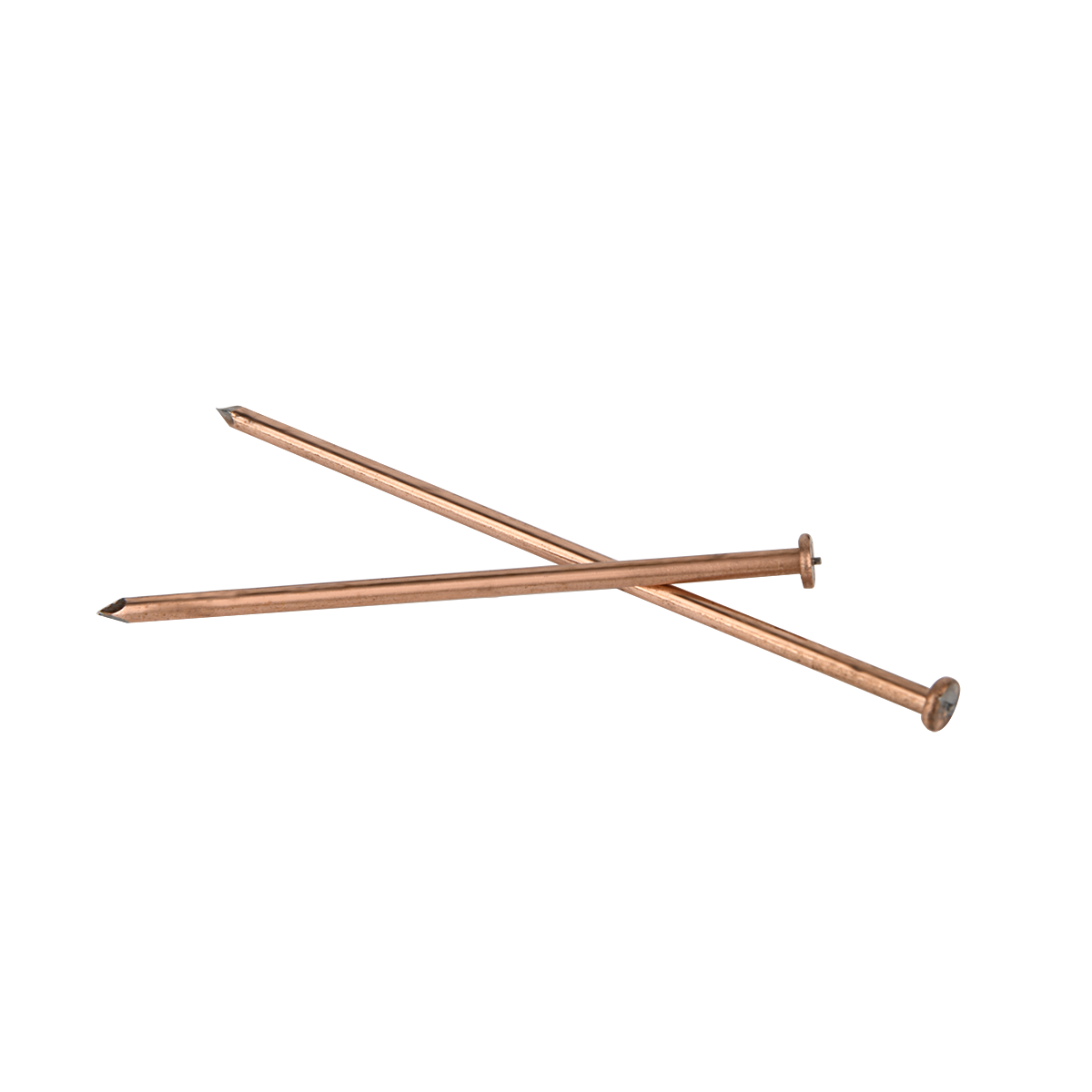

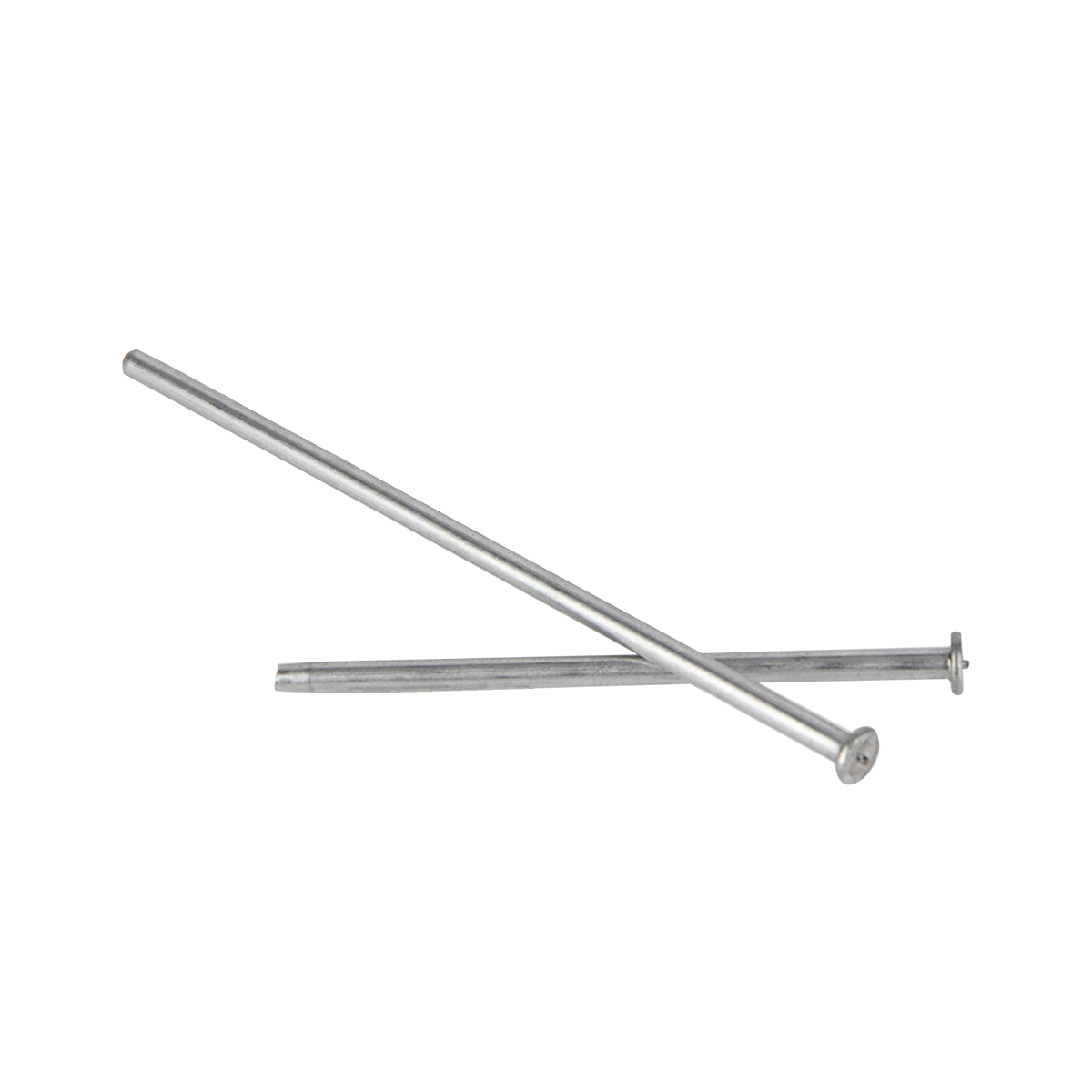

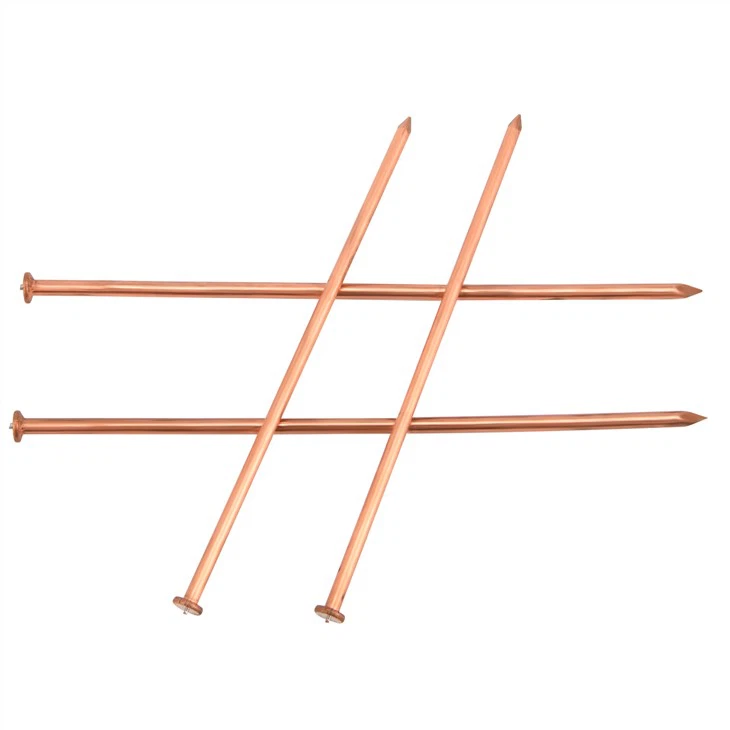

Curtain Wall Engineering CD Weld Insulation Pins

Curtain Wall Engineering CD weld insulation pins play a crucial role in the design and performance o

Contact

Product Detail

Curtain Wall Engineering CD weld insulation pins play a crucial role in the design and performance of curtain wall systems. These pins are an integral part of ensuring the functionality, energy efficiency, and durability of modern building facades.

In curtain wall engineering, insulation is a key consideration to regulate temperature, reduce energy consumption, and prevent condensation. CD weld insulation pins provide a vital link between the various components of the curtain wall, while maintaining the necessary electrical and thermal insulation. For example, they prevent the transfer of heat and cold between the exterior and interior of the building, contributing to a more comfortable indoor environment and lower energy costs.

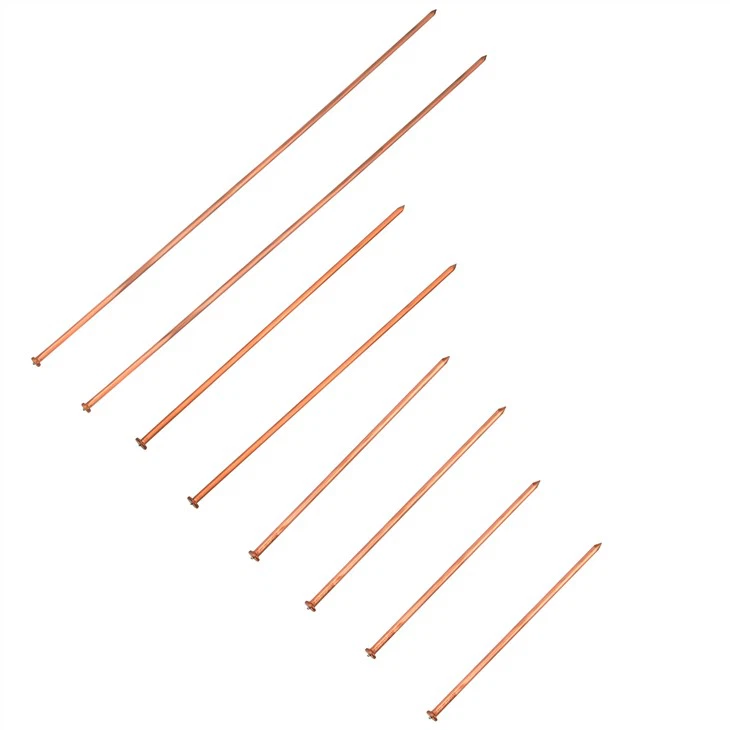

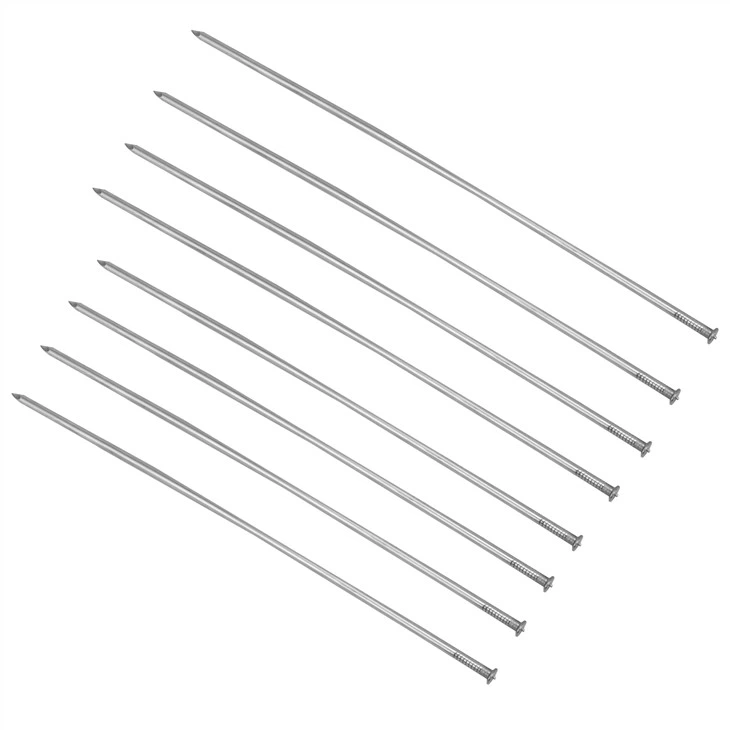

The materials chosen for these insulation pins in curtain wall applications need to possess specific properties. High-quality polymers or composites that offer excellent insulation characteristics, as well as resistance to weathering, UV radiation, and chemical exposure, are typically preferred. These materials ensure that the pins can withstand the harsh outdoor conditions and the long-term demands of the curtain wall system.

The design of the CD weld insulation pins is tailored to the unique requirements of curtain wall assemblies. They are engineered to accommodate the different materials and profiles used in the curtain wall, providing a secure and stable connection. The pins' shape and size are optimized to distribute loads evenly and minimize stress concentrations, which is crucial for the overall structural integrity of the curtain wall.

Moreover, in high-rise buildings or structures exposed to strong winds, the insulation pins need to withstand dynamic forces. They are designed to absorb vibrations and shocks, preventing damage to the curtain wall and maintaining its appearance and performance over time.

Quality control is of paramount importance in the production and installation of these pins. Rigorous testing is conducted to verify their insulation properties, mechanical strength, and dimensional accuracy. This ensures that the pins meet the strict standards and specifications of the curtain wall engineering industry.

To illustrate, in a large commercial building with a curtain wall facade, the proper functioning of the CD weld insulation pins helps to maintain a consistent indoor temperature, reduces the load on the HVAC system, and extends the lifespan of the curtain wall by protecting it from the elements.

In conclusion, Curtain Wall Engineering CD weld insulation pins are an essential component in achieving aesthetically pleasing, energy-efficient, and structurally sound curtain wall systems for modern buildings.