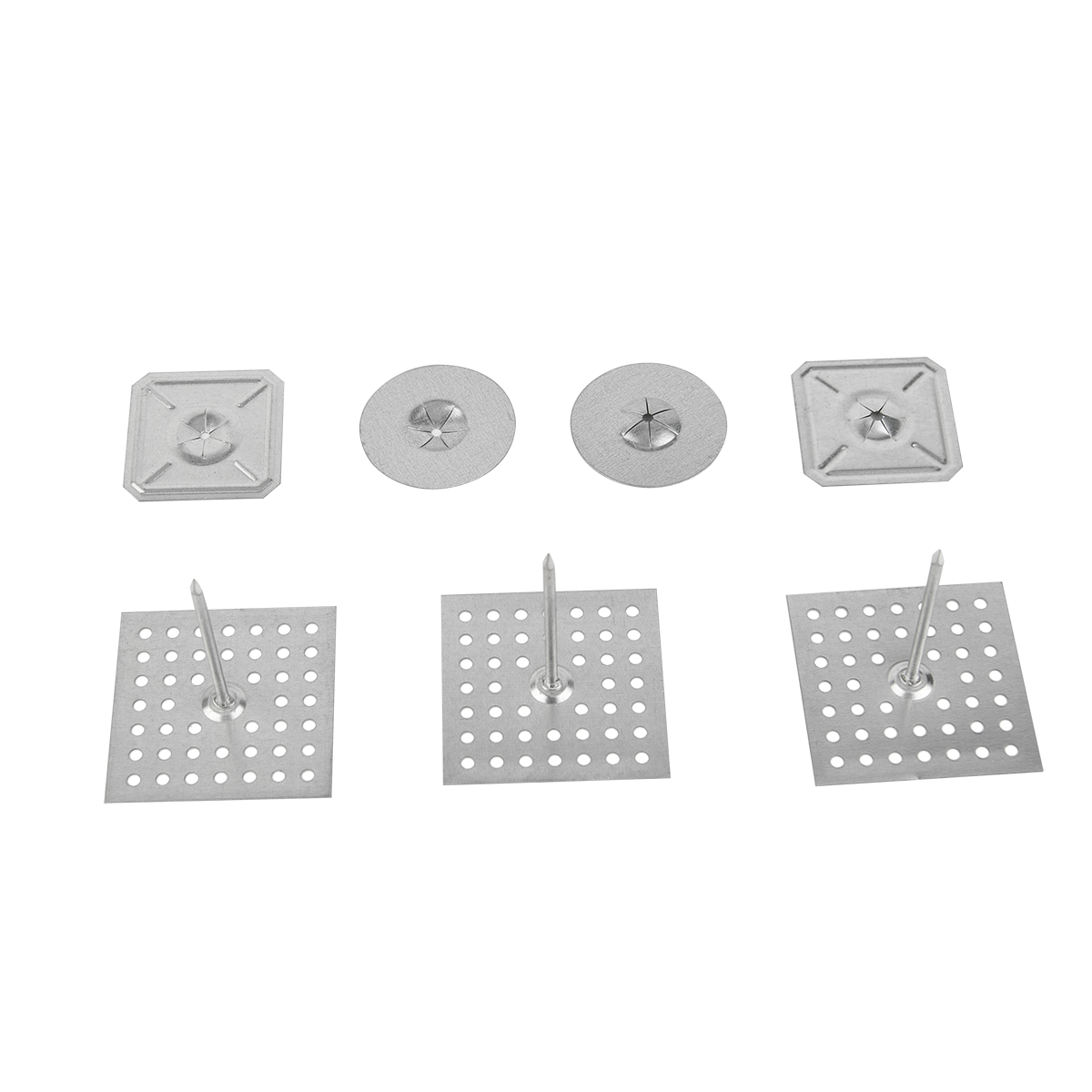

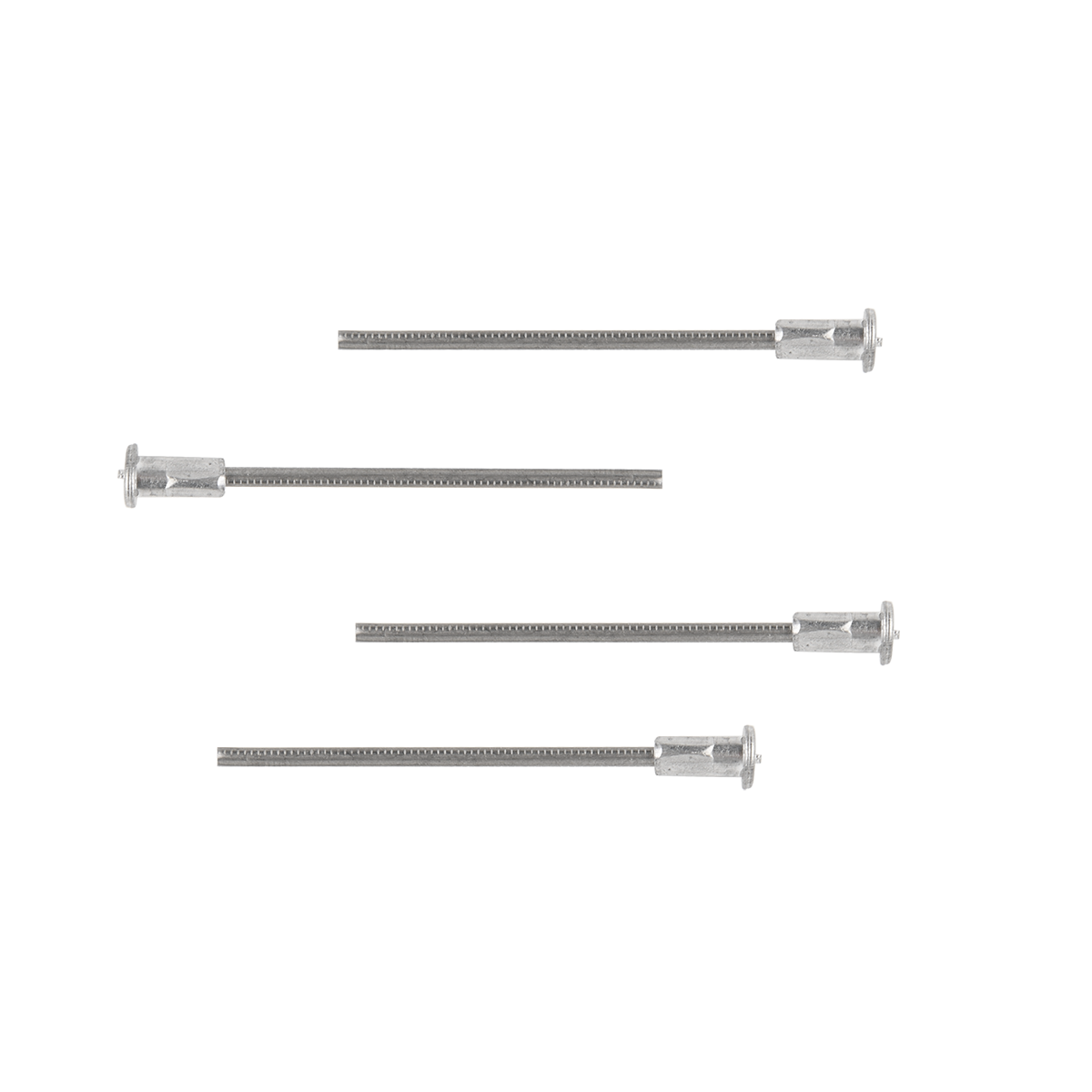

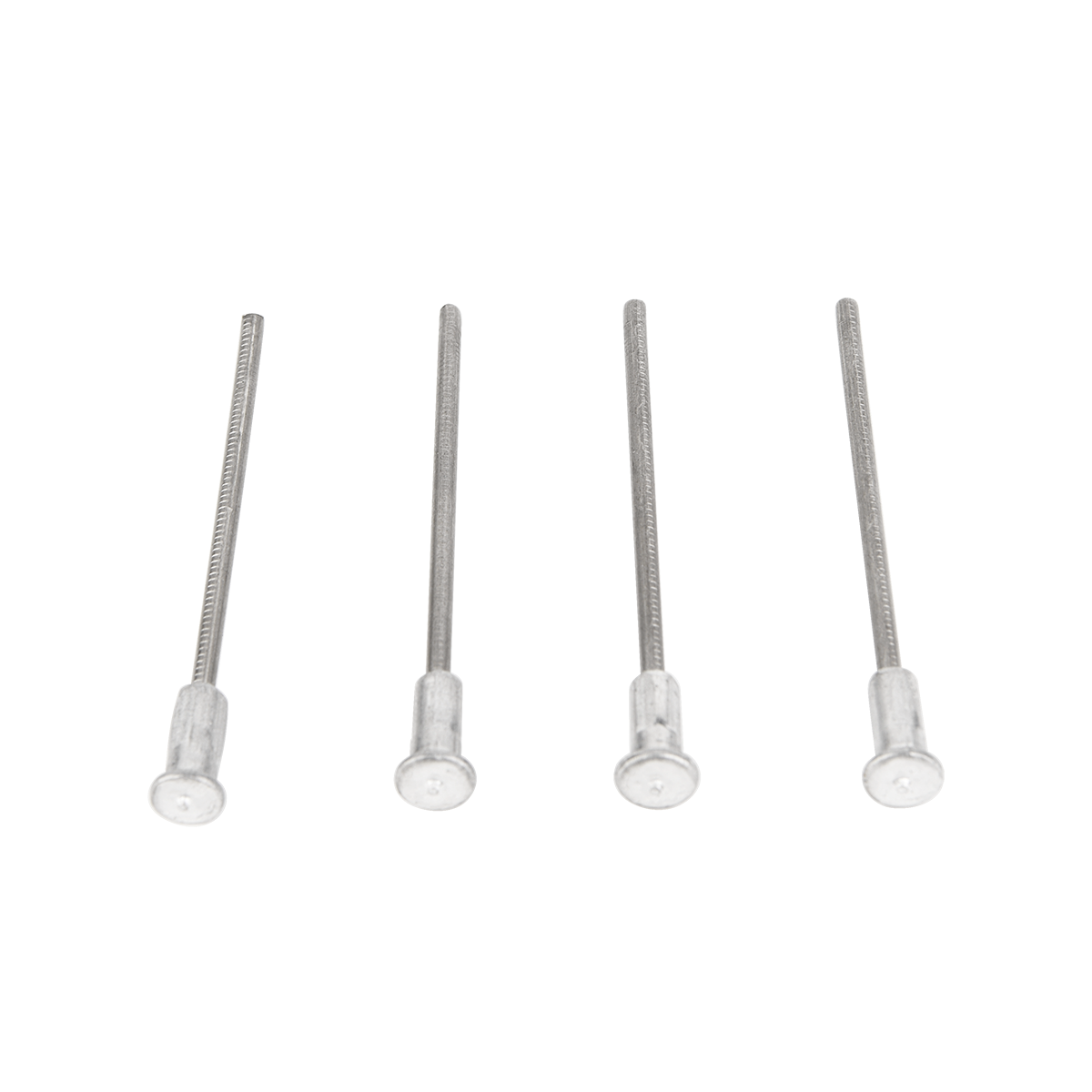

Galvanised Steel Insulation Pins

Galvanised steel insulation pins are an essential component in various insulation applications, offering a combination of strength, durability, and corrosion resistance. In this detailed article, we will explore the numerous aspects of galvanised steel insulation pins.

Contact

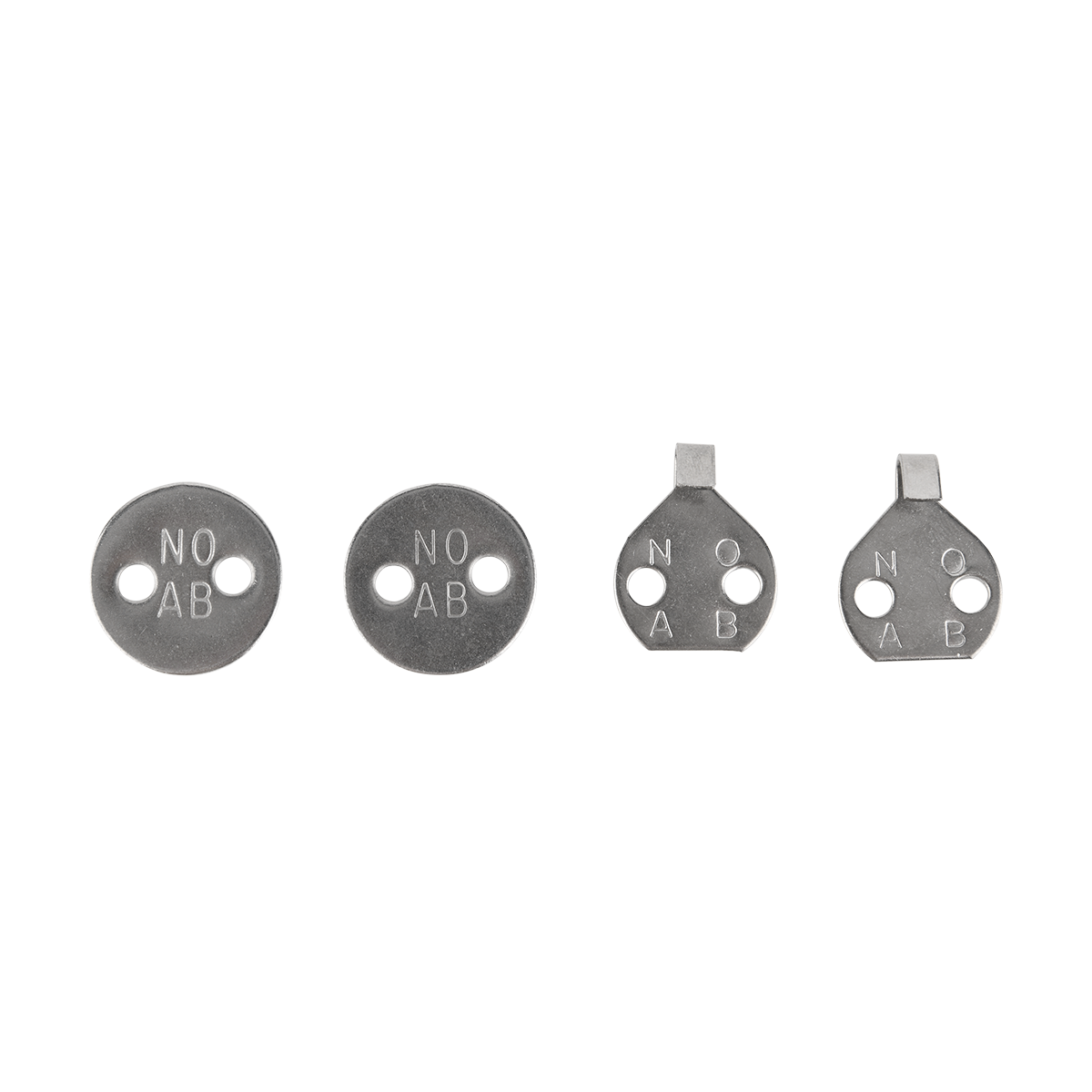

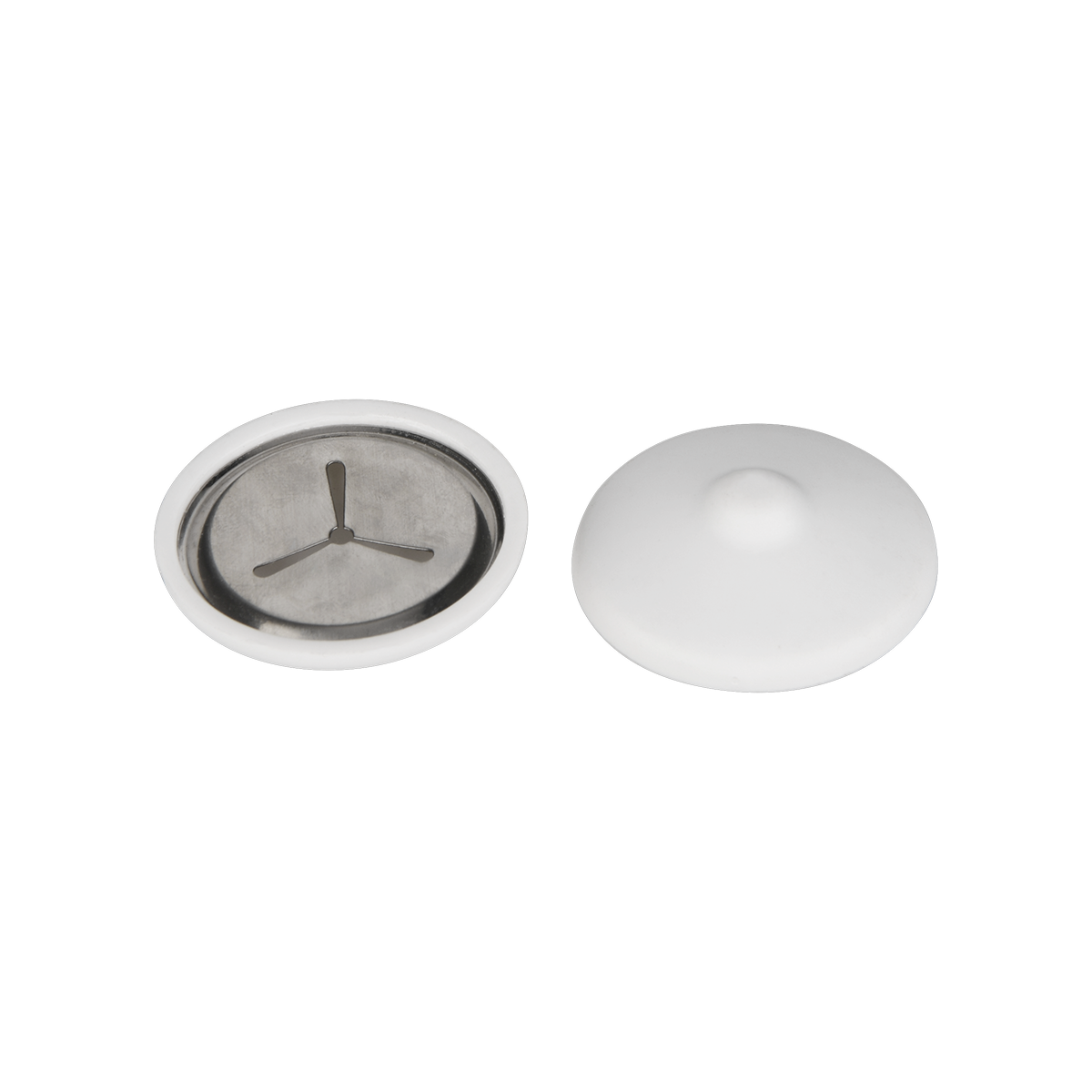

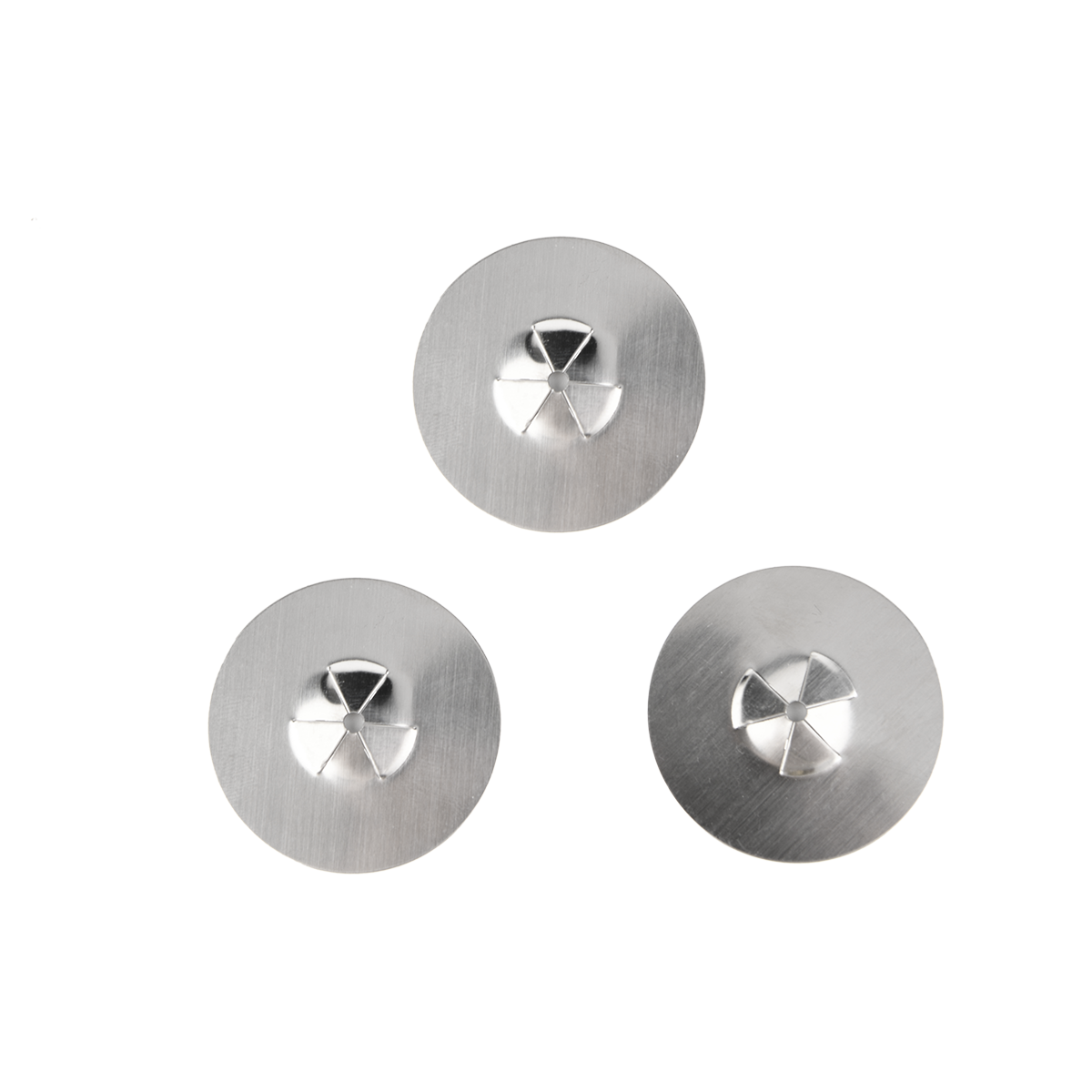

Product Detail

Properties and Characteristics of Galvanised Steel Insulation Pins

Galvanised steel insulation pins possess several unique properties that make them highly suitable for insulation purposes. The galvanisation process provides a protective coating to the steel, enhancing its corrosion resistance. This is crucial as insulation pins are often exposed to moisture, chemicals, and varying environmental conditions.

The steel core of these pins ensures high strength and load-bearing capacity. They can withstand the mechanical stresses and forces exerted on the insulation materials without deformation or failure. Additionally, the pins have good thermal conductivity, which, when managed properly in insulation systems, does not compromise the overall insulation performance.

Advantages of Galvanised Steel Insulation Pins

One of the significant advantages of galvanised steel insulation pins is their longevity. The galvanised coating protects the steel from rust and corrosion, allowing the pins to maintain their integrity and functionality over an extended period. This reduces the need for frequent replacements and lowers maintenance costs.

Another advantage is their compatibility with a wide range of insulation materials. Whether it's fiberglass, foam, or other types of insulation, galvanised steel pins can effectively secure and hold the insulation in place.

They also offer excellent stability and reliability. In applications where insulation is critical for safety and performance, such as in industrial settings or construction projects, the consistent quality and performance of galvanised steel insulation pins provide peace of mind.

Applications of Galvanised Steel Insulation Pins

Galvanised steel insulation pins find extensive use in several industries and applications.

In the construction industry, they are employed to fix insulation materials to walls, roofs, and floors. This helps improve the energy efficiency of buildings by reducing heat transfer. For example, in commercial buildings, these pins are used to attach insulation panels to the exterior walls, contributing to lower heating and cooling costs.

In industrial facilities, such as factories and power plants, they are used to insulate pipes, ducts, and equipment. The pins help maintain the desired temperature within the systems and prevent heat loss or gain.

The automotive industry also utilises galvanised steel insulation pins for sound and heat insulation in vehicles.

Manufacturing Process of Galvanised Steel Insulation Pins

The manufacturing process of galvanised steel insulation pins involves several steps.

The steel is first selected based on its quality and properties to meet the required strength and durability standards. The steel is then shaped and formed into the desired pin configuration through processes like stamping, forging, or machining.

After the pins are formed, they undergo the galvanisation process. This typically involves immersing the pins in a bath of molten zinc or applying a zinc coating through electro-galvanisation. The zinc adheres to the steel surface, creating a protective layer.

Quality control checks are conducted at various stages of the manufacturing process to ensure the pins meet the specified dimensions, strength, and coating thickness requirements.

Installation and Handling of Galvanised Steel Insulation Pins

Proper installation is essential to maximise the performance and effectiveness of galvanised steel insulation pins.

Before installation, the surface where the pins will be fixed should be prepared by cleaning and ensuring it is free from dirt, grease, or any substances that could affect the adhesion.

The pins should be inserted at the correct angle and depth to provide a secure hold. Special tools or equipment may be used depending on the application and the type of insulation material.

When handling the pins, care should be taken to avoid damaging the galvanised coating. Gloves should be worn to prevent fingerprints or oils from coming into contact with the coating, which could potentially compromise its corrosion resistance.

Quality Control and Standards for Galvanised Steel Insulation Pins

To ensure the quality and performance of galvanised steel insulation pins, strict quality control measures and adherence to industry standards are crucial.

Quality control tests may include checks for the thickness and uniformity of the galvanised coating, the mechanical strength of the pins, and their dimensional accuracy. Common standards that these pins may comply with include international and national standards related to insulation materials and fasteners.

Manufacturers often conduct regular audits and inspections of their production processes to maintain consistent quality.

Future Trends and Developments in Galvanised Steel Insulation Pins

As technology advances and the demand for more efficient and sustainable insulation solutions grows, there are likely to be several developments in the field of galvanised steel insulation pins.

Research may focus on improving the galvanisation process to provide even better corrosion protection and longer service life. New designs and shapes of pins may be developed to accommodate emerging insulation materials and installation techniques.

There may also be an increased emphasis on environmentally friendly manufacturing processes and the use of recyclable materials.

In conclusion, galvanised steel insulation pins play a vital role in insulation systems across various industries. Their properties, advantages, and wide range of applications make them an indispensable component. Understanding their manufacturing, installation, and quality control aspects is essential for ensuring their optimal performance and contribution to efficient insulation solutions.

It should be noted that the above content is a detailed overview and can be further expanded and customised based on specific requirements and additional research.