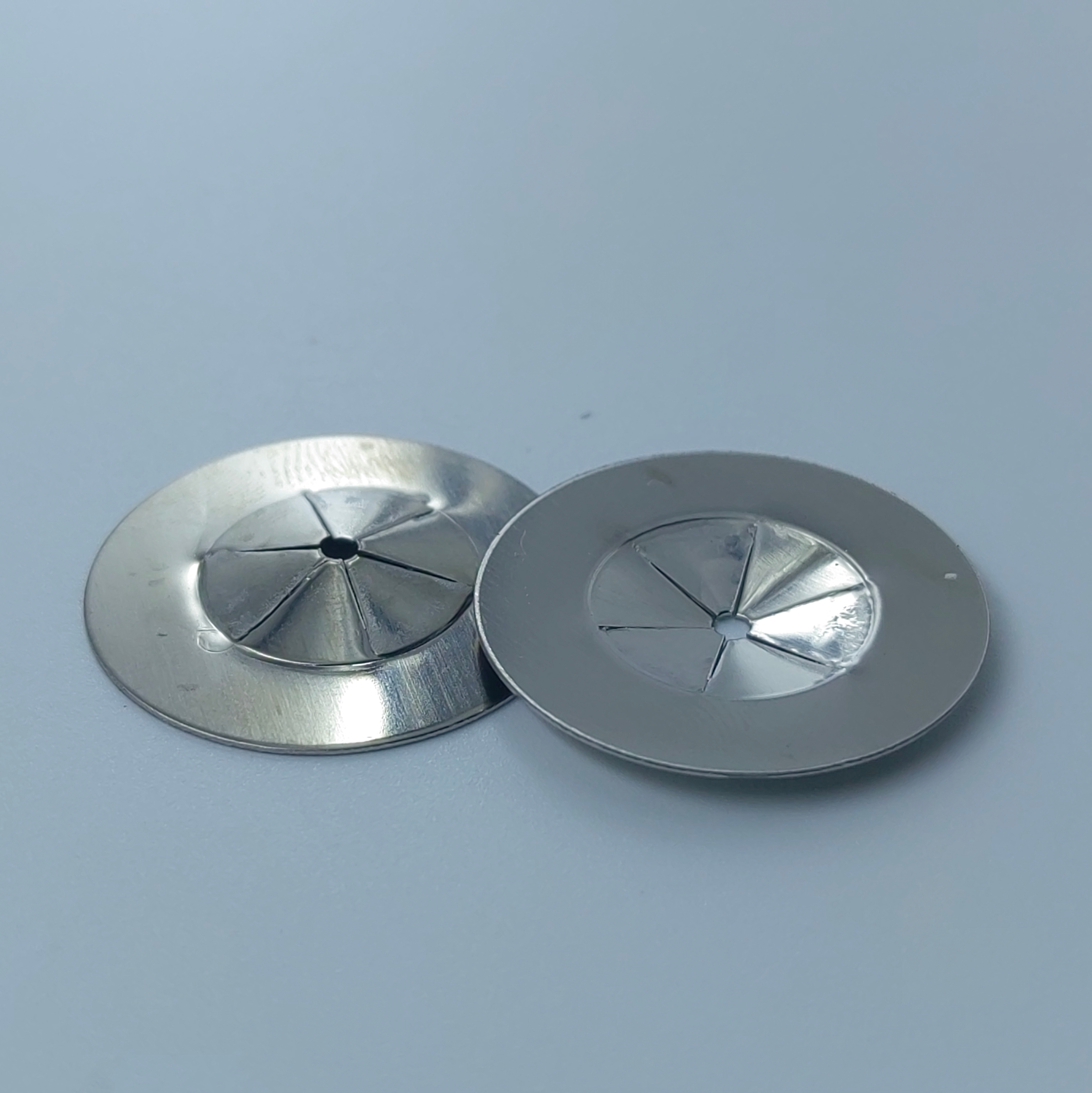

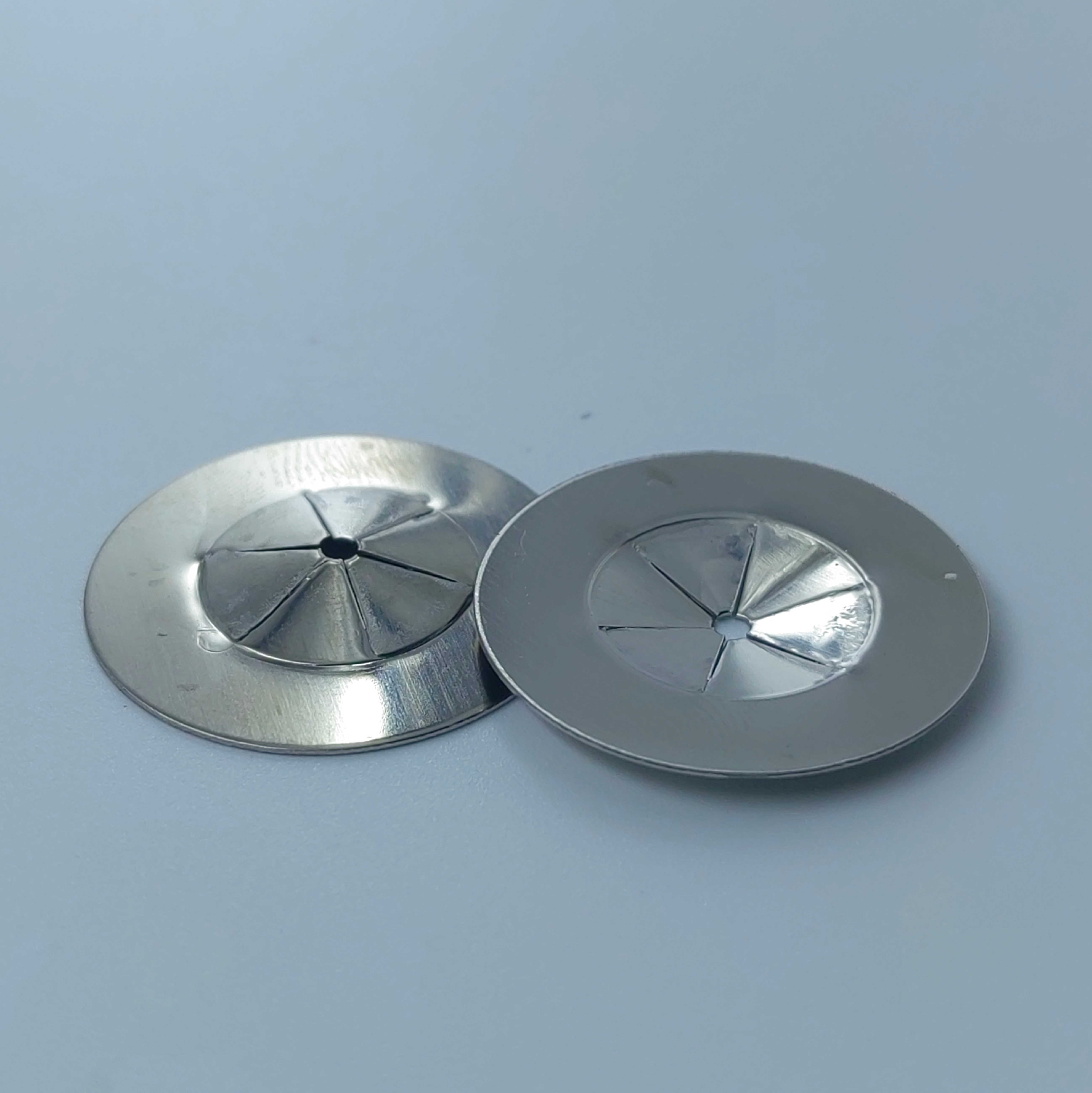

Insulation Spring Washers Structure

The structural design of the insulated spring washer aims to balance elasticity, insulation, and durability, mainly including the following components:

Contact

Product Detail

The structural design of the insulated spring washer aims to balance elasticity, insulation, and durability, mainly including the following components:

1. Spring section :

The spring part is the core of the insulated spring washer, usually made of spring steel or other elastic materials. This section provides elasticity and cushioning functions, allowing the gasket to absorb vibrations and impact forces during assembly. The form of spring design can be corrugated, spring shaped, or other specially designed structures to meet different application needs.

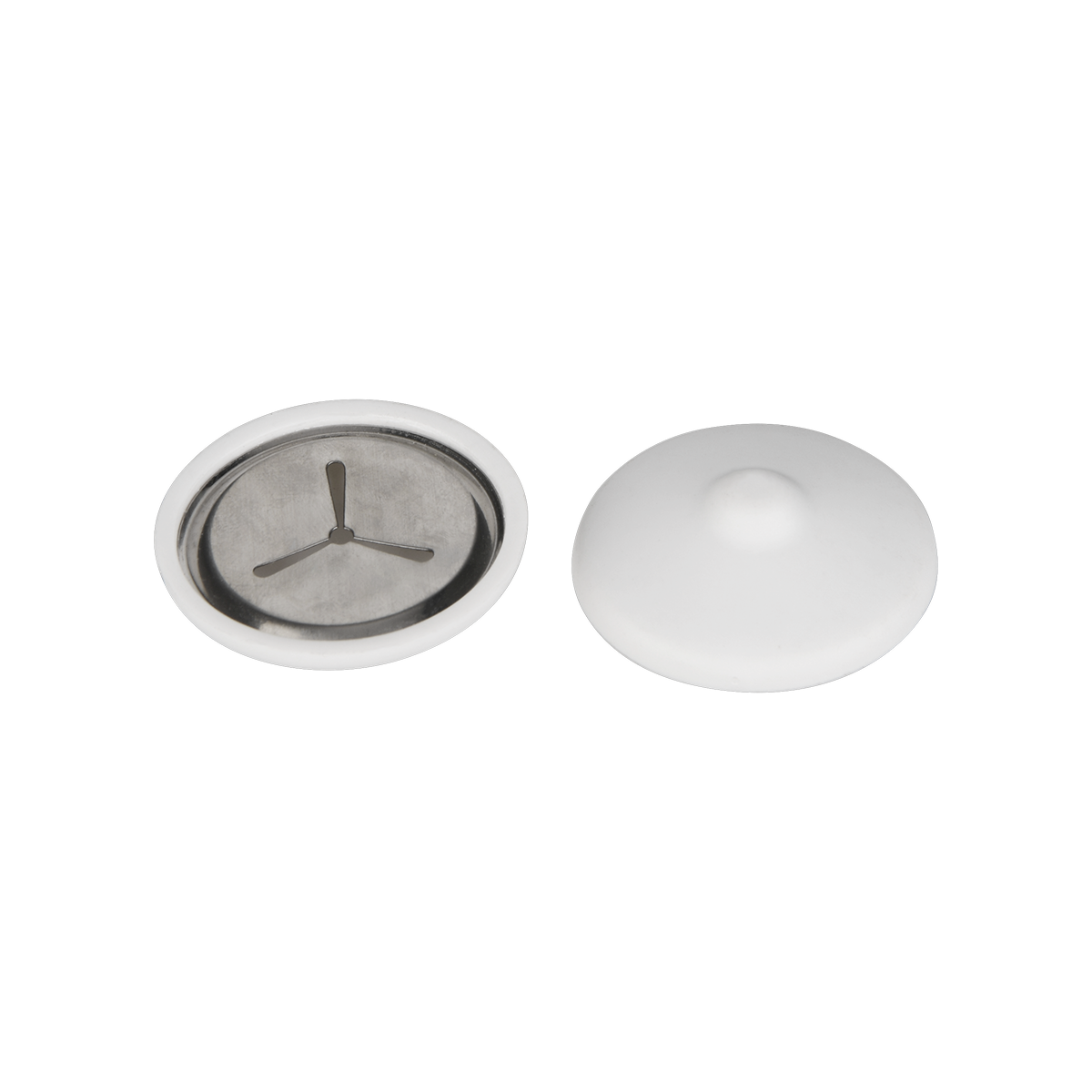

2. Insulation material layer :

Insulated spring washers typically contain a layer of insulating material, such as rubber, plastic, or other insulating composite materials. The main function of this layer of material is to provide electrical insulation and prevent short circuits or interference between electrical conductors. The thickness and type of insulation material are selected according to specific application requirements to ensure optimal insulation performance.

3. Outer diameter and inner diameter :

The outer and inner diameter design of insulated spring washers is very important, directly affecting their adaptability and installation performance. The outer diameter usually matches the aperture of the matching fastener, while the inner diameter needs to conform to the diameter of the fastener. Appropriate size design can ensure that the gasket provides effective support and insulation between the fastener and the installation surface.

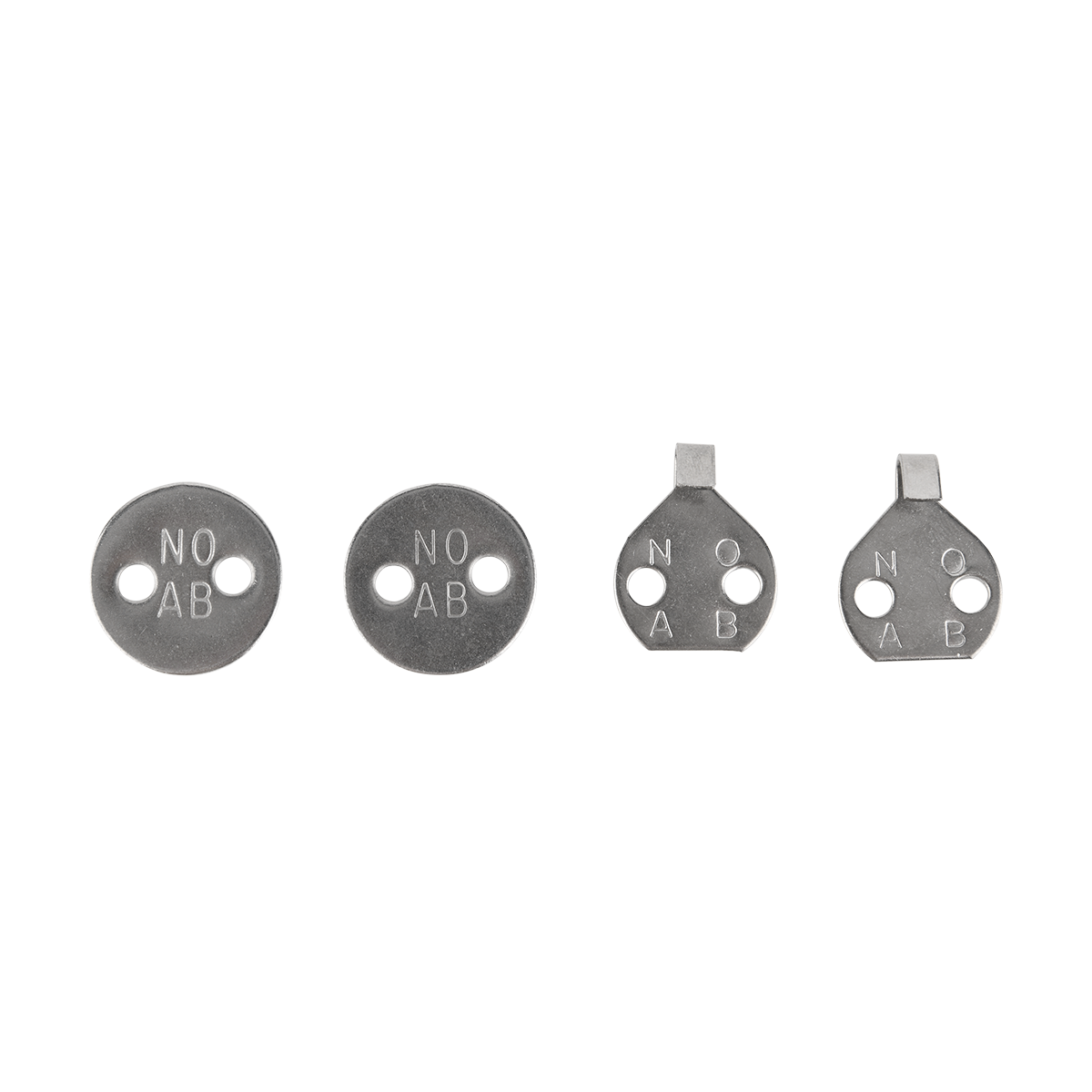

4. Surface Treatment :

The surface of insulated spring washers is usually treated with special treatments such as galvanizing or coating to improve their corrosion resistance and durability. This treatment can prevent the gasket from being damaged due to environmental factors during long-term use, ensuring its long-term stable performance.

5. Shape and Design :

The shape of the insulated spring washer can be designed according to specific applications, such as flat shape, groove shape, or corrugated shape. Different designs can provide varying degrees of elasticity and insulation effects to meet various practical usage needs.

Overall, the insulated spring washer, through its unique structural design, can provide elastic buffering, insulation protection, and anti loosening while ensuring the stability and safety of the equipment.