Cup Head Weld Insulation Pins Design

The design of Cup Head Weld Insulation Pins aims to meet the special needs of various industrial env

Contact

Product Detail

The design of Cup Head Weld Insulation Pins aims to meet the special needs of various industrial environments, especially insulation material fixation under high temperature and high voltage conditions. The design focuses on structural shape, material selection, and welding techniques to ensure the performance and durability of the nails.

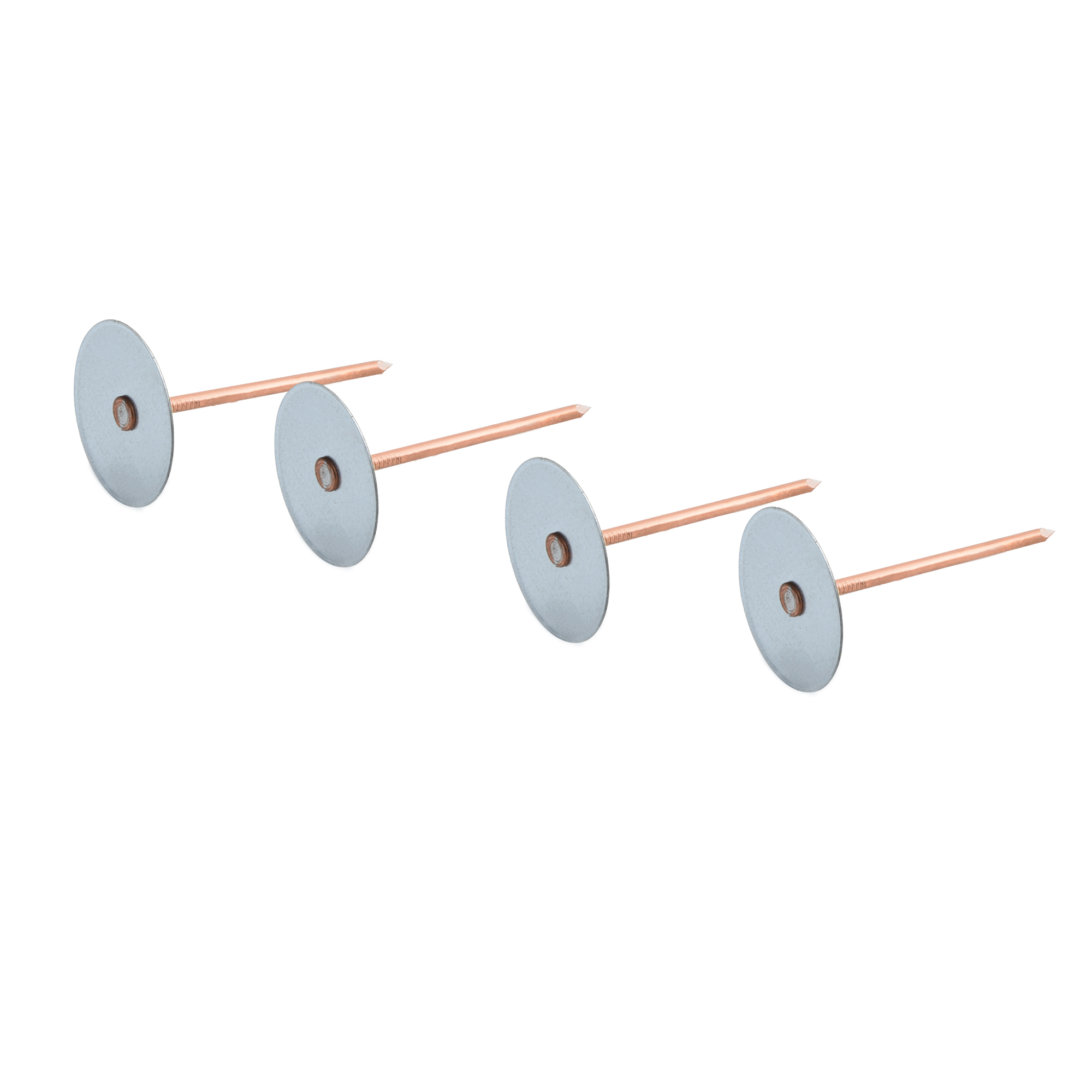

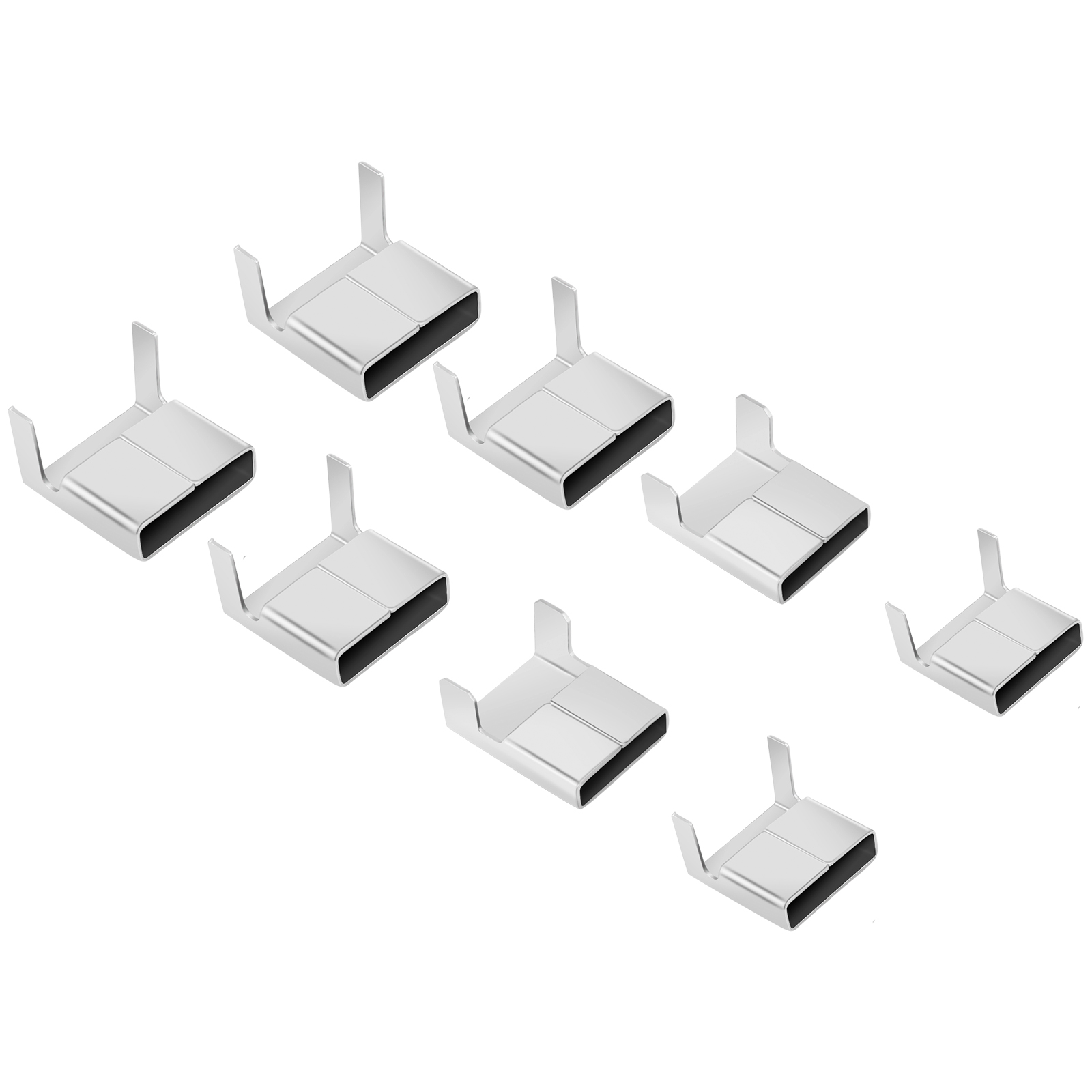

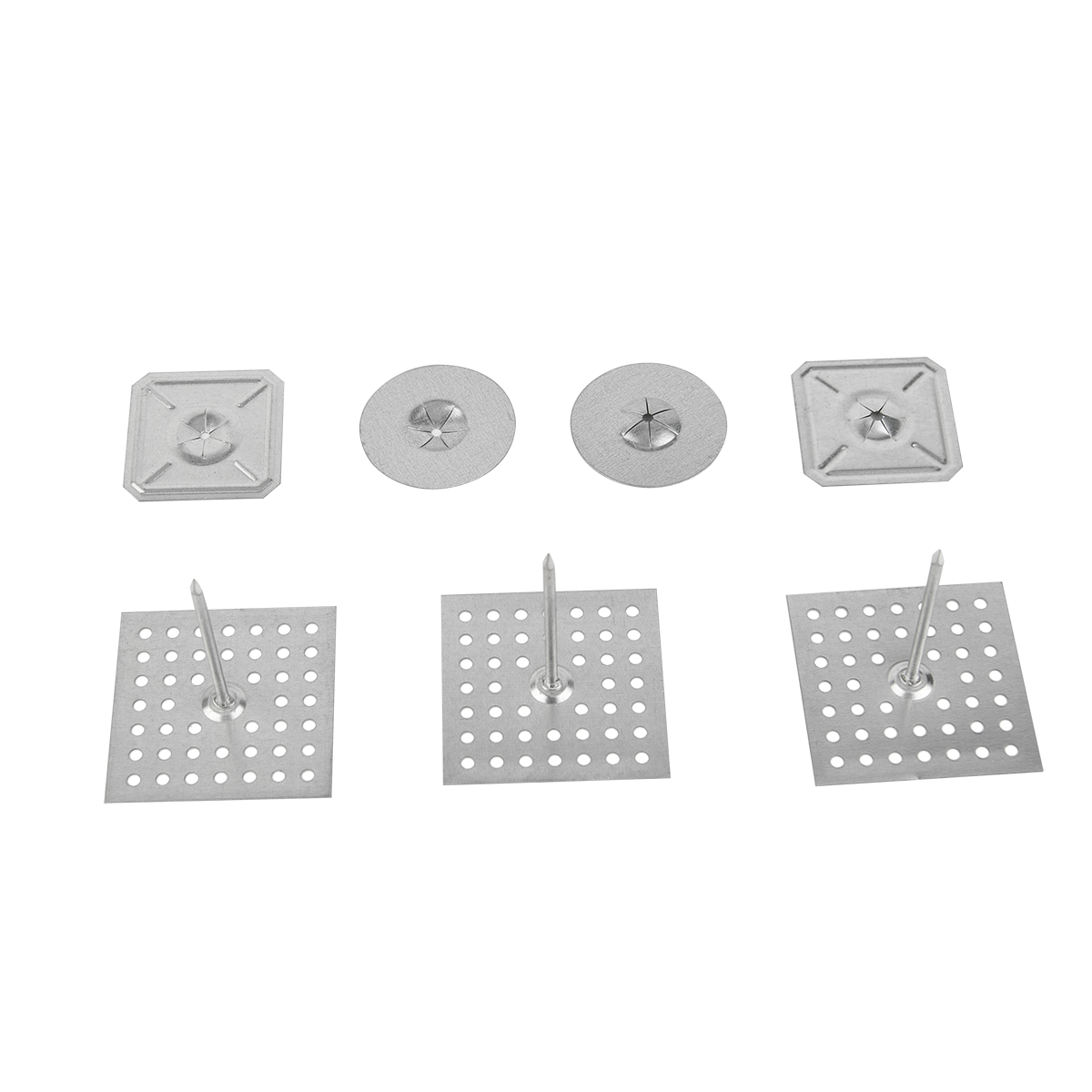

1. Structural shape: The design of the Cup Head Weld Insulation Pins is one of its most important features. The cup head is usually disc-shaped or hemispherical, with the purpose of dispersing the pressure applied to the insulation material and avoiding nails from penetrating or damaging the material. The edge of the cup head may have special textures or grooves to increase the contact area with the insulation material, thereby improving the fixing effect. The pin part is designed as a slender metal rod, and its diameter and length can be customized according to specific needs to accommodate insulation materials of different thicknesses and types.

2. Material selection: Cup Head Weld Insulation Pins typically use metal materials that are resistant to high temperatures and corrosion, such as stainless steel or alloys. These materials can maintain their mechanical properties and stability under high temperature and harsh environmental conditions. Choosing suitable materials is crucial for ensuring the long-term service life and reliability of nails. For example, stainless steel material can effectively resist high temperatures and chemical corrosion, extending the service life of nails.

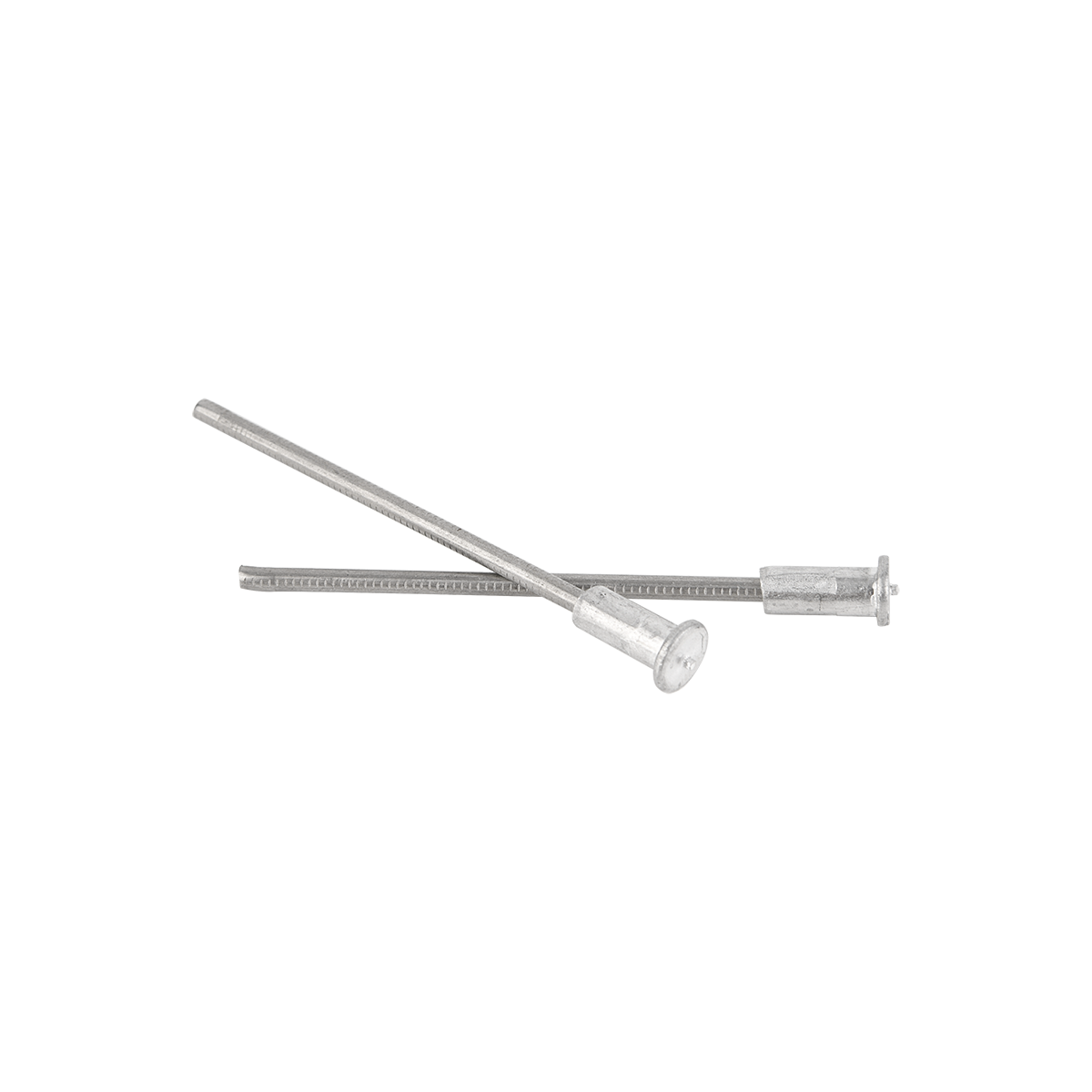

3. Welding technology: The welding part is a key design element of the Cup Head Weld Insulation Pins. The quality of welding technology directly affects the fixing effect and durability of nails. High quality welding treatment can ensure that the nails are firmly fixed on the surface of the equipment, preventing loosening or detachment. The materials and processes used in the welding process must also match the material of the nails to ensure optimal welding strength and stability.

4. Design optimization: To meet different application requirements, the design of Cup Head Weld Insulation Pins can be optimized in various ways. For example, the diameter and length of the pins can be adjusted according to the thickness of the insulation material to ensure that the nails can effectively penetrate and be fixed on the surface of the equipment. Meanwhile, the shape and size of the cup head can also be optimized to accommodate different types of insulation materials and installation conditions.

Overall, the design of Cup Head Weld Insulation Pins provides reliable fixation and durability while meeting the requirements of industrial environments. These design considerations work together to enable nails to perform well under various harsh conditions, ensuring efficient operation and long-term stability of the equipment.